Printed Prepainted Galvanized Steel Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

1. AZ zinc coil PPGI PPGL GI GL

2. Size: 0.13-1.2X600-1250mm

3. Zinc: 60-275g

4. Competitive price

We produce and supply various kinds of steel coils, steel strips. Free sample can be provided. Welcome to contact for further information.

| NAME | ppgi color coated galvanized steel coil | GALVANIZED | GALVALUME/ALUZINC |

| CERTIFICATE | ISO9001 | ||

| STANDARD | GB/T-12754 JIS G 3312 EN 10169 ASTM A755 | GB/T-2518 JIS G 3302 EN 10142/10427 ASTM A653 | GB/T-14798 JIS G 3321 EN 10215 ASTM A792 |

| GRADE | SGCC DX51D+Z DX53D+Z SGCH CGCD1-CGCD3 CGC340-CGC570 | SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D+Z DX53D+Z | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

| MODEL NO | 0.13MM -1.2MM *600-1250MM | (0.12-1.5)*600-1250MM | 0.16MM -1.5MM *600-1250MM |

| ZINC OR AZ Coating | 60-275g/m2 | 60-275g/m2 | 60-150g/m2 |

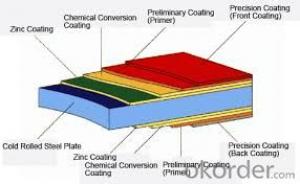

| Painting | top paint 16-25um back paint 7-10 | ||

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating | |

| APPLICATION | Structural use ,roofing, corrugated roofing, commercial use, household appliance, industry, family | ||

| SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

- Q: What are some characteristics of steel.

- Characteristics Of Steel Hardening. - The characteristic difference between steel and pure wrought iron is as follows: - When steel is raised to a red heat and then suddenly cooled, it becomes hard and brittle. This process, which is known as hardening, has no effect upon pure wrought iron. Tempering is a characteristic of steel which distinguishes it from cast iron. If steel has been hardened by being heated and suddenly cooled, as above described, it may be softened again by applying a lower degree of heat and again cooling. This is known as tempering. Cast iron, on the contrary, though it is hardened by the first process, cannot be softened by the second. When a bar of steel is struck it gives out a sharp metallic ring, quite different from the sound produced by striking wrought iron. Other characteristics of steel are its great elasticity and its retention of magnetism.

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils vary depending on factors such as the specific type of steel, the intended use, and industry standards. Generally, steel coils can range in width from a few inches to several feet, with thicknesses typically ranging from a fraction of an inch to several millimeters. The inner diameter of a steel coil can also vary, with common sizes being 20 inches and 24 inches. Ultimately, the dimensions of steel coils are determined by the specific needs and requirements of the end user.

- Q: When steel is cast, does it become weaker/more brittle or anything of this nature? what are the side effects of steel casting on the steel itself?How can you correct these?

- Cast steel uses specific alloys of steel designed to improve the casting process. It has a specific strength and toughness range based on the alloying ingredients. It physical properties are a bit different from rolled steel. The primary problems with casting steel are porosity and voids or spaces where the mold is not completely filled with molten steel. These do not effect the basic strength of the steel but they can degrade the ability of the casting to function as designed.

- Q: Two different shaving razors I'm looking to buy have different specs. in terms of the metals used for the blade; one being 1045 surgical stainless steel, the other 440 stainless (not sure if its A B or C, but probably 440A or 440B because it's not specified). So which one is better for the intended use as a shaving razor?

- 1045 stainless is better

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common manufacturing process used to shape and cut steel coils into desired forms and designs.

- Q: What are the common coil thickness tolerances?

- The common coil thickness tolerances can vary depending on the specific industry and application. However, typical tolerances for coil thickness range from +/- 0.001 inches to +/- 0.005 inches.

- Q: What are the different surface treatments for steel coils?

- There are several different surface treatments available for steel coils, depending on the desired outcome and application. Some of the most common surface treatments for steel coils include: 1. Hot-dip galvanizing: This process involves immersing the steel coils in a bath of molten zinc, which forms a protective layer on the surface of the steel. Hot-dip galvanizing provides excellent corrosion resistance and is often used for outdoor applications. 2. Electro-galvanizing: Similar to hot-dip galvanizing, but instead of immersing the steel coils in molten zinc, a thin layer of zinc is electroplated onto the surface of the steel. Electro-galvanizing provides good corrosion resistance and is commonly used for indoor applications. 3. Powder coating: This process involves applying a dry powder to the surface of the steel coils, which is then heated and cured to form a hard, durable coating. Powder coating provides excellent corrosion resistance and is available in a wide range of colors and finishes. 4. Paint coating: Steel coils can also be coated with a liquid paint, which provides both corrosion resistance and aesthetic appeal. Paint coatings can be applied in various thicknesses and finishes, depending on the desired look and level of protection required. 5. Phosphating: Phosphating is a chemical treatment that involves immersing the steel coils in a phosphate solution. This process creates a thin, adherent layer of phosphate on the surface of the steel, which enhances paint adhesion and improves corrosion resistance. 6. Chromate conversion coating: Also known as chromating or passivation, this process involves immersing the steel coils in a solution containing chromium salts. Chromate conversion coatings provide excellent corrosion resistance and also act as a primer for subsequent paint or powder coating. 7. Zinc-nickel plating: This surface treatment involves electroplating a layer of zinc-nickel alloy onto the steel coils. Zinc-nickel plating provides superior corrosion resistance compared to pure zinc plating and is often used in demanding environments. These are just a few of the many surface treatments available for steel coils. The choice of treatment depends on factors such as the application, desired level of corrosion resistance, aesthetic requirements, and budget. It is important to carefully consider the specific needs of the project and consult with experts to determine the most suitable surface treatment for steel coils.

- Q: So I was thinking about doing corset waist training and I wanted to know where I can get a real steel boned corset?

- Hi, okorder / There are 3 types of corsets: Fashion corsets, Authentic corsets and Waist training corsets. The fashion corsets are designed for light enclasping of body. They are made with plastics bones usually. The authentic corsets can reduce your waist size about 4 - 5 and the waist training corsets about 6. They both are made with steel spirals and flat bones. The waist training corsets are recommended for experienced wearers only. Look on info pages of the seller. The corsets reinforced with plastic bones are cheap with low durability.

- Q: Monopolistic competition means all of their products are identical like things in supermarket like milk. There are no high barriers to entry. Oil and steel are all same in all industries.

- While oil and steel may seem to be all the same, they are really not. There are many different grades of crude oil and many different types of steel.

- Q: How did the growth of the steel industry influence the development of other industries?

- At least three ways: 1. Steel as a material that other industries could use to do things that couldn't be done before (for example, construction (skyscrapers, long bridges, etc.)) or could now be done at much lower cost and hence increased the size of the industry (automobiles, bearings, etc.)

Send your message to us

Printed Prepainted Galvanized Steel Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords