Prime quality prepainted galvanized steel 700mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Specifications

Commodity Name: Prepainted Galvanized Steel Coil

Standard: AISI, ASTM, DIN, GB, JIS

Grade: TDC52D+Z

Thickness 0.13-8.0mm

Width:600mm-1350mm

Zinc Coating:275g/m2

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

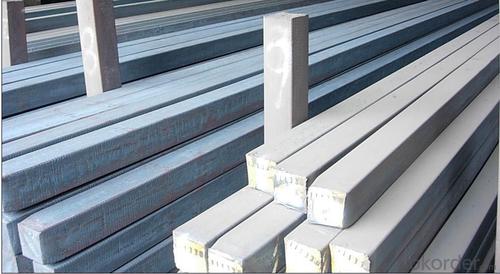

- Q: How are steel billets used in the manufacturing of valves and fittings?

- Valves and fittings rely on steel billets, an essential raw material, for their production. These billets are solid steel forms, cast into specific shapes and sizes. The manufacturing process starts by heating the steel billets to a high temperature and passing them through rolling mills to achieve the desired form. This process refines the grain structure, enhancing the steel's strength, ductility, and overall quality. After shaping, the billets undergo further processing and machining to create various valve and fitting components, including bodies, bonnets, stems, and other essential parts. Precise machining ensures accurate dimensions and smooth surfaces, enabling proper assembly and functioning. Steel billets also provide crucial strength and durability to valves and fittings, as they are made from high-quality steel. This ensures that the final products can withstand the harsh operating conditions, pressure, and temperature variations they may encounter. Moreover, steel billets offer versatility in manufacturing, allowing the production of different types of valves and fittings, such as gate valves, ball valves, butterfly valves, and pipe fittings. This flexibility enables manufacturers to meet diverse industry requirements. In summary, steel billets serve as the primary raw material in the production of valves and fittings. Shaping, processing, and machining these billets result in high-quality components that offer strength, durability, and precision in the final products.

- Q: How are steel billets used in the production of agricultural components?

- Steel billets are an essential raw material used in the production of various agricultural components. These billets serve as the starting point for the manufacturing process, where they are transformed into a wide range of agricultural components such as plows, harrows, tillers, cultivators, and seeders. The steel billets are first melted down and cast into a solid form, typically a rectangular or square shape, with a consistent cross-section. This solid piece of steel is then heated and rolled into the desired shape and size required for the specific agricultural component being produced. Once the billets have been rolled and shaped, they undergo further processes such as cutting, drilling, bending, and welding to form the final agricultural component. These components are designed to withstand the demanding conditions of the agricultural industry, including exposure to harsh weather, heavy loads, and frequent use. Steel billets offer several advantages in the production of agricultural components. Firstly, steel is a strong and durable material, providing the necessary strength and resilience required for agricultural machinery to operate effectively. Additionally, steel is highly resistant to corrosion, ensuring that the agricultural components can withstand exposure to moisture, fertilizers, and other chemicals commonly used in farming. Furthermore, steel billets can be easily customized and fabricated into different shapes and sizes, allowing for the production of a wide variety of agricultural components that cater to specific farming needs. The versatility of steel billets also enables manufacturers to create components with intricate designs and features, enhancing their functionality and performance. In conclusion, steel billets play a crucial role in the production of agricultural components. The versatility, strength, and durability of steel make it an ideal material for manufacturing machinery and equipment used in the agricultural industry. By starting with steel billets and transforming them through various manufacturing processes, agricultural components are created that can withstand the demanding conditions of farming and contribute to the efficiency and productivity of agricultural operations.

- Q: What is the chemical composition of a typical steel billet?

- The composition of a typical steel billet, which serves as a semi-finished material for various steel products, primarily consists of iron and carbon. However, the specific chemical composition can differ based on the grade and intended application of the steel billet. Alongside iron and carbon, different elements like manganese, silicon, sulfur, and phosphorus may also be present in varying quantities. These elements are incorporated to confer specific properties to the steel, such as increased strength, improved machinability, or enhanced corrosion resistance. To ensure the desired mechanical and chemical properties are attained, the exact composition of a steel billet is meticulously regulated during the manufacturing process.

- Q: Charcoal classification

- Hard charcoal. By hardwood such as Fagaceae Quercus, Castanopsis trees, secondary birch and etc..Broad-leaved charcoal. Charcoal made from a mixture of hard and soft hardwood.Pine charcoal. Carbon fired from pine or other needle wood. In addition to bamboo and bamboo charcoal burning with shells, stones (coconut shell, peach stone charcoal etc.) wood raw material firing. Charcoal collected from household stoves in the cell known as carbon. If the charcoal is crushed and mixed with proper adhesive, and then pressed, formed and roasted, the deposit is made. According to the burning process of silica and carbon black.

- Q: How do steel billets contribute to the energy industry?

- The energy industry heavily relies on steel billets, as they serve as the primary raw material for manufacturing various energy-related equipment and infrastructure. Steel billets, which are semi-finished steel products, find extensive use in the construction of power plants, oil and gas pipelines, wind turbines, and other energy infrastructure projects. A crucial application of steel billets in the energy industry lies in the production of power plant components. Boilers, turbines, and generators, which require high levels of strength, durability, and resistance to high temperatures and pressure, are manufactured using steel billets. By incorporating steel billets, power plant manufacturers ensure the reliability and longevity of their equipment, thereby contributing to the overall efficiency and stability of the energy generation process. Steel billets also play a vital role in the construction of oil and gas pipelines. These pipelines are essential for transporting oil, natural gas, and other energy resources from production sites to refineries and end-users. Steel billets are used to manufacture the large-diameter pipes that form the foundation of these pipelines. The strength, toughness, and corrosion resistance of steel billets guarantee the integrity and safety of the pipeline infrastructure, minimizing the risk of leaks or failures that could result in energy supply disruptions or environmental damage. Moreover, steel billets are indispensable in the production of wind turbines, which are rapidly emerging as a renewable energy source. The towers and foundations of wind turbines are primarily made of steel, and steel billets are employed in their manufacturing due to their exceptional strength and load-bearing capabilities. By utilizing steel billets, wind turbine manufacturers can construct tall and sturdy towers capable of supporting the rotor and ensuring the efficient conversion of wind energy into electricity. In conclusion, steel billets significantly contribute to the energy industry by enabling the construction of robust and reliable infrastructure. The strength, durability, and versatility of steel billets make them an ideal material for energy-related projects, promoting the efficient and sustainable generation, transportation, and utilization of energy resources.

- Q: Are steel billets used in the aerospace industry?

- Yes, steel billets are used in the aerospace industry. They are often used as raw materials for manufacturing various components and parts, such as engine components, landing gear, and structural supports. Steel billets offer excellent strength and durability, making them suitable for aerospace applications that require high-performance materials.

- Q: How are steel billets rolled into rails?

- Steel billets are rolled into rails through a process called hot rolling. This process involves several steps to transform the steel billets into the desired rail shape. Firstly, the steel billets are heated in a furnace to a temperature of around 1200°C. This high temperature makes the steel malleable and easier to shape. Once the billets reach the desired temperature, they are transferred to a rolling mill. In the rolling mill, the heated steel billets are passed through a series of rolling stands. These stands consist of pairs of large rolls that gradually reduce the thickness and shape of the billets. As the billets pass through each stand, the rolls exert immense pressure on the steel, causing it to elongate and take on the characteristics of a rail. As the billets progress through the rolling mill, they are gradually transformed into rails with the desired dimensions. The rolling process also imparts strength and durability to the rails, making them suitable for use in various applications, such as railway tracks. During the rolling process, water or oil is often used to cool the rolls and prevent them from overheating. This cooling also helps in maintaining the desired temperature of the steel billets as they pass through the rolling mill. Once the steel billets have been rolled into rails, they are cut to the desired lengths and subjected to further processing, such as straightening and heat treatment, to ensure the rails meet the required specifications. In summary, steel billets are rolled into rails through the hot rolling process. This involves heating the billets, passing them through a series of rolling stands, and gradually shaping them into rails with the desired dimensions. The resulting rails are then further processed and prepared for use in various applications.

- Q: How are steel billets manufactured?

- Steel billets are manufactured through a process called continuous casting, which is the most common method used in the steel industry. This process involves pouring molten steel into a water-cooled mold, where it solidifies and takes the shape of a rectangular or square cross-section. The molten steel is typically obtained from a steelmaking furnace, such as a basic oxygen furnace or an electric arc furnace. Before the casting process begins, the mold is preheated to prevent the molten steel from solidifying prematurely. Once the mold is ready, the molten steel is poured into it through a ladle or a tundish, which helps control the flow of the liquid steel and removes impurities. As the molten steel enters the mold, it starts to cool rapidly due to the water-cooled walls of the mold. This rapid cooling leads to the solidification of the outer layer of the steel, forming a solid shell. The cooling process continues as the steel moves through the length of the mold, with water being sprayed on it to accelerate solidification. Once the solidified steel reaches the end of the mold, it is cut into desired lengths using a cutting torch or a mechanical shear. These solidified steel pieces, known as billets, are then transferred to a cooling bed or a roller table, where they continue to cool and solidify further. After sufficient cooling, the billets are inspected for any surface defects or other irregularities. Depending on the quality requirements, the billets may undergo further processing, such as heat treatment or surface conditioning, to improve their mechanical properties and surface finish. Overall, the continuous casting process allows for the efficient and cost-effective production of steel billets, which serve as a crucial raw material for various downstream steel products, such as bars, rods, and wire rods.

- Q: What are the common grades of steel used for billets?

- The common grades of steel used for billets vary depending on the intended application and specific requirements. However, some of the most commonly used grades include: 1. Carbon Steel: Carbon steel billets are widely used due to their high strength, durability, and affordability. Grades such as AISI 1018, 1020, 1045, and 1060 are commonly used for general-purpose applications. 2. Alloy Steel: Alloy steel billets are blended with specific alloying elements to enhance their mechanical properties such as strength, toughness, and corrosion resistance. Grades like AISI 4140, 4340, and 8620 are commonly used for applications requiring higher strength, heat resistance, or wear resistance. 3. Stainless Steel: Stainless steel billets are chosen for their excellent corrosion resistance and aesthetic appeal. Grades such as 304, 316, and 420 are commonly used for various applications, including construction, automotive, and food processing industries. 4. Tool Steel: Tool steel billets are specifically designed to have high hardness, wear resistance, and toughness. Grades such as AISI O1, D2, and A2 are commonly used for manufacturing cutting tools, dies, and molds. It is important to note that the selection of the appropriate grade of steel depends on the specific requirements of the application, such as mechanical properties, corrosion resistance, and temperature resistance. Consulting with a metallurgist or an expert in the field can help determine the most suitable grade of steel for billet production.

- Q: What are the different types of steel billets?

- There are several different types of steel billets, each with its own unique characteristics and applications. Some of the most common types include: 1. Carbon Steel Billets: These are the most widely used type of steel billets and are made from iron and carbon. Carbon steel billets are known for their high strength and durability, making them suitable for a wide range of applications, including construction, automotive, and machinery manufacturing. 2. Alloy Steel Billets: These billets are made by adding various alloying elements to carbon steel, such as chromium, nickel, or manganese. Alloy steel billets offer enhanced properties such as increased strength, hardness, and corrosion resistance. They are often used in industries that require high-performance materials, such as aerospace, oil and gas, and power generation. 3. Stainless Steel Billets: Stainless steel billets are made with a high content of chromium, which provides excellent resistance to corrosion and oxidation. They are commonly used in applications where hygiene, durability, and aesthetic appearance are crucial, such as food processing, medical equipment, and architectural structures. 4. Tool Steel Billets: Tool steel billets are specially designed to have high hardness, wear resistance, and heat resistance. They are commonly used to make cutting tools, molds, and dies for various industries, including automotive, manufacturing, and construction. 5. Electrical Steel Billets: Electrical steel billets are made from low carbon steel with specific magnetic properties. They are used in the manufacturing of electrical equipment, such as transformers, motors, and generators, where low energy loss and high magnetic permeability are vital. 6. High-speed Steel Billets: High-speed steel billets are alloyed with elements like tungsten, molybdenum, and cobalt, which enable them to retain their hardness and strength at high temperatures. They are widely used to make cutting tools that need to withstand high-speed cutting operations, such as drills, milling cutters, and taps. These are just a few examples of the different types of steel billets available. The choice of steel billet depends on the specific requirements of the application, such as strength, durability, corrosion resistance, or special properties needed for particular industries.

Send your message to us

Prime quality prepainted galvanized steel 700mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords