Prime hot rolled steel square billet mill price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17145 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

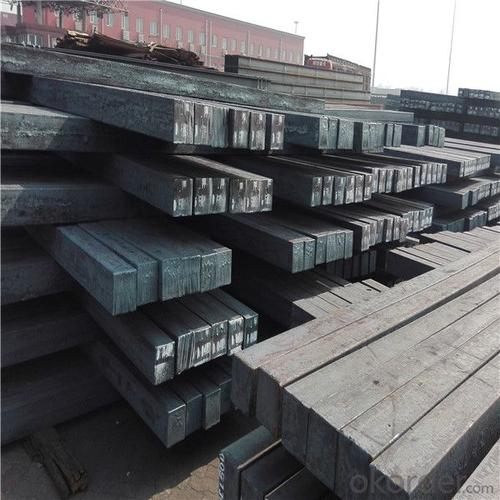

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel

billets are also known for their malleability and ductility, especially when exposed to varying temperatures

during shaping and molding.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

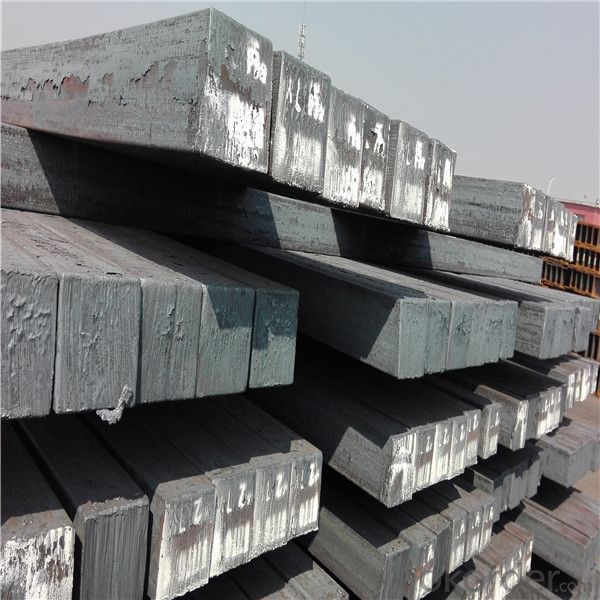

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: Can steel billets be used for making cutlery?

- Steel billets have the potential to be utilized in the creation of cutlery. These billets serve as the primary substance in the manufacturing of a variety of steel commodities, which encompass cutlery. Once heated, the billets are then transformed into desired forms, such as knives, forks, or spoons, through methods like forging or casting. The resultant steel cutlery possesses notable attributes such as strength, durability, and the ability to maintain a sharp edge. Nevertheless, it is important to recognize that the specific kind of steel employed and the manufacturing procedures substantially influence the quality and characteristics of the cutlery.

- Q: What are the main safety considerations when handling steel billets?

- The main safety considerations when handling steel billets include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Proper lifting techniques should be used to prevent strains and back injuries when moving heavy billets. Additionally, ensuring a well-organized and clutter-free work area, as well as proper storage and stacking of the billets, can help prevent accidents and injuries.

- Q: What are the common sizes and shapes of steel billets?

- To cater to the diverse needs of different industries, steel billets are typically manufactured in various sizes and shapes. The most common sizes range from 100mm to 200mm in width and 100mm to 300mm in height. However, it should be noted that these dimensions can vary based on the specific requirements of the end-user or the steel manufacturer. Regarding shapes, rectangular and square shapes are commonly produced. Rectangular billets have flat and smooth surfaces with four right angles, while square billets have equal sides with four right angles as well. These shapes are preferred because they facilitate easier handling, transportation, and further processing of the steel billets. Furthermore, steel billets can also be produced in non-traditional shapes such as round, hexagonal, or octagonal, depending on the intended application. These unique geometries are often utilized in specialized industries like automotive or aerospace manufacturing to meet specific design requirements. It is important to mention that the sizes and shapes of steel billets can vary across different regions and industries, as each may have their own specific standards and preferences. Therefore, manufacturers and end-users should communicate and align their requirements to ensure the production of steel billets that meet their respective needs.

- Q: What are the different types of steel billet cutting tools?

- There are several types of steel billet cutting tools, including circular saws, band saws, abrasive saws, and torches.

- Q: What are the advantages of using steel billets in the oil and gas industry?

- There are several advantages of using steel billets in the oil and gas industry. Firstly, steel billets offer exceptional strength and durability, making them suitable for withstanding extreme conditions and high-pressure environments commonly found in the industry. Secondly, steel billets can be easily shaped and machined into various components, allowing for customization and flexibility in designing equipment and structures. Additionally, steel billets have excellent resistance to corrosion, which is crucial in preventing damage caused by exposure to harsh chemicals and corrosive environments. Lastly, steel billets have a high melting point, making them suitable for applications that involve high temperatures, such as refining and processing operations in the oil and gas industry.

- Q: How can steel billets be customized for specific applications?

- Steel billets have the potential to be tailored to specific applications using a variety of techniques and processes. One commonly used method involves subjecting the billets to controlled heating and cooling cycles, known as heat treatment, in order to modify their mechanical properties. This can involve processes like annealing, quenching, tempering, or normalizing, which can help achieve desired levels of hardness, toughness, or ductility. Another way to customize steel billets is through alloying, which involves adding specific elements like chromium, nickel, or molybdenum to the steel composition. This enhances the properties of the billets to meet the requirements of different applications. For instance, adding chromium can improve corrosion resistance, while nickel can enhance strength and toughness. Moreover, the shape and size of steel billets can be customized. Depending on the intended use, billets can be cast into various shapes such as round, square, or rectangular, to better suit their purpose. Additionally, the dimensions of the billets can be adjusted to specific requirements, allowing for more efficient processing and minimizing material waste. Surface treatments can also be applied to steel billets to further customize them for specific applications. These treatments, including shot blasting, pickling, or coating, improve the surface finish, remove impurities, and provide protection against corrosion. Overall, the customization of steel billets for specific applications involves a combination of heat treatment, alloying, shaping, and surface treatments. Through these processes, the mechanical properties, composition, shape, and surface characteristics of the billets can be fine-tuned to meet the specific requirements of different industries and applications.

- Q: What are the key factors driving the demand for steel billets?

- The key factors driving the demand for steel billets include a growing global population and urbanization, which leads to increased infrastructure development and construction projects. Additionally, the demand is driven by the manufacturing sector's need for steel billets to produce various steel products, such as pipes, rods, and wires. Economic growth, industrialization, and increased investments in renewable energy and transportation sectors also contribute to the rising demand for steel billets.

- Q: How do steel billets contribute to the manufacturing of telecommunications equipment?

- Steel billets are an essential raw material in the manufacturing of telecommunications equipment. They are used to form various components such as frames, housings, brackets, and mounting structures. The strength, durability, and versatility of steel make it an ideal choice for these applications, providing the necessary support and protection for sensitive electronic components. Additionally, steel billets can be easily machined, welded, and coated, allowing for precise customization and finishing required in telecommunications equipment.

- Q: How do steel billets contribute to the overall weight reduction of a product?

- Steel billets contribute to the overall weight reduction of a product by allowing manufacturers to create lighter and more structurally efficient components. By using steel billets, which are smaller and more compact than traditional steel bars or plates, less material is needed to achieve the same strength and performance. This reduction in weight not only makes the product easier to handle and transport, but also improves its overall energy efficiency.

- Q: What are the different types of heat treatment processes used for steel billets?

- There are several different types of heat treatment processes used for steel billets. Some commonly used methods include annealing, normalizing, quenching and tempering, and case hardening. Each process has its own purpose and is used to achieve specific properties in the steel billets.

Send your message to us

Prime hot rolled steel square billet mill price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17145 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords