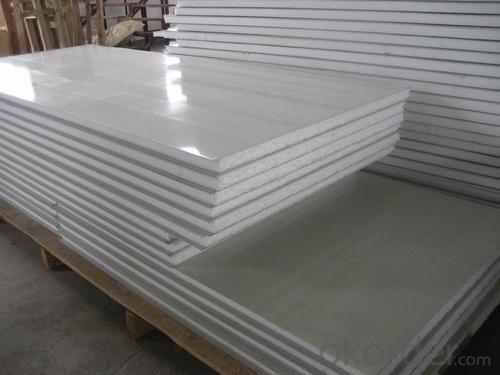

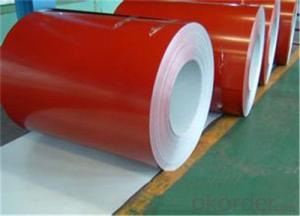

Prepainted Steel Coil PPGI GI of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.12 - 2.00 mm | Place of Origin: | Tianjin China (Mainland) |

| Brand Name: | cnbm | Model Number: | DX51D ,SGCC,SGCH | Type: | Steel Coil |

| Technique: | Hot Rolled | Surface Treatment: | Galvanized | Application: | Construction |

| Special Use: | High-strength Steel Plate | Width: | 702mm- 1250mm | Length: | as your requirement |

| Certification: | BV,SGS,TUV |

Packaging & Delivery

| Packaging Detail: | standard sea-worthy package or as customers' requirement |

| Delivery Detail: | generally 10-25 days or as customers' quantity |

Specifications

1.reasonable price

2.reliable quality

3.fast shipment

4.huge production capacity

5.BV,SGS and TUV certificates

The details:

| Base Material | Hot Dipped Galvanized Steel |

| Grade | ASTM,DX51D,SGCC,CGCC and CGCH. |

| Thickness | 0.12~2.0mm |

| Coil width | 600~1250mm |

| Coil ID | 508- 610mm |

| Coil weight | 3~7 tons |

| Zinc coating | 40~275 g/m2 |

| Painting | Top and bottom :15~25 microns |

| Back :5~8 microns | |

| Color | RAL system as per customers requirement |

| Package | Export seaworthy packing |

| MOQ | 25 tons |

- Q: Can steel sheets be used in architectural or decorative applications?

- Yes, steel sheets can definitely be used in architectural or decorative applications. Steel is a versatile and durable material that offers numerous benefits for both structural and aesthetic purposes. In architectural applications, steel sheets can be used for roofing, wall cladding, and structural framing, providing strength, stability, and resistance to harsh weather conditions. Additionally, steel sheets can be fabricated into various shapes, sizes, and finishes, allowing architects and designers to create unique and visually appealing structures. In decorative applications, steel sheets can be used for interior and exterior design elements such as decorative panels, screens, railings, and sculptures. The ability to customize steel sheets with various patterns, textures, and colors makes them a popular choice for enhancing the visual appeal of buildings and spaces. Overall, steel sheets are a versatile material that can be utilized in a wide range of architectural and decorative applications, offering both functionality and aesthetics.

- Q: How can the offset film affixed to the cold-rolled steel sheet be removed?

- On the hard surface of the self-adhesive mark, we can use non greasy wash water on the surface of the object, and then gently wipe with soft cloth; with industrial alcohol or gasoline can also remove these traces. If these stickers are found on the skin, they can also be removed with lemon juice.

- Q: What is hot and cold rolled steel plate? How to distinguish? What high hardness? Which will produce noisy eye?

- By definition, ingot or billet is difficult to deform under normal temperature, easy processing, generally heated to 1100 to 1250 DEG C for rolling, the rolling process of hot rolled steel rolling. Most are called hot method. But because the surface under high temperature steel is easy to produce iron oxide, the surface roughness of hot rolled steel, size fluctuation so large, smooth surface, precise size, good mechanical properties of the hot rolled steel, semi-finished or finished products and raw materials for the production of cold rolling method. Under normal temperature, generally understood as cold, from the metal science point of view, the boundaries of cold rolling and hot rolling should be differentiated by the recrystallization temperature is lower than rolling recrystallization. The temperature is higher than the recrystallization temperature of cold rolling, rolling for hot rolled steel. The recrystallization temperature is 450 ~ 600 degrees. The difference: the simple point that 1, cold rolled plate surface has a certain gloss hand feels smooth, Similar to that used for drinking water is very common, such as hot rolled.2 steel cup without pickling treatment, is on the market and many are similar to ordinary steel plate surface, rusty surface is red, the surface of the rusty purple black (iron oxide).The performance advantages of cold rolled plate and strip is: 1, high precision, cold rolled strip thickness not more than 0.01~0.03mm.2, thinner, cold rolled steel strip rolling thickness 0.001mm hot rolling; now the thin can reach 0.78mm.3, the surface quality is more superior, cold rolled steel plate can even produce mirror surface; and the surface of hot rolled plate there are defects such as pitting of iron oxide,.4, cold rolled plate can be adjusted according to the running properties such as tensile strength and technological properties such as stamping performance requirements of the user.

- Q: What are the properties of steel sheets?

- Steel sheets possess several desirable properties that make them highly sought after in numerous industries. Firstly, their exceptional strength and durability are well-known. They have the ability to withstand heavy loads and exhibit a high resistance to impact and deformation. Consequently, they are considered ideal for applications where strength is paramount, such as in the construction, automotive, and aerospace sectors. Another noteworthy characteristic of steel sheets is their excellent corrosion resistance. Typically, steel is coated with a thin layer of zinc or other protective materials to prevent rusting and corrosion. This protective coating enhances the longevity of steel sheets, enabling their use in outdoor or humid environments without the risk of degradation. Steel sheets are also renowned for their versatility. They can be easily bent, shaped, and welded, making them suitable for various fabrication processes. This adaptability empowers manufacturers to effortlessly create intricate structures and components, rendering steel sheets a popular choice in architectural and industrial designs. Furthermore, steel sheets exhibit excellent thermal conductivity. This property enables them to efficiently transfer and distribute heat, making them well-suited for applications that require temperature regulation, such as in heating systems or electrical appliances. Lastly, steel sheets are highly recyclable, rendering them an environmentally-friendly option. Steel is one of the most recycled materials worldwide, and the recycling process does not compromise its properties or quality. This sustainability factor establishes steel sheets as the preferred choice for those seeking eco-friendly materials. In conclusion, the properties of steel sheets encompass strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability. These qualities make steel sheets a reliable and versatile material for a wide range of industries and applications.

- Q: What is the process of applying soundproofing materials to steel sheets?

- The process of applying soundproofing materials to steel sheets typically involves cleaning the surface of the steel sheets to remove any dirt or debris. Then, an adhesive or bonding agent is applied to the steel sheets, followed by the soundproofing material, such as acoustic foam or mass-loaded vinyl. The soundproofing material is pressed firmly onto the adhesive to ensure proper adhesion. Depending on the specific application, additional steps such as sealing the edges or using mechanical fasteners may be included.

- Q: Can steel sheets be used for structural beams?

- No, steel sheets cannot be used for structural beams. Structural beams require specific shapes and profiles to provide adequate strength and support for buildings and other structures. Steel sheets, on the other hand, are flat and thin and are typically used for cladding, roofing, or other non-structural purposes.

- Q: Can steel sheets be bent or formed?

- Yes, steel sheets can be bent or formed through various processes such as cold forming, hot forming, or using specialized machinery like press brakes or rolling machines.

- Q: Are the steel sheets easy to transport and handle?

- Yes, steel sheets are relatively easy to transport and handle. They are typically compact and lightweight, making them convenient to move around. Additionally, their flat and rigid nature allows for easy stacking and loading onto transportation vehicles. However, larger and heavier steel sheets may require specialized equipment and machinery for safe handling and transportation.

- Q: Can steel sheets be used for food processing equipment?

- Yes, steel sheets can be used for food processing equipment. Stainless steel is a popular choice for food processing equipment due to its durability, corrosion resistance, and ease of cleaning. It is non-reactive with food and does not impart any unwanted flavors or odors. Steel sheets can be formed into various shapes and sizes, making them suitable for different types of food processing equipment such as mixers, conveyors, tanks, and cutting blades. Additionally, stainless steel is also resistant to high temperatures, making it ideal for applications that involve heat. Overall, steel sheets are a reliable and hygienic material choice for food processing equipment.

- Q: Can steel sheets be welded?

- Yes, steel sheets can be welded.

Send your message to us

Prepainted Steel Coil PPGI GI of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords