PU Conveyor Belt High Quality Food Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PU Conveyor Belt High Quality Food Grade

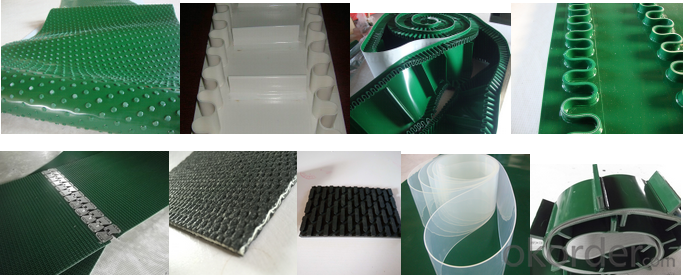

PVC conveyor belt,PU conveyor belt and some special material,such as silica gel, rubber and etc.

Food Grade PU conveyor Belt

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Our Company:

Pls contact me freely if any inquiry,thank you!

- Q: Can olive nets be used for olive tree pruning purposes?

- No, olive nets are not typically used for olive tree pruning purposes. Pruning involves trimming and shaping the tree's branches and foliage, while olive nets are primarily used for harvesting olives by catching the ripe fruits as they fall off the tree.

- Q: Plastic molding is what to do, how the process?

- The plastic molding is various forms (such as powder, granules, solution and dispersion) of plastic products or parts required for the shape of. As many as 30 kinds of molding method.

- Q: Can olive nets be used in olive groves with different tree varieties?

- Yes, olive nets can be used in olive groves with different tree varieties. Olive nets are designed to be versatile and can be used in various types of olive groves, regardless of the tree varieties present. They provide effective protection against birds and insects, helping to ensure a healthy and productive harvest across different olive tree varieties.

- Q: How do olive nets affect the growth and health of olive trees?

- Olive nets have a positive impact on the growth and health of olive trees. These nets protect the trees from pests and birds that can damage the fruits or eat them. By preventing these threats, olive nets promote a healthier and more abundant yield. Additionally, these nets create a more controlled environment around the trees, reducing the risk of diseases and ensuring optimal growing conditions. Overall, olive nets contribute to the overall well-being and productivity of olive trees.

- Q: Can olive nets be used to protect against frost damage?

- Yes, olive nets can be used to protect against frost damage. These nets are commonly used in olive groves to shield the trees from frost during cold weather conditions. The nets act as a barrier, preventing direct contact between the frost and the olive trees, thus reducing the risk of frost damage.

- Q: How do you protect olive nets from rodents or other pests?

- To protect olive nets from rodents or other pests, there are a few effective measures that can be taken. Firstly, a physical barrier such as a wire mesh or fence can be installed around the olive trees to prevent access to the nets. This barrier should be buried a few inches into the ground to prevent burrowing. Additionally, using rodent traps or bait stations strategically placed near the trees can help control the population of rodents. Another approach is to use natural repellents like essential oils or predator urine, which can deter pests from approaching the nets. Regular monitoring and maintenance are essential to promptly address any pest issues and ensure the nets remain intact and effective.

- Q: How do you prevent olives from rotting under the olive net?

- To prevent olives from rotting under the olive net, proper airflow and drainage are essential. Ensuring that the net is properly installed and secured, allowing air circulation, will help prevent moisture build-up and rot. Additionally, regularly inspecting the olives, removing any damaged or rotten ones, and providing adequate sunlight exposure will help maintain their freshness and prevent rotting.

- Q: Are olive nets suitable for both young and mature olive trees?

- Yes, olive nets are suitable for both young and mature olive trees. Olive nets can be used to protect the olives from birds and other animals, regardless of the age of the tree. They are effective in preventing damage to the olives, ensuring a successful harvest for both young and mature olive trees.

- Q: What is the role of calcium carbonate in plastics?

- Improving the dimensional stability of plastic productsThe addition of calcium carbonate plays a skeleton role in plastic products, and has a great effect on the stability of plastic product size.

- Q: Can olive nets be customized for specific grove sizes?

- Yes, olive nets can be customized for specific grove sizes. Olive nets come in various sizes and can be tailored to fit the dimensions of different olive groves, ensuring an efficient and effective harvesting process.

Send your message to us

PU Conveyor Belt High Quality Food Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords