All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

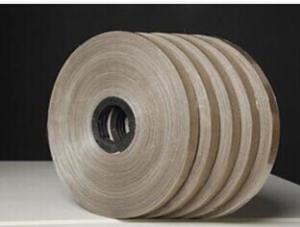

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How is sillimanite used in refractory materials?

Sillimanite is used in refractory materials due to its excellent heat resistance and high melting point. It serves as a key ingredient in the production of refractory bricks, castables, and other refractory products used in high-temperature applications. Its unique crystal structure and chemical composition allow it to withstand extreme temperatures and thermal shocks, making it ideal for lining furnaces, kilns, and other industrial equipment where heat retention and insulation are crucial.

What are the properties of perlite-based refractory materials?

Perlite-based refractory materials have several properties that make them ideal for various applications. Firstly, they have excellent thermal insulation properties, which allow them to withstand high temperatures without significant heat transfer. This makes them suitable for use in furnaces, kilns, and other high-temperature industrial processes.

Secondly, perlite-based refractory materials have low thermal conductivity, meaning they do not easily conduct heat. This property helps to reduce energy loss and improve overall energy efficiency in applications where insulation is required.

Additionally, perlite-based refractory materials are lightweight and have a low density, making them easy to handle and install. They also have good resistance to thermal shock and chemical corrosion, ensuring their durability and longevity in harsh operating conditions.

Lastly, perlite-based refractory materials are non-combustible and have low toxicity, making them safe for use in various industries, including the production of food, pharmaceuticals, and chemicals.

Overall, perlite-based refractory materials offer excellent insulation, high-temperature resistance, durability, and safety, making them a preferred choice in many industrial applications.

What are the refractory raw materials used in lining tunnel kilns?

The refractory raw materials commonly used in lining tunnel kilns include fireclay, high-alumina, and silica. These materials possess excellent thermal stability and resistance to high temperatures, making them ideal for withstanding the extreme conditions inside tunnel kilns.

Wholesale Raw Materials For Refractory from supplier in Norway

Whether you are in need of high-quality refractory raw materials for steel production, cement manufacturing, or other industrial applications, our team is dedicated to providing you with the best solutions. We understand the unique challenges and requirements of the Norway market and can offer tailored recommendations to ensure optimal performance and efficiency.

Our sales team is knowledgeable about the latest industry trends and can assist you in selecting the most suitable raw materials for your specific needs. We can provide you with detailed product information, technical data sheets, and samples to help you make informed decisions. Additionally, our experienced technical support team is available to answer any questions and provide guidance throughout the procurement process.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers worldwide. This enables us to offer competitive pricing and ensure a reliable supply chain. We work closely with our partners to maintain high-quality standards and adhere to strict quality control procedures.

At our core, we prioritize customer satisfaction and aim to build long-term relationships based on trust and mutual success. We understand the importance of timely deliveries and strive to provide efficient logistics solutions to meet your project timelines. Our dedicated customer service team is always available to address any concerns or issues you may have, ensuring a smooth and hassle-free experience.

Contact us today to discuss your refractory raw material needs in Norway, and let us help you find the best solutions for your projects.

Our sales team is knowledgeable about the latest industry trends and can assist you in selecting the most suitable raw materials for your specific needs. We can provide you with detailed product information, technical data sheets, and samples to help you make informed decisions. Additionally, our experienced technical support team is available to answer any questions and provide guidance throughout the procurement process.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers worldwide. This enables us to offer competitive pricing and ensure a reliable supply chain. We work closely with our partners to maintain high-quality standards and adhere to strict quality control procedures.

At our core, we prioritize customer satisfaction and aim to build long-term relationships based on trust and mutual success. We understand the importance of timely deliveries and strive to provide efficient logistics solutions to meet your project timelines. Our dedicated customer service team is always available to address any concerns or issues you may have, ensuring a smooth and hassle-free experience.

Contact us today to discuss your refractory raw material needs in Norway, and let us help you find the best solutions for your projects.

Hot Search

- Monolithic Refractories in Mongolia

- Ceramic Fiber Products in Paraguay

- Refractory Bricks in Palau

- Raw Materials For Refractory in Lithuania

- Raw Materials For Refractory in Singapore

- Monolithic Refractories in Nicaragua

- Ceramic Fiber Products in Brunei

- Refractory Bricks in Greece

- Raw Materials For Refractory in Argentina

- Raw Materials For Refractory in Angola