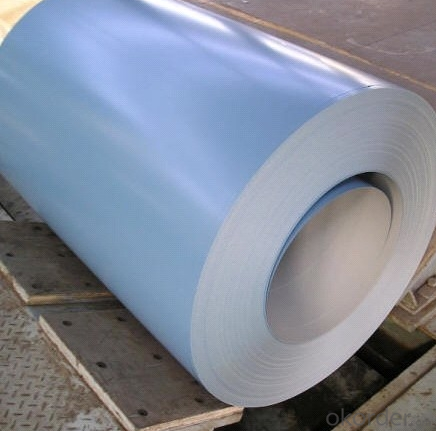

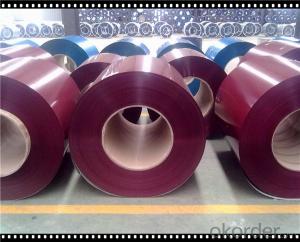

PrepaintedHot-Dip and Galvanized Steel Coil CNBM

- Ref Price:

-

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195/235/345,ASTM A36,SS400,SPHC | Thickness: | 1.5-25mm |

| Technique: | Hot Rolled | Application: | Container Plate | Special Use: | High-strength Steel Plate |

| Width: | 300-1500mm | Length: | coil | Surface Treatment: | black/bright/galvanized,etc |

| Authentication: | ISO9001-2008,SGS.BV,etc |

|

|

|

|

Packaging & Delivery

| Packaging Details: | tandard seaworthy export package or as customers required |

| Delivery Detail: | within 25 days after confirming the order |

Sepcification and Feature

| Minerals & metallurgy |

Thickness | 1.8-20mm |

Width | 914-2000mm |

Coil weight | about 25 tons |

Material Grade | A36,Q195,Q235,SS400,SPHC,ST37/52 |

Technique | hot rolled |

Standard | AISI,ASTM,DIN,GB,JIS |

|

|

What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: what is the differance between ceramic and stainless steel headers and 4-2-1 and 4-1 and which are better for racing and should i get ceramic or stainless steel headers???? for a 98 civic

- This Site Might Help You. RE: ceramic vs stainless steel headers HELP!!!!!!!!!!!!!! for a 98 civic? what is the differance between ceramic and stainless steel headers and 4-2-1 and 4-1 and which are better for racing and should i get ceramic or stainless steel headers?? for a 98 civic

- Q: I should have known, but magnets don't stick to stainless steel, so now I'm at a loss, I can't display my photos on the fridge. any ideas?

- Hi There, I am re-doing my kitchen and since my all stainless steel refrigerator will no longer be used to hold all my memos and pictures, I will hang a magnetic board in one area of my kitchen which will hold all the photos and memos that I had before and it would look very neat this way.. bably much neater than when they were on the fridge. Also, you can get a multiphoto frame for the photos and hang this on the wall. Then, the magnetic board can be just for notes and clips with invitations, etc. Hope this helps.

- Q: How many inches of steel can an AK47 using 7.62x39mm rounds penetrate through?

- It can't go through inches. It can go through up to 1/4 of an inch of plate steel but not much more. An M-16 can go through it as well and has less powder behind it but the 7.62X39 is a fat round and it takes a little more to get it through.

- Q: What are the different methods of laminating steel coils?

- There exist multiple techniques for laminating steel coils, each possessing its own advantages and applications. The prominent techniques encompass hot rolling, cold rolling, and continuous annealing.

Hot rolling involves heating the steel above its recrystallization temperature and subsequently passing it through a sequence of rollers to generate thin sheets or coils. This method is frequently employed for the mass production of steel with a uniform thickness and surface finish. Structural applications such as construction and automotive manufacturing commonly utilize hot rolled steel coils.

In contrast, cold rolling entails passing the steel coil through a set of rollers at room temperature. This process not only reduces the thickness of the steel but also enhances its surface finish and mechanical properties. Industries requiring high precision and quality, such as appliance manufacturing, electrical equipment, and automotive components, typically employ cold rolled steel coils.

Continuous annealing represents an alternative approach to laminating steel coils. It involves heating the steel coil to a specific temperature and gradually cooling it in a controlled environment. This procedure aids in alleviating internal stresses and enhancing the mechanical properties of the steel, such as strength and ductility. Continuous annealing is frequently utilized to produce high-quality steel coils for applications necessitating superior surface finish and formability, like automotive body panels and household appliances.

Additional less prevalent methods of laminating steel coils comprise electro-galvanizing and hot-dip galvanizing. Electro-galvanizing encompasses coating the steel with a zinc layer through an electroplating process, while hot-dip galvanizing entails immersing the steel coil in molten zinc. These techniques primarily serve corrosion protection purposes and are commonly employed in the construction industry, particularly for outdoor structures and infrastructure.

To summarize, the various techniques for laminating steel coils encompass hot rolling, cold rolling, continuous annealing, electro-galvanizing, and hot-dip galvanizing. Each approach offers distinct advantages and is selected based on the specific requirements of the application.

- Q: How do steel coil manufacturers ensure timely delivery?

- Steel coil manufacturers ensure timely delivery by implementing efficient production and supply chain management systems. They closely monitor the production process, maintain a well-planned inventory, and coordinate with logistics partners for streamlined transportation. Additionally, they prioritize effective communication with customers to understand their delivery requirements and provide regular updates on the progress and estimated delivery dates.

- Q: What are the common coil diameter and weight combinations available for steel coils?

- The common coil diameter and weight combinations available for steel coils vary depending on the specific requirements and industry standards. However, there are some commonly used combinations that are widely available in the market.

In terms of coil diameter, the most common sizes range from 24 inches (610 mm) to 72 inches (1829 mm). These diameters are typically used for various applications in industries such as automotive, construction, and manufacturing.

Regarding coil weight, the range can vary significantly depending on the type and thickness of the steel being coiled. For hot-rolled coils, the weight typically ranges from 5 to 30 metric tons. Cold-rolled coils usually have weights between 2 to 20 metric tons. Coils with larger weights are commonly used for heavy-duty applications, while lighter coils are preferred for more delicate or precise applications.

It is important to note that these are just general guidelines, and the actual coil diameter and weight combinations can be customized based on the specific needs of the customer. Different manufacturers and suppliers may offer a wide range of options to accommodate various industry requirements. Therefore, it's always advisable to consult with the specific supplier to determine the available coil diameter and weight combinations that best suit your specific application.

- Q: I'm going to buy a guitar for beginners and i wondered what strings are better steel or nylon?

- Musical type speaks volumes on the subject of this problem. Folks that want high quantity shall be unhappy with unamplified nylon string guitars. From my point of view, the elemental difference between steel and nylon is that this: steel strings ring and nylon strings resonate. The volume produced via steel is quite often a lot bigger than nylon however, to my mind-set, the sound resonance produced with the aid of the wooden of your guitar is essentially masked by steel strings. In case you have a decently made guitar (generally, around a thousand dollars and up), the sound interaction between the wooden and the strings in a nylon guitar is magical across the whole frequency range. With a steel string guitar, the sound produced via the vibrating string overpowers the timber resonance at all but low frequencies. In my view, i'll take a nylon string guitar any day for the sensitivity won from the interplay between timber and vibrating string.

- Q: Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials.

- Q: and what type of metal is steel?

- From the steel store. ;) Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.14% by weight (C:110–10Fe), depending on grade. Carbon is the most cost-effective alloying material for iron, but various other alloying elements are used such as manganese, chromium, vanadium, and tungsten.

- Q: For example, (and this is weird) if I were wearing a steel collar and I needed some way to remove it, with limited supplies.Force is difficult because it would be around my neck.Chemical cominations are great- but they have to use VERY common products. And I'm not sure what to use.Other ideas?

- There are plenty of ways to damage/weaken steel... shear or tensile force, fatigue, temperature, corrosion, grinding, etc... there are even dozens of ways to do each of the things I just listed. But in the case you suggested, with the steel being very close to skin... a simple pair of bolt cutters would probably be the easiest.