Prepainted Galvanized Rolled Steel Sheet from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

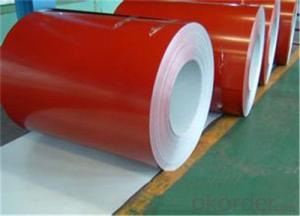

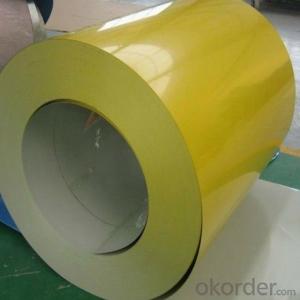

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

Thickness:0.15mm-1.2mm

Width:600mm-1250mm

Coil ID:508mm/610mm

Base Metal: GI/GL.

Zinc Coating:30-275 G/M2

Paint Coating: Top 30; Back 5-7. Or up to Buyer’s Option.

With Protection Film or Without Protection Film.

Spangle: Regular Spangle, Small Spangle, Zero Spangle.

Coil Weight:3-5MT or Customized Weight.

Delivery:15-25 days

MOQ:25MT

Color: RAL Color Series or Customized Colors.

Temper: Commercial Quality G 350; Structural Quality: G550; Full Hard.

Charactics of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products

- Q: I bought a steel pendant on eBay, but it turned out to be too shiny.I've read on a couple forums that if I leave it soaked in urine for 2 days, it will get duller.Now, if it really does get duller, will the pendant get rusty afterwards?So is the shiny surface the only thing that prevents it from rusting?Any simple, non-urine ideas on how to make it duller are welcome too.Thanks!

- Stainless steel will rust under proper conditions. I live on a boat on salt water, trust me. If the urine works it won't be prone to rusting any more than before. It's not the shine that inhibits rusting with stainless steel, it the % of carbon in the steel, compared to regular steel. IF the urine works it's because it is acidic (a mild acid). Wash it with a small brush and some baking soda to neutralize the acid when your done. A much stronger acid would be swimming pool acid. (Muriatic acid) but be careful you might test a spot with a Q tip on the back. If you try Muriatic acid it would take seconds.Then wash in baking soda water to remove all acid.. SS

- Q: What is the weight of a steel coil?

- The weight of a steel coil can vary depending on its size and thickness. Generally, a steel coil can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: What are the common surface defects found in steel coils?

- Steel coils can have several surface defects commonly found. One prevalent defect is rust or corrosion, which happens when moisture contacts the steel surface and causes oxidation and rust formation. Another defect is scratches or abrasions, occurring during coil handling or transportation. These can vary from small surface scratches to deeper gouges that affect the steel's structural integrity. Surface roughness or unevenness is also possible due to improper rolling or cooling processes during manufacturing, resulting in inconsistent surface texture that affects appearance and performance. Scale is another defect, forming an oxide layer during manufacturing, giving the steel a rough and uneven look. Finally, oil or grease stains may occur during manufacturing or handling, impacting paint or coating adhesion. These common surface defects impact steel quality, appearance, and performance, often requiring cleaning, grinding, or recoating as remedial actions.

- Q: I expect that I will be questioned about my knowledge in methoding for steel castings, in a interview. I dont know about it. Can someone explain me in simple language and give me some links, like how I can explain methoding for steel castings.....key points...help please...so that i will pass the interview as if I have experience in methoding....thanks

- It is very difficult to define Methoding of Steel castings by one sentence. Actually it encompasses the total casting process. Normally it would mean a) Pattern design i.e. what type of pattern it would be- wooden, metallic, split or full, loose or fitted on a match plate or any other, how will be the parting line. b) Design of the gating system. c) Design of risering i.e. numbers, size and location of risers. d) Design of molding process i.e. sand system to be used, mold box size. But to do justice to the above mentioned activities, you need to consider other parameters of the casting process such as chemical composition, solidification characteristics, pouring temperature, pouring time, knock out time etc. As I said Methoding of Steel castings means designing of the total casting process from inception to final product.

- Q: How are steel coils used in the production of steel beams?

- The production of steel beams requires the use of steel coils, which are a vital element in the process. Typically, these coils are created by hot rolling steel strips in a continuous manner. Subsequently, the coils are transported to a steel beam manufacturing facility for further processing. To begin with, the steel coils are unraveled and flattened in order to achieve a flat surface. This step ensures that the dimensions of the beam are uniform and enhances the overall quality. The uncoiling process involves passing the coil through a series of rollers, which gradually unwind the steel strip. Once the steel strip has been unraveled, it is then divided into specific lengths based on the desired size of the steel beams. Generally, this cutting process is executed using automated machinery, which guarantees precision and accuracy. Following that, the cut steel strips are shaped to match the desired profile of the steel beams. This is accomplished through a technique known as roll forming, in which the steel strip is passed through a sequence of rollers that progressively bend and shape it to the required form. The roll forming process enables the creation of various types of steel beams, including I-beams, H-beams, and U-beams, depending on the design and structural requirements. After the roll forming process, the steel beams undergo additional finishing operations, such as straightening, welding, and surface treatment. Straightening ensures that the beams are perfectly aligned and devoid of any deformities. Welding is performed to connect different sections of the beams, ensuring their structural integrity. Finally, the beams are subjected to surface treatment, typically involving methods such as shot blasting or painting, to safeguard against corrosion and enhance their aesthetic appearance. In conclusion, steel coils play a critical role in the production of steel beams, serving as the essential raw material that undergoes uncoiling, cutting, shaping, and further processing. These high-quality steel beams find extensive application in diverse construction projects, encompassing buildings, bridges, and industrial structures, thereby cementing their status as an indispensable component within the construction industry.

- Q: Went to top gun range in Houston, Tx. Guy there said no steel bullets..Anyone know why? Think i can shoot them anywhere else? Perhaps an outdoor gun range? The are monarch FMJ 9mm steel rounds..Thanks!

- Top Gun Range Houston

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

- Q: Can steel coils be stretched?

- No, steel coils cannot be stretched as they are already tightly wound and have limited flexibility.

- Q: How are steel coils used in the production of HVAC equipment?

- Steel coils are used in the production of HVAC equipment primarily for their heat transfer capabilities. These coils, made of high-quality steel, are essential components in the heat exchangers of HVAC systems. They help facilitate the transfer of heat between the refrigerant and the surrounding air, allowing for efficient heating or cooling. The steel coils are typically designed with fins or tubes to increase the surface area and enhance heat transfer efficiency, ensuring optimal performance and energy efficiency in HVAC units.

- Q: Can steel coils be used in the production of automotive parts?

- Yes, steel coils can be used in the production of automotive parts. Steel coils are commonly used in the manufacturing of various automotive components such as body panels, chassis parts, springs, and engine components due to their strength, durability, and formability. The coils are processed and shaped into the desired automotive parts using various techniques such as cutting, stamping, welding, and forming.

Send your message to us

Prepainted Galvanized Rolled Steel Sheet from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords