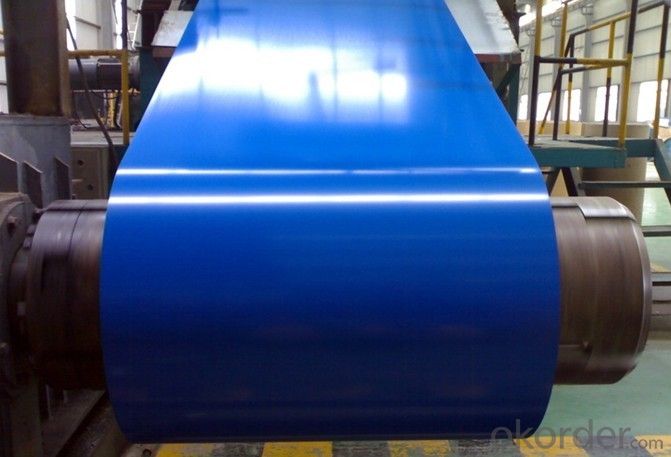

Stable quality ppgi printed prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | PPGI printed prepainted steel coil, Prepainted galvanized steel coil, Stable quality ppgi printed prepainted steel coil |

Advantage | 1.Exquisite technology 2.Advanced production lines 3.High and stable quality products 4.Reputable enterprise 5.Competitive price 6.Good aftersale service |

Thickness | 0.13mm-0.7mm |

Width | 914mm,1000mm,1200mm,1219mm,1220mm,1250mm You also can customize other wide product, like 600mm, 225mm,125m, ect. By the way, the width less than 600mm, it will be no drawback |

Zinc coating | 40-100gsm |

Color | sea blue, white grey, crimson, RAL9002, RAL9006, RAL9016, and other RAL code color |

Application | general commercial using, for deep drawing, for structural components, etc |

Package | 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized |

Product information

Width:600-1500mm,Thickness:0.18-2.00mm

Steel grade:CGCC,SGCC,TDC51D,TDC52D,DX51D

Painting thickness:Front:15-20um,primer:5-7um,Back side:5-7um.

Base material:galvanized steel coil or galvalume steel coil

Zinc coating:60-200g/m2 for galvanized steel coil.60-150g/m2 for galvalume steel coil.

Type of painting:PE,PVDF,SMF or according to the requirements.

Standard:GB/T 12754-2006,ASTM A755M,JIS G3312,EN10169/DIN

Technical:cold rolled

Surface treatment:color coated

Coil ID:508mm/610mm

Package:export standard package or as requirements

Certification:BV/SGS/ISO

Samples:allowed for free.color can be blue,red,white.

Terms:

a)Trade terms:FOB/CFR/CIF

b)Payment terms:T/T,L/C and more favorable terms for old customers.

c)Provid capacity:10000 tons per month

d)MOQ:25 tons or negotiation.

e)Delivery time:10-20 days for 25 tons

f)loading port:Tianjin Port.

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves unwinding the steel coil, passing it through a set of rotating circular blades called slitters, and then rewinding the resulting narrower strips onto separate spools.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers to provide strength, durability, and structural integrity. These coils are processed and shaped into the necessary components, such as walls, floors, and roofs, which are then assembled to create a sturdy container. The steel coils also allow for easy transportation and stacking of the containers, ensuring safe and efficient shipping of goods worldwide.

- Q: How are steel coils priced and traded in the market?

- Steel coils are priced and traded in the market based on several factors. The primary factor is the current demand and supply dynamics of the steel industry. When the demand for steel coils is high, the prices tend to increase, and vice versa. Another important factor in pricing steel coils is the cost of raw materials, such as iron ore and coal, which are essential for steel production. Fluctuations in the prices of these materials can directly impact the pricing of steel coils. Additionally, the quality and specifications of the steel coils also play a significant role in determining their price. Higher-quality coils with specific characteristics, such as strength, corrosion resistance, or surface finish, may command a premium price in the market. The trading of steel coils is primarily done through various platforms, including physical exchanges, futures contracts, and over-the-counter (OTC) markets. Physical exchanges allow buyers and sellers to trade steel coils by exchanging physical deliveries. Futures contracts, on the other hand, enable traders to buy or sell steel coils at a predetermined price and future date, providing a way to hedge against price fluctuations. The OTC market is another avenue for trading steel coils, where buyers and sellers negotiate and agree on prices directly without going through a formal exchange. This provides flexibility and customization in trading, allowing for specific requirements to be met. Overall, the pricing and trading of steel coils in the market are influenced by demand and supply dynamics, raw material costs, quality specifications, and trading platforms. It is a complex process that requires careful consideration of various factors to determine fair prices and facilitate efficient trading.

- Q: Like 49ers. Pittsburgh have long history of steel industry?

- Yes, short and simple

- Q: What are the common standards and specifications for steel coils?

- In the industry, there are various widely recognized and utilized standards and specifications for steel coils. Some notable ones include: 1. ASTM A36/A36M: This specification is concerned with carbon structural steel shapes, plates, and bars of structural quality. It is intended for use in constructions that involve riveting, bolting, or welding. 2. ASTM A572/A572M: This specification focuses on high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars. It is applicable for constructions involving bolting, riveting, or welding. 3. ASTM A653/A653M: This specification pertains to steel sheet that is zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) through the hot-dip process. 4. ASTM A1011/A1011M: This specification covers various types of steel sheet and strip in coils, such as hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high strength. 5. JIS G3302: This Japanese Industrial Standard specifies the requirements for hot-dip zinc-coated steel sheet, also known as galvanized steel sheet, and strip. 6. EN 10111: This European standard outlines the requirements for continuously hot-rolled low carbon steel sheet and strip that are suitable for cold forming. 7. ISO 3575: This International Organization for Standardization standard lays down the requirements for hot-dip zinc-coated and zinc-iron alloy-coated steel sheet and strip. These are just a few instances of the prevalent standards and specifications employed for steel coils. It is crucial to note that different industries and applications may have specific demands, thus consulting the relevant standards and specifications for the particular application is always advisable.

- Q: Okay, I have looked all ovcer the net and it says diamonds are stronger, but why? I mean, why is diamonds used for the top equiptment rather than steel?

- diamonds are not so much 'stronger' but they are harder than steel. they are harder because of the symmetry of their crystalline structure. Steel can be made harder by helping it's crystalline structure become more symmetrical, but it's not going to have the perfect structure that diamonds do....it's just impossible due to the chemistry of steel. Many industrial drill bits or abrasives use tiny diamonds for the cutting edge, because they are harder and therefore can withstand more abuse before eroding away. coring bedrock is one common application. However, diamonds do have their weaknesses, and by the right person they can be cut along planes with relative ease. diamonds are not malleable or ductile, so making equipment out of them is just not in the cards, not to mention how much money it would cost to do so....and you can't weld diamonds together to make a long piece of diamond, what you get out of the earth is what you get....or they can make diamonds, but still, we can't create diamonds that are multiple feet long!!

- Q: How are steel coils coated for color and aesthetics?

- Steel coils can be coated for color and aesthetics through a process called coil coating. This process involves applying a layer of paint or coating material to the surface of the steel coil to enhance its appearance and provide protection against corrosion. The coil coating process typically begins with a thorough cleaning and pre-treatment of the steel surface. This step ensures that the surface is free from any contaminants and provides a suitable base for the coating to adhere to. The pre-treatment process may involve cleaning, degreasing, and chemical treatment to enhance the adhesion and durability of the coating. Once the surface is prepped, the coil is then fed through a continuous coating line. In this line, the coating material, which is usually a liquid paint, is applied to both sides of the steel coil using various methods such as roll coating, spray coating, or electrostatic coating. The coating material is carefully selected to provide the desired color, texture, and durability. After the coating is applied, the coil goes through a curing process, where it is heated to allow the coating material to dry and bond to the steel surface. This ensures a strong and durable finish that can withstand exposure to various environmental conditions. Coil coating technology also allows for additional treatments to enhance the aesthetics of the steel coil. For example, the coil can undergo a process called embossing, where a pattern is embossed onto the surface, giving it a textured or three-dimensional appearance. Additionally, other decorative techniques like printing, laminating, or adding metallic effects can be employed to achieve specific aesthetic effects. Overall, the coil coating process not only adds color and aesthetics to steel coils but also provides a protective layer that increases their lifespan and resistance to corrosion. This makes them suitable for a wide range of applications, including roofing, automotive parts, appliances, and construction materials.

- Q: What are the potential dangers of handling steel coils?

- The potential dangers of handling steel coils include the risk of injuries due to their heavy weight and sharp edges, the possibility of crushing accidents or being struck by falling coils, and the potential for back or muscle strain from manually lifting or moving the coils.

- Q: Having a new kitchen and would like to know the pros and cons of stainless steel as opposed to white appliances. I can only think of finger marks on the SS, which I believe are difficult to remove. Anyone had both that they could advise please?

- I have Stainless Steel and YES it shows finger prints etc, Since there are no children around it's easier to keep clean, but one word of caution when using commercial SS cleaners, if the spray gets onto the floor it's almost impossible to get off and makes it slippery as ice. I'd use newspaper before using a SS cleaner,, I've had both and would opt for WHITE in any case. So easy to maintain, Now, they do make a Faux SS, which is very nice., and don't show any markings at all, our Son has one and with 3 kids in the house constantly using the Fridge it's been great, you might want to look into that..

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are used in the production of storage tanks as they provide the necessary strength and durability required for containment and storage of various substances. These coils are rolled into cylindrical shapes and welded together to form the tank's body, ensuring a tight and secure structure. Additionally, the steel coils can be coated or treated to provide corrosion resistance, further enhancing the tank's longevity and suitability for storing liquids or gases.

Send your message to us

Stable quality ppgi printed prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords