Prime quality prepainted galvanized steel 720mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Specifications

Commodity Name: Prepainted Galvanized Steel Coil

Standard: AISI, ASTM, DIN, GB, JIS

Grade: TDC52D+Z

Thickness 0.13-8.0mm

Width:600mm-1350mm

Zinc Coating:275g/m2

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

- Q: Are steel billets used in the manufacturing of construction machinery?

- Yes, steel billets are commonly used in the manufacturing of construction machinery. Steel billets are semi-finished products that are used as raw materials in various industries, including construction machinery manufacturing. These billets are typically made from molten steel that is cast into a solid form and then further processed to shape and size. Due to their high strength, durability, and versatility, steel billets are ideal for constructing heavy-duty components and structures in construction machinery. They can be used to manufacture various parts such as chassis, frames, buckets, booms, and arms, among others. The use of steel billets ensures that construction machinery is capable of withstanding the demanding conditions and heavy loads commonly encountered in construction projects.

- Q: How are steel billets used in the production of structural sections?

- Steel billets are used in the production of structural sections by being heated and then passed through a series of rollers to form the desired shape, such as I-beams, angles, or channels. These sections are essential in construction and engineering projects as they provide strength, support, and stability to buildings and structures.

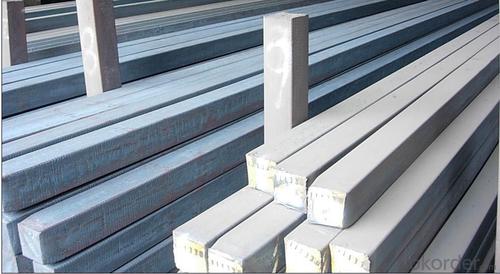

- Q: What are steel billets?

- Steel billets are semi-finished metal products that are rectangular in shape and usually have a square cross-section. They are produced through a process called casting or continuous casting, where liquid steel is poured into molds and allowed to cool and solidify. Once cooled, the billets are typically hot-rolled or forged to give them their final shape and dimensions. Steel billets serve as a raw material for the production of various steel products, such as bars, rods, wires, and structural sections. They are commonly used in the construction industry for structural purposes, as well as in the manufacturing of automotive parts, pipes, and machinery. The quality of steel billets is crucial, as it directly affects the quality and performance of the final steel products. Therefore, they undergo rigorous quality checks and testing to ensure they meet the required standards for strength, durability, and other mechanical properties. Overall, steel billets play a vital role in the steel industry as a primary raw material for the production of a wide range of steel products, making them an essential component in various sectors of the economy.

- Q: Can steel billets be used in the production of agricultural equipment?

- Steel billets have the potential to be utilized in the manufacturing process of agricultural equipment. These billets are essentially unfinished products that are typically formed through a continuous casting method. They can undergo further processing to take on various shapes and sizes, which makes them suitable for the production of agricultural machinery like plows, cultivators, harrows, seeders, and other similar farm equipment. The utilization of steel billets in agricultural machinery brings about numerous benefits. Steel is renowned for its robustness, longevity, and resistance to deterioration, making it ideal for heavy-duty applications within the agricultural sector. Moreover, steel is capable of withstanding harsh environmental conditions, ensuring that the machinery remains dependable and functional even in demanding farming environments. Furthermore, steel can be easily shaped and fabricated into different forms, allowing for the customization of agricultural equipment to meet specific requirements. Overall, incorporating steel billets in the manufacturing process of agricultural equipment enhances the efficiency, productivity, and longevity of farming operations.

- Q: What are the different types of steel billet defects?

- There are various types of steel billet defects, including surface defects like cracks, laps, and scars, as well as internal defects such as segregation, porosity, and inclusions.

- Q: What are the different surface defects in steel billets?

- Some common surface defects in steel billets include cracks, scars, pits, surface roughness, and scale.

- Q: How are steel billets used in the manufacturing of construction machinery?

- Steel billets are an essential component in the manufacturing of construction machinery. These billets are large, semi-finished steel products that are commonly used as raw material in the construction machinery industry. They are typically produced through a process called continuous casting, where molten steel is poured into a mold to form a solid billet. Once the steel billets are produced, they undergo various manufacturing processes to shape them into the desired components of construction machinery. This includes forging, rolling, and machining. Forging involves heating the billets to a high temperature and then shaping them through the application of pressure, resulting in the formation of various parts such as gears, shafts, and axles. Rolling is another commonly used method, where the billets are passed through a series of rolling mills to reduce their size and shape them into specific forms, such as plates, bars, or sheets. These rolled billets can be further processed to create components like chassis, frames, or structural beams for construction machinery. In addition to forging and rolling, machining processes are also employed to shape the steel billets into intricate parts with specific dimensions. This involves using cutting tools to remove excess material and create precise shapes and features, such as holes, threads, or grooves. Machining is crucial for producing components like engine parts, hydraulic cylinders, or gearboxes for construction machinery. Overall, steel billets serve as the starting point for the manufacturing of construction machinery, providing the necessary raw material that is then transformed through various processes into the required components. The strength, durability, and versatility of steel make it an ideal material for construction machinery, ensuring the final product can withstand heavy loads, harsh environments, and demanding applications.

- Q: How are steel billets rolled or forged into other shapes?

- Steel billets can be transformed into various shapes through a process called rolling or forging. Rolling involves passing the heated billet through a series of rollers that apply pressure to reshape the material. This process is often used to produce long and flat shapes such as sheets, plates, and bars. During rolling, the billet is first heated to a specific temperature to make it more malleable. It is then fed into the rolling mill, where a pair of rotating rollers exerts pressure on the billet to reduce its thickness and elongate it. The rollers can be smooth or grooved, depending on the desired shape of the final product. The billet is passed through the rollers multiple times, gradually reducing its thickness and lengthening it. This process can be repeated with different sets of rollers to achieve specific dimensions and cross-sectional shapes. The final product is then cooled and cut to the desired length. Forging, on the other hand, involves applying compressive forces to the heated billet to shape it into various forms. There are two main types of forging processes: open-die forging and closed-die forging. In open-die forging, the heated billet is placed between two flat dies, and a hammer or press applies pressure to deform the material. The billet is repeatedly struck or pressed until it takes the desired shape. This process is commonly used for producing large and complex shapes such as crankshafts, connecting rods, and turbine discs. Closed-die forging, also known as impression-die forging, involves using two or more dies with cavities that mirror the desired shape of the final product. The heated billet is placed between the dies, and pressure is applied to force the material into the cavities, filling them completely. This process is often used to produce smaller and more intricate shapes like automotive parts, hand tools, and fittings. Both rolling and forging processes require the billet to be heated to a specific temperature to make it more ductile and easier to shape. The choice between rolling and forging depends on factors such as the desired shape, size, and mechanical properties of the final product.

- Q: How do steel billets contribute to the overall vibration resistance of a structure?

- Steel billets contribute to the overall vibration resistance of a structure by providing a strong and rigid framework. The high strength and stiffness of steel billets help to absorb and distribute dynamic loads, reducing the amplitude and impact of vibrations. This structural stability minimizes the risk of fatigue and damage caused by vibrations, ensuring the long-term integrity and durability of the structure.

- Q: What is the typical elongation of a steel billet?

- The typical elongation of a steel billet can vary depending on several factors such as the specific grade of steel, the manufacturing process, and the intended application. However, in general, the elongation of a steel billet is typically around 20% to 30%. Elongation is a measure of a material's ability to deform or stretch before breaking. It is usually expressed as a percentage and is determined by conducting a tensile test on a sample of the material. During this test, the sample is subjected to gradually increasing tensile forces until it eventually fractures. The amount of elongation is measured by comparing the original length of the sample to its final length at the point of fracture. Steel is known for its high tensile strength, which means it can withstand significant forces without breaking. However, it also exhibits a certain degree of ductility, allowing it to elongate before reaching its breaking point. The typical elongation of a steel billet falls within the range mentioned above, indicating that it can stretch by 20% to 30% of its original length before fracturing. It's important to note that different grades of steel can have varying elongation properties. For example, higher carbon steels tend to have lower elongation values compared to low carbon or mild steels. Additionally, the manufacturing process can also affect the elongation of a steel billet. Processes such as hot rolling or cold drawing can modify the microstructure of the steel, thereby influencing its elongation characteristics. Ultimately, the specific elongation requirements for a steel billet will depend on the intended application. Certain industries, such as construction or automotive, may require steel with higher elongation values to ensure the material can withstand the stresses and strains it will encounter during use. Conversely, other applications may prioritize higher tensile strength over elongation.

Send your message to us

Prime quality prepainted galvanized steel 720mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords