All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

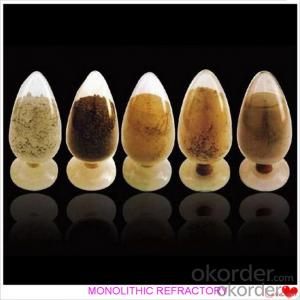

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do monolithic refractories perform in gasification applications?

Monolithic refractories perform well in gasification applications due to their excellent thermal stability and resistance to high temperatures and corrosive environments. They can withstand the severe conditions of gasification processes, including high temperatures, thermal cycling, and chemical reactions with gases and ashes. Additionally, monolithic refractories offer flexibility in installation, repair, and maintenance, making them suitable for various gasification systems.

How do monolithic refractories contribute to improving product quality in industrial processes?

Monolithic refractories play a crucial role in improving product quality in industrial processes by providing superior thermal insulation, chemical resistance, and mechanical strength. These refractories are designed to withstand high temperatures and harsh chemical environments, ensuring the stability and integrity of industrial furnaces, kilns, and reactors. By maintaining consistent and controlled temperatures, monolithic refractories prevent thermal variations that can negatively impact the quality of products being manufactured. Additionally, their excellent resistance to corrosive substances minimizes the risk of contamination, ensuring a clean and pure end product. Moreover, the mechanical strength of monolithic refractories enhances equipment reliability, reducing downtime and improving overall productivity. Ultimately, the use of monolithic refractories in industrial processes leads to enhanced product quality, increased operational efficiency, and cost-effectiveness.

How can the performance of monolithic refractories be optimized?

The performance of monolithic refractories can be optimized by carefully selecting the appropriate refractory material based on the specific application requirements, ensuring proper installation techniques, conducting regular inspections and maintenance, and monitoring and controlling the operating conditions such as temperature, thermal cycling, and chemical exposure. Additionally, using advanced refractory bonding systems and incorporating additives or coatings can further enhance their performance and extend their service life.

What are the key factors to consider when selecting monolithic refractories for a specific application?

When selecting monolithic refractories for a specific application, key factors to consider include the temperature range, chemical composition of the material being processed, mechanical stresses, thermal shock resistance, abrasion resistance, and the specific requirements of the application such as shape and size.

What are the key factors affecting the permeability of monolithic refractories?

The key factors affecting the permeability of monolithic refractories include the porosity and pore size distribution of the material, the presence of any cracks or defects, the temperature and pressure conditions, the type and amount of binder used, and the composition of the refractory material itself.

Wholesale Monolithic Refractories from supplier in Mongolia

Our team of experts is dedicated to understanding your specific needs and providing tailored solutions for your projects. We offer competitive pricing, reliable delivery, and exceptional customer service to ensure your satisfaction.

Whether you require Monolithic Refractories for high-temperature applications, furnace lining, or any other industrial use, we have a wide range of products to meet your requirements. Our products are manufactured using the highest quality materials and adhere to strict industry standards, ensuring durability and performance.

In addition to supplying Monolithic Refractories, we also provide comprehensive technical support services. Our team of experienced professionals can assist you with product selection, installation guidance, and troubleshooting. We understand the unique challenges and requirements of the Mongolian market and can offer valuable insights to help you achieve optimal results.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of technological advancements in the industry and offer innovative solutions to our customers.

We are committed to building long-term relationships with our clients and strive to exceed their expectations. Contact us today to learn more about our Monolithic Refractories products and services in Mongolia. We look forward to serving you and contributing to the success of your projects.

Whether you require Monolithic Refractories for high-temperature applications, furnace lining, or any other industrial use, we have a wide range of products to meet your requirements. Our products are manufactured using the highest quality materials and adhere to strict industry standards, ensuring durability and performance.

In addition to supplying Monolithic Refractories, we also provide comprehensive technical support services. Our team of experienced professionals can assist you with product selection, installation guidance, and troubleshooting. We understand the unique challenges and requirements of the Mongolian market and can offer valuable insights to help you achieve optimal results.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of technological advancements in the industry and offer innovative solutions to our customers.

We are committed to building long-term relationships with our clients and strive to exceed their expectations. Contact us today to learn more about our Monolithic Refractories products and services in Mongolia. We look forward to serving you and contributing to the success of your projects.

Hot Search

- Monolithic Refractories in Somalia

- Ceramic Fiber Products in Zimbabwe

- Refractory Bricks in Mauritius

- Raw Materials For Refractory in Bulgaria

- Raw Materials For Refractory in Brunei

- Raw Materials For Refractory in Netherlands

- Monolithic Refractories in Seychelles

- Ceramic Fiber Products in Samoa

- Refractory Bricks in Argentina

- Monolithic Refractories in Barbados