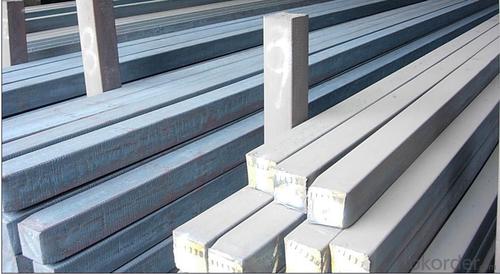

Prime quality square alloy steel billet 130mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime quality square alloy steel billet 130mm Q235

Description of Prime quality square alloy steel billet 130mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime quality square alloy steel billet 130mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime quality square alloy steel billet 130mm Q235

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Prime quality square alloy steel billet 130mm Q235

Product | Prime quality square alloy steel billet 130mm Q235 |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime quality square alloy steel billet 130mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the potential applications of steel billets in the chemical sector?

- Steel billets have several potential applications in the chemical sector. They can be used as raw materials for the production of various chemical compounds, such as stainless steel, which is widely used in the manufacturing of chemical processing equipment. Steel billets are also used to construct storage tanks, pipelines, and other infrastructure required for transporting and storing chemicals safely. Additionally, steel billets can be utilized in the fabrication of heat exchangers, reactors, and other equipment used in chemical reactions and processes. Overall, steel billets play a crucial role in supporting the chemical industry by providing robust and reliable materials for a wide range of applications.

- Q: What are the main factors affecting the thermal conductivity of steel billets?

- The main factors affecting the thermal conductivity of steel billets include the composition of the steel, its microstructure, temperature, and the presence of impurities or alloying elements.

- Q: Can steel billets be customized in terms of shape and size?

- Yes, steel billets can be customized in terms of shape and size. Steel billets are semi-finished products that are typically rectangular in shape and are used as raw material for various manufacturing processes. However, they can be altered to meet specific requirements by undergoing a process known as billet rolling or cross-rolling. During this process, the steel billets are passed through a series of specially designed rolls that apply pressure and force to reshape them. This allows for the customization of the billets into different shapes and sizes, such as square, round, or hexagonal, based on the desired end product. Additionally, the size of the steel billets can also be customized. The initial dimensions of the billets can be adjusted by either increasing or decreasing their length, width, and height. This flexibility in customization enables manufacturers to produce steel billets that best suit their specific production needs. In conclusion, steel billets can indeed be customized in terms of both shape and size through the process of billet rolling. This allows manufacturers to adapt the billets to their desired specifications, enabling them to create a wide range of products using steel as a raw material.

- Q: How are steel billets used in the production of automotive exhaust systems?

- Steel billets are an essential component in the production of automotive exhaust systems. These billets, which are solid blocks of steel, serve as the raw material for various parts and components of the exhaust system. The first step in using steel billets is to heat them in a furnace to a specific temperature in order to soften the steel and make it malleable. Once heated, the billets are then shaped and formed into different parts of the exhaust system, such as pipes, mufflers, and catalytic converters. This shaping process can be done through hot rolling, cold rolling, or extrusion, depending on the desired shape and properties of the component. After shaping, the steel billets are further processed to enhance their strength and durability. This can involve heat treatment processes like quenching and tempering, which improve the steel's hardness, toughness, and resistance to corrosion. These treatments ensure that the exhaust system components can withstand the harsh conditions they will be exposed to, such as high temperatures and corrosive gases. Once the steel billets have been shaped and treated, they are then assembled and welded together to form the final exhaust system. This involves joining the various components, such as pipes and mufflers, through welding techniques like arc welding or laser welding. These welding processes ensure that the components are securely connected, preventing any leaks or failures in the exhaust system. Overall, steel billets play a crucial role in the production of automotive exhaust systems by providing the necessary raw material for shaping and forming the various components. Their strength, durability, and resistance to high temperatures and corrosion make them an ideal choice for manufacturing exhaust systems that can withstand the demanding conditions of automotive use.

- Q: How do steel billets contribute to the manufacturing of tools and equipment?

- Tools and equipment manufacturing relies heavily on steel billets, which serve as a crucial component. These semi-finished steel products play a vital role in shaping and forming the final products used across different industries. To begin with, steel billets function as raw materials during the production of various tools and equipment. They act as the starting point for processes like forging, rolling, and extrusion. These processes involve heating and shaping the steel billets to achieve the desired form and dimensions of the tools and equipment. Furthermore, steel billets possess several advantages that make them suitable for tool and equipment manufacturing. The strength and durability of steel make it an ideal material for tools that need to endure heavy loads and harsh conditions. Additionally, the versatility of steel allows for the production of a wide range of tools and equipment, including cutting tools, machine parts, construction equipment, and automotive components. Moreover, steel billets can be easily machined and formed into complex shapes, enabling the production of intricate tools and equipment that meet specific requirements. The excellent machinability of steel allows for precise cutting, drilling, and milling processes, resulting in accurate dimensions and smooth surfaces. Additionally, steel billets can undergo heat treatment to enhance their mechanical properties, such as hardness and toughness. Processes like quenching and tempering can significantly improve the performance and longevity of tools and equipment. When combined with the inherent strength of steel, these processes ensure that the final products have the necessary strength, hardness, and wear resistance to effectively fulfill their intended functions. In conclusion, steel billets are indispensable in the manufacturing of tools and equipment due to their raw material capabilities and advantageous properties. They provide a reliable and versatile starting point for producing various tools and equipment, enabling the creation of durable, precise, and high-performance products that are vital to numerous industries.

- Q: What is the typical weight of a steel billet?

- The weight of a steel billet can differ based on its size and purpose, resulting in a range of common weights between 1,000 and 5,000 pounds (450 to 2,270 kilograms). This weight range grants flexibility in manufacturing processes and enables diverse applications across industries like construction, automotive, and manufacturing. It is crucial to acknowledge that distinct weight prerequisites might vary according to the steel billet's intended use and specifications.

- Q: Are steel billets subject to any international standards?

- Yes, steel billets are subject to international standards. The International Organization for Standardization (ISO) has established several standards that govern the production, quality, and dimensions of steel billets. These standards ensure that steel billets meet specific criteria and are suitable for use in various industries, including construction, manufacturing, and engineering. ISO standards, such as ISO 683-2 and ISO 16143-1, provide guidelines for the chemical composition, mechanical properties, and tolerances of steel billets. Additionally, international trade organizations, such as the International Trade Commission (ITC) and the World Trade Organization (WTO), may also establish regulations and standards for the import and export of steel billets to ensure fair trade practices and product safety. Therefore, steel billets are subject to international standards to ensure consistency, quality, and compliance across different countries and markets.

- Q: What are the different types of steel billet rolling defects?

- During the rolling process, various defects can arise in steel billets, which can have adverse effects on the final product's quality and integrity. The most commonly encountered types of steel billet rolling defects are as follows: 1. Surface cracks: These are minute cracks that manifest on the billet's surface. They can result from inadequate cooling or excessive rolling pressure. Surface cracks jeopardize the steel's strength and durability. 2. Center cracks: Inner core cracks occur when temperature control during the rolling process is incorrect. Center cracks can lead to structural weaknesses and reduced steel performance. 3. Scalloping: Scalloping refers to the formation of shallow depressions or grooves on the billet's surface. It usually arises due to uneven or improper rolling pressure distribution. Scalloping negatively impacts the steel's appearance and surface quality. 4. Lamination: Lamination defects involve the separation of layers within the billet. They can be caused by the presence of impurities or inclusions in the steel, as well as inadequate heating or rolling conditions. Lamination defects weaken the steel and increase the risk of failure. 5. Wavy edges: Wavy edges occur when the billet's edges become uneven or distorted during rolling. This can be the result of improper alignment or uneven pressure distribution. Wavy edges affect the steel's dimensional accuracy and overall quality. 6. Surface defects: Surface defects encompass scratches, pits, or other imperfections on the billet's surface. They may occur due to insufficient cleaning or handling procedures, as well as improper rolling conditions. Surface defects impact the steel's appearance and surface quality. In conclusion, these steel billet rolling defects hold significant implications for the final product's quality, performance, and safety. Manufacturers must closely monitor the rolling process and implement appropriate quality control measures to minimize the occurrence of these defects.

- Q: What are the different types of surface coating methods used for steel billets?

- Steel billets commonly undergo various surface coating methods to improve their durability, corrosion resistance, and overall performance. Some frequently utilized techniques for coating steel billets include: 1. Hot-dip galvanizing: Immersing the steel billets in molten zinc forms a protective layer, ensuring excellent durability and preventing corrosion. 2. Electroplating: Electrochemically depositing a thin layer of metals like zinc, nickel, or chromium onto the surface of the steel billets enhances corrosion resistance and improves aesthetics. 3. Powder coating: Applying a dry powder onto the steel billets' surface and subsequently heating it creates a protective layer. This method offers exceptional durability, chemical resistance, and a wide range of color options. 4. Paint coating: A liquid paint is applied to the steel billets, forming a protective layer that provides corrosion resistance. This technique allows for customization with different colors and finishes. 5. Thermal spray coating: A thermal spray gun is used to spray molten or powdered metals onto the steel billets' surface. This coating provides outstanding wear resistance, corrosion protection, and can be customized with various materials. 6. Anodizing: While primarily used for aluminum billets, anodizing can also be applied to steel. This electrochemical process creates an oxide layer on the steel billets' surface, enhancing corrosion resistance and providing a decorative finish. Each of these coating methods has its own set of advantages and disadvantages, and the selection depends on factors such as the desired protection level, aesthetics, and specific requirements of the steel billets.

- Q: How is a steel billet made?

- A steel billet is typically made through a process called continuous casting, which involves several steps. First, the raw materials for steel production, such as iron ore, coal, and limestone, are gathered and processed. These materials are then transformed into molten pig iron in a blast furnace. The molten pig iron is then transferred to a basic oxygen furnace or an electric arc furnace, where it undergoes further refining. In these furnaces, impurities such as carbon, sulfur, and phosphorus are removed, and alloying elements such as manganese, chromium, and nickel may be added to achieve desired properties. Once the molten steel is chemically balanced and refined, it is ready for casting. The steel is poured into a water-cooled copper mold, known as a continuous caster. As the molten steel flows into the mold, it solidifies and takes the shape of a long rectangular or square billet. During the casting process, water is circulated through the mold to rapidly cool the steel and facilitate solidification. This controlled cooling helps to ensure the billet has a consistent structure and desired mechanical properties. After solidification, the billet is cut into predetermined lengths using a torch or a shear. These billets can range in size, depending on their intended use, and may weigh several tons. Once cut, the billets can be further processed through rolling, forging, or other shaping methods to create various steel products such as bars, rods, tubes, or structural shapes. Overall, the production of a steel billet involves transforming raw materials into molten steel, refining it, and then casting it into a solid shape through continuous casting. The resulting billet serves as a starting point for the production of a wide range of steel products used in various industries.

Send your message to us

Prime quality square alloy steel billet 130mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords