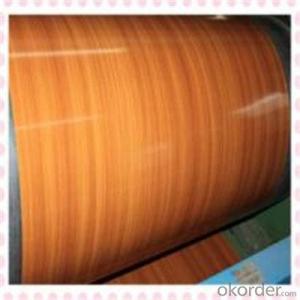

PRINGTING STEEL---WOODEN PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pattern Printed Coil Steel

Product Description :

Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Thickness | 0.16mm-0.7mm |

Width | 1250mm or under |

Tolerance | thickness+/-0.01mm |

Surface treatment | galvanized / galvalumized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

Anti-MEK Wiping | ≥100times |

Zinc coating | 40-180g |

Type of coating structure | 2/1 or 2/2 coating, or customized |

Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

Color | customized |

Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- glass what

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wound around a laminated steel core to create an electromagnet that generates the magnetic field required for the motor's operation. The steel coils, when energized with electric current, produce a magnetic field that interacts with the stator and rotor to facilitate the conversion of electrical energy into mechanical energy.

- Q: What are the different methods of tension leveling for steel coils?

- There are several methods of tension leveling for steel coils, including roller leveling, stretcher leveling, and temper leveling. In roller leveling, the coil passes through a series of rollers that apply pressure to remove the internal stresses and flatten the material. Stretcher leveling involves stretching the coil beyond its yield point to remove the unevenness and then allowing it to spring back to a flat state. Temper leveling uses heat treatment to relieve the internal stresses and bring the coil to a flat condition. These methods provide different ways to achieve a level and flat surface for steel coils.

- Q: Are steel buildings more durable than concrete building?

- both okorder /

- Q: What are the standard dimensions and weights of steel coils?

- The standard dimensions and weights of steel coils can vary depending on the specific type and grade of steel being used, as well as the manufacturing process and intended application. However, there are some common industry standards that can provide a general idea of the dimensions and weights of steel coils. In terms of dimensions, steel coils typically have a standard width ranging from 600mm to 2000mm or more, with the most common widths being 1000mm, 1250mm, and 1500mm. The inner diameter of the coil, also known as the core or mandrel, is usually around 508mm (20 inches) or 610mm (24 inches). The outer diameter of the coil, also known as the outside diameter or OD, can vary widely depending on the thickness and width of the coil, but it is typically in the range of 1200mm to 2000mm. As for weights, steel coils are measured in terms of their gross weight, which includes the weight of the coil itself along with the steel material it contains. The weight of a steel coil can range from a few hundred kilograms to several tonnes, depending on the thickness and width of the coil. For example, a coil with a thickness of 0.5mm and a width of 1000mm may weigh around 5-6 tonnes, while a coil with a thickness of 3mm and a width of 1500mm can weigh around 20-25 tonnes. It's important to note that these dimensions and weights are just general guidelines and may vary depending on the specific requirements and standards of different industries and manufacturers. Therefore, it is always recommended to consult the relevant specifications or contact the manufacturer for accurate and up-to-date information regarding the dimensions and weights of steel coils.

- Q: What are the common problems faced during steel coil production?

- Some common problems faced during steel coil production include surface defects such as scratches or dents, dimensional inconsistencies, coil breakage, edge wave formation, and coil slitting issues. Other challenges may include coil corrosion, improper coil cooling, and quality control issues.

- Q: How are steel coils used in the manufacturing of flooring materials?

- Steel coils are used in the manufacturing of flooring materials by being formed into sheets or strips and then processed through various techniques such as cutting, bending, and shaping to create the desired flooring products. The steel coils provide strength, durability, and stability to the flooring materials, ensuring long-lasting and reliable flooring solutions.

- Q: who, when and where was dual phase steel invented?

- Looking okorder /... but I would note that this stuff seems an awful lot like the techniques that have been used for making high quality swords and cutting tools for thousands of years including the famed Damacas steel. In these, the steel is heated and slowly cooled (annealed) to produce the tough matrix, then the piece is reheated and quenched to produce the hard edge. What Dual-phase seems to do is bring the process to bulk manufacture.

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

- Q: Can steel coils be stacked on top of each other?

- Yes, steel coils can be stacked on top of each other.

Send your message to us

PRINGTING STEEL---WOODEN PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords