All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

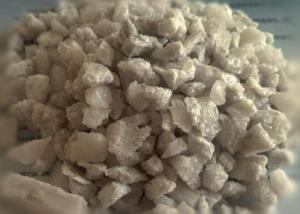

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractories maintain their strength at elevated temperatures?

Refractories maintain their strength at elevated temperatures due to their unique composition and structure. These materials are designed to have a high melting point and low thermal conductivity, which allows them to withstand extreme heat without significant degradation. Additionally, refractories have a dense and tightly packed structure that prevents the diffusion of heat and enables them to retain their mechanical properties even under high temperature conditions.

What are the different types of silica fume used in refractory applications?

There are primarily two types of silica fume used in refractory applications: undensified silica fume and densified silica fume. Undensified silica fume is a powdery material with a high surface area, while densified silica fume is agglomerated and has a lower surface area. Both types of silica fume can improve the properties of refractory materials, such as strength, durability, and resistance to high temperatures.

What are the refractory raw materials used in lining walking beam furnaces?

The refractory raw materials commonly used in lining walking beam furnaces include high alumina bricks, fire clay bricks, silica bricks, and magnesia bricks. These materials are chosen for their high temperature resistance, mechanical strength, and ability to withstand thermal shock and chemical corrosion.

Wholesale Raw Materials For Refractory from supplier in Palau

Whether you are in need of high-quality refractory materials such as alumina, magnesia, silica, or any other raw material, we have you covered. Our team of experts will assist you with product selection, ensuring that you have the right materials for your specific requirements.

In addition to supplying raw materials, we also offer exceptional sales and quotation services. Our dedicated sales team will work closely with you to understand your needs and provide competitive pricing for your projects. With our strong industry connections and network, we can source materials from renowned manufacturers, ensuring the highest quality and reliability.

Technical support is another key aspect of our services. Our experienced engineers and technicians are available to provide technical guidance and assistance throughout your project. Whether you need advice on material selection, processing techniques, or troubleshooting, we are here to help.

As a subsidiary of CNBM, a Fortune Global 500 company, we are backed by the resources and expertise of a leading global supplier. This enables us to provide comprehensive procurement services, including logistics management, quality control, and after-sales support.

Choose us as your supplier of raw materials for refractory products in Palau, and benefit from our extensive product range, market knowledge, and exceptional customer service. Contact us today to discuss your requirements and let us help you achieve success in your projects.

In addition to supplying raw materials, we also offer exceptional sales and quotation services. Our dedicated sales team will work closely with you to understand your needs and provide competitive pricing for your projects. With our strong industry connections and network, we can source materials from renowned manufacturers, ensuring the highest quality and reliability.

Technical support is another key aspect of our services. Our experienced engineers and technicians are available to provide technical guidance and assistance throughout your project. Whether you need advice on material selection, processing techniques, or troubleshooting, we are here to help.

As a subsidiary of CNBM, a Fortune Global 500 company, we are backed by the resources and expertise of a leading global supplier. This enables us to provide comprehensive procurement services, including logistics management, quality control, and after-sales support.

Choose us as your supplier of raw materials for refractory products in Palau, and benefit from our extensive product range, market knowledge, and exceptional customer service. Contact us today to discuss your requirements and let us help you achieve success in your projects.

Hot Search

- Monolithic Refractories in Slovakia

- Ceramic Fiber Products in Guyana

- Refractory Bricks in Azerbaijan

- Raw Materials For Refractory in Ukraine

- Refractory Bricks in Honduras

- Monolithic Refractories in Venezuela

- Raw Materials For Refractory in Greece

- Refractory Bricks in Mexico

- Raw Materials For Refractory in Norway

- Ceramic Fiber Products in Colombia