Prepainted rolled Steel Coil for construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

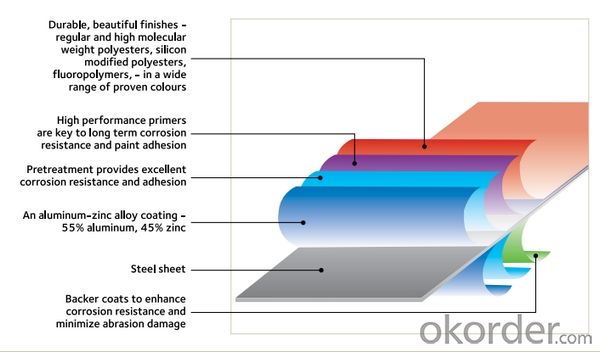

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does coil slitting work?

- Coil slitting is a process used to cut large coils of material, such as metal or plastic, into narrower strips. It involves feeding the coil through a set of rotating circular blades that make longitudinal cuts along the length of the coil. The blades are set at predetermined widths to achieve the desired strip thickness. The process is usually automated and ensures efficient and precise cutting, resulting in multiple narrower coils that can be used for various industrial applications.

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- Kera...time to crank up the brain in gear....molten refers to what state of matter? Solid, Liquid, Gas, Plasma? Ding-Ding-Ding....liquid. Solid to liquid is the melting point.

- Q: how come when i put steel legs in lowest price in grand exchange no one buys them i got 101 steel legs in there and there at lowest price and they have been there for 3 days

- Becuase you should sell something else.

- Q: Can steel coils be deep-drawn?

- Yes, steel coils can be deep-drawn. Deep drawing is a metal forming process in which a sheet or coil of material, such as steel, is stretched and pulled into a die to create a deep, hollow shape. Steel coils are often used in industries such as automotive, appliance, and manufacturing, where deep-drawn components are required for various applications.

- Q: doesnt steel rust?

- Stainless steel is regular steel that has had nickel added in the manufacturing process. Because of the nickel it prevents rust.

- Q: Cast steel welding

- Normal okorder /.. Mild steel and cast steel produces a very long stream of brilliant sparks, with some forking. CI produces much shorter, dull reddish sparks and the volume of sparks is much less. many highly branched or intermittent sparks will be seen.

- Q: I'm pretty sure that this topic has been beaten to death by now. But, I still can't get a definite answer. With stainless steel, you get better corrosion resistance, and you will hold and edge longer. With carbon steel, you will hold a sharper edge, and you could forge a knife blade longer than 2 ft without breakage. I'm personally a fan of stainless steel ( the 440 grade stuff ), just because it seems to hold up to use and abuse better in the long run. HOWEVER, I have NEVER had a factory made knife break on me. I don't think that they would try to sell you a knife that didn't do what it was meant to do, at least to a reasonable degree. (I work for a living, and can't afford a custom $600 knife.) What do you think? Is this a pointless topic? Will there ever be a winner?

- I hate stainless steel! I hate shiny blades also! When I was a kid knifes were awesome! You could actually sharpen them! :) If we bought a new knife we would take an orange and slice it and leave the juice on the blade to purposefully darken it. If you had a shiny blade that looked like stainless you were not cool. :) I think most anyone who had an old knife from back in the 70's or before would agree that these new stainless knives are crap. I have not seen anything perform close to the old blades in stainless. Today I bought a case CV Sod Buster hoping it will perform like the old knives. What reading I have done the Chrome Vanadium is supposed to be like the old steel. I sure hope it is. Now to find some fruit to get rid of this annoying shiny blade! :)

- Q: How are steel coils used in the production of electrical enclosures?

- Steel coils are used in the production of electrical enclosures to provide structural strength and durability. The coils are typically cut and bent into specific shapes to form the body and panels of the enclosure. This helps to protect the electrical components inside from external elements and ensure safe operation.

- Q: What is the lifespan of a steel coil?

- The lifespan of a steel coil can vary depending on various factors such as the quality of the steel, the conditions it is exposed to, and how it is properly maintained. On average, a well-maintained steel coil can last anywhere from 10 to 30 years.

- Q: Why can't you use a lead shot only choke with steel shot or a steel shot only choke with lead shot? I have used a lead only choke with steel shot and my shotgun shot fine and there was no damage to the choke.

- The reasoning behind lead shot only is that those chokes (usually) have a very tight constriction. It can cause severe and dangerous pressure spikes when a charge of steel shot (almost impossible to compress compared to lead) gets slammed through them. Another reason could be that the tubes are either very soft steel or very thin and steel shot will damage them quickly. I personally haven't seen any steel shot ONLY tubes before just ones marked for lead and/or steel or ok for steel shot.

Send your message to us

Prepainted rolled Steel Coil for construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords