All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

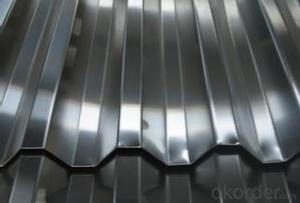

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does cold-rolled steel support the development of advanced transportation systems, including electric vehicles?

Cold-rolled steel is crucial in the development of advanced transportation systems, particularly electric vehicles, due to its enhanced properties. This type of steel undergoes a process that increases its strength, durability, and precision, making it ideal for various components in electric vehicles. Cold-rolled steel is commonly used in the manufacturing of battery casings, chassis, body panels, and other structural parts. It provides excellent formability, allowing for intricate designs, lightweight construction, and improved energy efficiency. Additionally, the high strength-to-weight ratio of cold-rolled steel ensures the safety and structural integrity of electric vehicles, supporting their overall development and advancement in the transportation industry.

Can you describe the role of temper rolling and skin-pass mills in cold-rolled steel production?

Temper rolling and skin-pass mills are crucial processes in the production of cold-rolled steel. Temper rolling involves passing the steel through a series of rolling mills to improve its mechanical properties, including its hardness, strength, and surface finish. It helps to adjust the steel's grain structure and reduce internal stresses, resulting in improved flatness and shape control.

On the other hand, skin-pass mills are used to provide the steel with a final surface quality. This process involves a light cold rolling operation that smoothens the steel's surface, enhances its appearance, and improves its surface texture. It also improves the steel's flatness and removes any defects or imperfections that may have occurred during the earlier stages of production.

Overall, temper rolling and skin-pass mills play vital roles in cold-rolled steel production, ensuring the desired mechanical properties, surface quality, and dimensional accuracy of the final product.

How does cold-rolled steel impact the quality of materials used in the automotive interior?

Cold-rolled steel improves the quality of materials used in the automotive interior by enhancing their strength, durability, and overall performance. Due to the cold-rolling process, the steel becomes more rigid, making it less susceptible to deformation or damage. This increased strength allows for the creation of lighter yet stronger components, leading to improved safety and fuel efficiency in vehicles. Additionally, the smooth and uniform surface finish achieved through cold rolling ensures a high-quality appearance and facilitates better adhesion of paints or coatings, enhancing the aesthetic appeal of automotive interiors.

How does cold-rolled steel behave under various stress conditions?

Cold-rolled steel generally exhibits enhanced strength and hardness compared to hot-rolled steel, making it more resistant to deformation and cracking under stress conditions. It also tends to have improved dimensional accuracy and surface finish, offering better performance in applications that require precise tolerances. However, due to its increased hardness, cold-rolled steel can be more brittle and susceptible to stress-related failures, such as fractures, if subjected to excessive or sudden stress.

Wholesale Cold Rolled Steel from supplier in Palau

Whether you are in need of Cold Rolled Steel coils, sheets, or other related products, we have a wide selection to meet your specific requirements. Our team of experts is dedicated to providing you with prompt and accurate quotations, ensuring that you receive the best possible pricing for your Cold Rolled Steel needs.

In addition to our sales and quotation services, we also offer technical support to assist you in selecting the right Cold Rolled Steel products for your projects. Our knowledgeable staff can provide guidance on material specifications, grades, and applications, helping you make informed decisions.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement solutions for Cold Rolled Steel in Palau, ensuring that you have access to high-quality products at competitive prices.

Furthermore, our years of experience operating in the Palau market have given us valuable insights into the local industry and customer needs. We understand the unique challenges and requirements of working in Palau, and we are well-equipped to navigate these to deliver exceptional support for your projects.

At our company, we pride ourselves on our commitment to customer satisfaction. We strive to provide excellent service, timely deliveries, and reliable support to ensure that your Cold Rolled Steel requirements are met with the utmost professionalism and efficiency.

Contact us today to discuss your Cold Rolled Steel needs in Palau, and let us provide you with the comprehensive sales, quotation, and technical support services that you deserve.

In addition to our sales and quotation services, we also offer technical support to assist you in selecting the right Cold Rolled Steel products for your projects. Our knowledgeable staff can provide guidance on material specifications, grades, and applications, helping you make informed decisions.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This enables us to offer comprehensive procurement solutions for Cold Rolled Steel in Palau, ensuring that you have access to high-quality products at competitive prices.

Furthermore, our years of experience operating in the Palau market have given us valuable insights into the local industry and customer needs. We understand the unique challenges and requirements of working in Palau, and we are well-equipped to navigate these to deliver exceptional support for your projects.

At our company, we pride ourselves on our commitment to customer satisfaction. We strive to provide excellent service, timely deliveries, and reliable support to ensure that your Cold Rolled Steel requirements are met with the utmost professionalism and efficiency.

Contact us today to discuss your Cold Rolled Steel needs in Palau, and let us provide you with the comprehensive sales, quotation, and technical support services that you deserve.