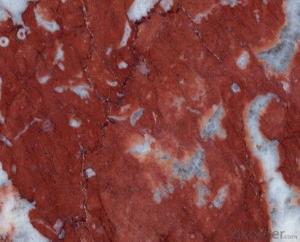

PRINGTING STEEL---MARBLE PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,GB,JIS | Grade: | SGCC | Thickness: | 0.2mm-1.2mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | EAST STEEL | Type: | Steel Coil |

| Technique: | Cold Rolled | Surface Treatment: | Coated | Application: | Other |

| Special Use: | Wear Resistant Steel | Width: | 800mm-16000mm | Length: | as customer's required |

Specifications

1) Manufacturer of Galvanized Steel Coil

2) Superior quality with moderate price

3) Wide size range

4) Quick delivery

items | thickness | TYPE | Features |

Protection film | 50μm | polyethylene | Protecting from scratchs and contamination (Option) |

Finished coat | 10μm | PVDF | Protecting printed layer and enhances the appearance of the surfaces |

1μm | Ink, Polyester | Various printing patterns,3 color overprint | |

Top coat | 20μm | Polyester Fluorine | Chemical resistance, formability and patterns multiformity |

Primer coat | 5μm | Polyester | workability, corrosion resistance and adhesion to the primer coating |

Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

substrate | 0.2-1.2mm | GI.GL.AL | GI.GL,AL |

Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

Back coat | 5μm | Epoxy | corrosion resistance and adhesion to the substrate |

- Q: What are the different methods of punching steel coils?

- There are several methods of punching steel coils, including mechanical punching, hydraulic punching, and laser punching. Mechanical punching involves the use of a mechanical press with a punch and die set to create holes or shapes in the steel coil. Hydraulic punching utilizes hydraulic force to drive a punch through the coil, providing high precision and speed. Laser punching, on the other hand, uses a laser beam to cut or form holes in the steel coil, offering great flexibility and accuracy. Each method has its own advantages and suitability depending on the specific requirements of the application.

- Q: How do steel coils compare to other materials in terms of cost?

- Steel coils are generally more cost-effective compared to other materials due to their durability, versatility, and widespread availability in the market.

- Q: Procedures for sharpening a knife with the stone and the steel?

- The site listed above gives you a great step by step procedure on how to do this yourself. A Sharpening Steel is used to sharpen the fine edge of a knife. Many knives only need this done to have a refined edge. Any fine edge of a knife can have minor burrs that occur with normal use. To sharpen this type of edge, merely run the knife at an approximate 7-8 degree angle, away from yourself on the Sharpening steel repeatedly (no more than about 8-10 times each side, alternating each side as you go). Give the knife a quick wash, to remove any unwanted detritus, and you are ready to go. If you want to resharpen an entire knife, use a wet stone. Remember some stones have a natural oil in it, some do not. If you are already using a stone with oil, continue to use it with Mineral Oil as the lubricant. If it is a dry stone, use warm water. You'll never be able to change a stone once you use oil. Make sure its as flat as you can. Wet it with warm water, or the mineral oil, rub the knife away from yourself (on the coarse side) at a 5 degree angle on both sides. Alternating sides approximately 20-30 times each. Flip the stone over (dry finer side), and at a 6 degree angle, rub the knife blade toward you on both sides approximately 10 times on each side. Using either your Sharpening steel, or 550-600 coarse emory paper, rub the knife away from you 5-7 alternating times on each side at about a 7-8 degree angle. Clean the knife well. You now have a VERY sharp knife that will require this entire treatment ony 2-4 times a year at most. Otherwise, keep using the sharpening steel. I GUARANTEE this works best.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- go okorder and search for steel.......

- Q: Can steel coils be coated with anti-fingerprint materials?

- Yes, steel coils can be coated with anti-fingerprint materials. These coatings are designed to reduce the visibility of fingerprints and smudges, making the steel coils more resistant to marks and easier to clean.

- Q: How does adding carbon to Iron make it stronger? How does steel look the molecular structure in comparison to Iron? looking for a very scientific answer =]

- Cast Iron' is typically brittle, while 'Maleable Iron' has a small percentage of carbon which allows it to be hammered and formed. Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron. Steel is a crystalline structure of iron molecules interspersed with carbon molecules. This is properly known as cementite. The hardness and malleability of steel depends not only on the carbon content, but on how the carbon and iron molecules are arranged to one another. Internal stresses in the steel's crystalline structure will increase or decrease depending on the temperature it is subjected to and the rate at which molten steel is cooled. This 'tempering' can increase the strength of the steel at the expense of brittleness.

- Q: How are steel coils packaged for shipment?

- Steel coils are typically packaged for shipment by being tightly wound and secured with steel bands or straps. They are often placed on wooden skids or pallets to provide stability and protection during transportation. Additionally, protective covers or sheets may be used to shield the coils from moisture and other potential damages.

- Q: I'm analysing horse stirrups and would like to know the disadvantages to stainless steel? - thanks

- Stainless Steel has more advantages than disadvantages. But u asked for disadvantages so they r as follows i've given common disadvantages more can be found on Google. Disadvantages of Stainless Steel: Stainless steel tends to scratch and dent. Food, grease and fingerprints show very clearly on stainless steel, making frequent wiping and cleaning a necessity. High initial cost Difficult to fabricate, or in other words, it is not as malleable as other metals, say iron, and hence if not fabricated properly, results in costly re-work. Difficult to weld High cost of polishing etc. i.e. adding finishing touches for the market. there are advantages more than disadvantages. But u asked for disadvantages that's why i have given only disadvantages of stainless steel Hope what u want u got.

- Q: I am building a steel type competative team. my team so far isempolem, skarmory , Metagross, magnezone, lucario, ferrothorn.

- Good choice in pokemon. As for moves and EVs and all that... its kinda up to how exactly you wanna play your steel team, but heres what I can think up off the top of my head: Empoleon: Mixed Attacker. Swords Dance and Aqua Jet for strong priority attacking, with two special attacks (preferrably one water and one other non steel non water attack) Skarmory: Physical wall. Skarmory is know to be an amazing physical wall. So pump HP and defense EVs into it. Impish nature is best, and try to get Roost, Whirlwind, and Brave Bird on it. Stealth Rock or Spikes for entry hazard damage. Metagross: Physical attacker. Bullet Punch is nice since Metagross is kinda slow, and Hammer Arm is decent since it hardly cares about a speed drop. Earthquake and Zen Headbutt aren't bad either. Magnezone: Bulky Special Attacker. The teams a really physical one, so having a special attacker is nice so other physical walls don't mess you up too bad. Its main attacking moves should be Thunderbolt and Flash Cannon. Sturdy and Magnet Pull are both good abilities, which one you go with is up to you. Lucario: Physical Sweeper. Max out Lucario's Attack and Speed EVs, its defenses are too low for it to take repeated hits. Close Combat and Extremespeed are Lucario staples. The other 2 moveslots depend on you. An elemental punch is good for coverage. Earthquake... is Earthquake, its good to have. There's other options too. Ferrothorn: Ferrothorn has a number of options, usually involving its great bulk. Look this one up on Smogon. Other good steel types would include: Bronzong, Scizor, Forretress. Excadrill is good, but its far better in a sandstorm team than on an all steel team (Sand Rush+Swords Dance+Focus Sash+Attack=death). Hope this helps.

- Q: which cost more: ALLOY, GUNMENTAL OR STAINLESS STEEL. GIVE ME AN IDEA OF THE COST OF EACH.

- Titanium alloy is. Its the hardest metal in the world and takes about 6 months to produce. I sell titanium juliets for 350.

Send your message to us

PRINGTING STEEL---MARBLE PATTERN

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords