Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

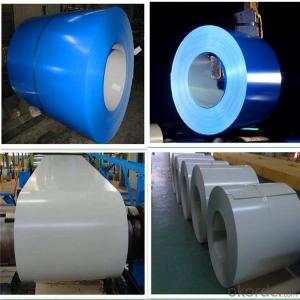

Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

Description of Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel perform in terms of electrical resistivity?

- Special steel typically has relatively high electrical resistivity compared to other materials. This means that it does not conduct electricity as efficiently as materials with lower resistivity.

- Q: How does special steel contribute to the telecommunications equipment industry?

- The telecommunications equipment industry greatly relies on special steel to support its complex infrastructure and advanced technologies. Special steel plays a critical role by providing the necessary strength, durability, and reliability. An important aspect of special steel is its ability to withstand extreme weather conditions and environmental factors. Telecommunications equipment, such as transmission towers, antennas, and satellites, often face harsh elements like strong winds, heavy rain, and earthquakes. Special steel, with its high tensile strength and resistance to corrosion, ensures the stability and longevity of the infrastructure, minimizing the risk of damage or failure. Additionally, special steel is used in the production of various components for telecommunications equipment. Connectors, cables, and electronic enclosures, for example, require materials with excellent electrical conductivity and heat dissipation properties. Special steel alloys, including stainless steel or nickel-based alloys, are utilized to meet these requirements, ensuring efficient signal transmission and preventing overheating issues. Furthermore, special steel is crucial for manufacturing high-quality tools and equipment used in the installation, maintenance, and repair of telecommunications networks. Specialized steel alloys, such as tool steel, provide exceptional hardness, toughness, and wear resistance, enabling the production of reliable and long-lasting tools. These tools are essential for professionals in the telecommunications industry as they allow for efficient and accurate installation and maintenance, ensuring uninterrupted connectivity for end-users. Moreover, as the telecommunications industry continues to advance, special steel is vital in supporting the deployment of advanced technologies like 5G networks and fiber-optic systems. These technologies require specialized components, such as waveguides, reflectors, and amplifiers, often made from special steel alloys to ensure optimal performance and durability. By providing the necessary materials for these cutting-edge technologies, special steel contributes to the expansion and enhancement of telecommunications infrastructure worldwide. In conclusion, special steel is indispensable to the telecommunications equipment industry due to its strength, durability, and reliability, which are crucial for infrastructure, components, tools, and advanced technologies. Its unique properties enable the industry to provide efficient and uninterrupted communication services to individuals and businesses globally.

- Q: What are the different types of special steel?

- There are several types of special steel, including stainless steel, tool steel, high-speed steel, carbon steel, alloy steel, and maraging steel. These different types of special steel are designed to possess specific properties and characteristics that make them suitable for various applications across industries such as construction, automotive, aerospace, and manufacturing.

- Q: How does special steel contribute to the electronics aftermarket industry?

- Special steel plays a crucial role in the electronics aftermarket industry by offering superior properties like high strength, hardness, and corrosion resistance, making it an ideal material for manufacturing various electronic components. From connectors and terminals to springs and contacts, special steel ensures the durability and reliability of these parts, thereby enhancing the overall performance and longevity of electronic devices. Its unique properties also enable miniaturization of components, allowing for the development of smaller and more advanced electronic products.

- Q: How does special steel perform in surface hardening applications?

- Special steel performs exceptionally well in surface hardening applications. Due to its unique composition and properties, it can undergo various surface hardening processes like carburizing or nitriding, resulting in enhanced surface hardness, wear resistance, and overall durability. This makes special steel an ideal choice for applications where high strength and improved surface properties are required, such as in automotive components, cutting tools, or industrial machinery.

- Q: How does special steel contribute to the transportation equipment industry?

- Special steel plays a crucial role in the transportation equipment industry by providing high strength, durability, and resistance to wear and corrosion. It allows for the construction of lighter yet stronger components, leading to improved fuel efficiency, increased payload capacity, and enhanced safety in vehicles. Additionally, special steel enables the production of precision parts and components, ensuring the reliability and performance of transportation equipment.

- Q: What are the different types of high-strength steel?

- There are several different types of high-strength steel, including advanced high-strength steels (AHSS), ultra-high-strength steels (UHSS), and microalloyed steels. AHSS are specifically designed to provide improved strength and formability, making them suitable for automotive applications. UHSS have even higher strength levels than AHSS and are often used in applications where weight reduction and crashworthiness are critical, such as in the aerospace industry. Microalloyed steels are a type of high-strength steel that use small amounts of alloying elements to achieve increased strength and toughness.

- Q: How does special steel contribute to the manufacturing of turbine blades?

- Special steel plays a crucial role in the manufacturing of turbine blades as it offers exceptional mechanical properties, such as high strength, corrosion resistance, and heat resistance. These properties enable turbine blades to withstand extreme operating conditions, including high temperatures and pressures. Additionally, the specific composition of special steel allows for precise shaping and intricate designs, which optimize the aerodynamic efficiency of the blades. Overall, special steel enables the production of turbine blades that are durable, efficient, and capable of withstanding the demanding conditions of power generation.

- Q: What are the common challenges in forging special steel?

- In order to achieve desired outcomes, manufacturers and engineers must tackle several common challenges when forging special steel. One of these challenges involves maintaining precise temperature control throughout the forging process. Special steels often have specific heat treatment requirements, and any deviation from the recommended temperature range can have a negative impact on the final properties of the material. Therefore, it is crucial to achieve and sustain the appropriate temperature to ensure desired mechanical properties such as strength, hardness, and toughness. Another challenge is controlling the cooling rate during quenching. Quenching is a critical step in the heat treatment process that helps to achieve the desired hardness and strength in special steels. However, rapid cooling can lead to the formation of undesired microstructures or even cracking. Therefore, it is essential to carefully manage the cooling rate to avoid these issues and ensure optimal material properties. Additionally, shaping special steels through forging can be challenging due to their high strength and hardness. These materials are often more difficult to deform compared to regular steels, requiring higher forging pressures and specialized equipment. The resistance to deformation can result in increased wear on the forging dies, necessitating frequent maintenance and replacement. Furthermore, special steels may contain alloying elements that can affect their forgeability. Some alloying elements can promote grain growth, which can reduce the mechanical properties of the material. It is crucial to find the right balance of alloying elements and optimize the forging process parameters to achieve the desired microstructure and properties in the final product. Lastly, ensuring consistency and repeatability in the forging process can be challenging. Special steels are often produced in smaller quantities or for specific applications, making it important to maintain process control and quality assurance. Proper documentation, monitoring, and quality control measures need to be implemented to ensure that the forged special steel meets the desired specifications and performance requirements. Overall, addressing these challenges through proper process control and optimization is essential to obtain high-quality special steel products with the desired mechanical properties and performance characteristics.

- Q: Can special steel be used in the manufacturing of sports equipment?

- Yes, special steel can be used in the manufacturing of sports equipment. Special steel refers to a type of steel that has been specifically designed and engineered to possess certain characteristics and properties that make it suitable for various specialized applications. These characteristics can include high strength, durability, resistance to corrosion and wear, and the ability to withstand extreme conditions. In the manufacturing of sports equipment, special steel can be used in a variety of ways. For example, it can be utilized to create the shafts of golf clubs or tennis rackets, where its high strength and stiffness are crucial for optimal performance. Special steel can also be used in the construction of sports equipment such as bicycles, where its lightweight yet strong properties are highly desirable. Additionally, special steel can be employed in the manufacturing of sports equipment accessories, such as hooks, buckles, or fasteners. These components often require high tensile strength and corrosion resistance, and special steel can provide these properties, ensuring the longevity and reliability of the equipment. In summary, special steel can indeed be used in the manufacturing of sports equipment, thanks to its unique properties that enhance performance, durability, and overall quality.

Send your message to us

Prepainted Steel PPGI Steel Coil Suppliers Sheet in Coil Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords