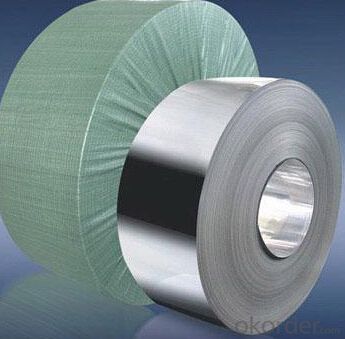

Prepainted Hot Dipped Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description.

Export Markets:Global

Additional Info.

Packing:Seaworthy

Origin:China

HS Code:72104900

Production Capacity:10000tons Per Month

Product Description

We are specialized in types of hot dipped galvanized, galvalume, prepainted steel products, corrugated steel sheet, etc.

Poduce Name: Prepainted Hot Dipped Steel Coil

Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

Grade: Q195 - Q235 and 08AL, SPCC, SPCD, SPCE, 08.10.15, SGCC (DX51D+Z) SGCD(DX52D+Z) etc.

Surface treatment: Chromated, unoiled/oiled, bright finished, spangle, fingerprint resistance.

Surface protection: PE, PVDF, SMP, HDP, etc.

Thickness: 0.20mm-2.0mm

Width: 1000mm, 1200mm, 1250mm, 1500mm, or according to your request.

Zinc coating: 80g-275GSM

Coil weight: 3-27 tons

Paint: Polyester silicon modified polyester, PVC sol, polyvinylidene chloride

Colour: RAL, or other series.

Application:

Architectural applications: Outdoor construction: Roof, the roof structure, balcony panels, water downpipe, window frames, gates, garage doors, roller shutter doors, kiosks, shutters, guard room, shower enclosure, refrigerated trucks and so on.

Indoor applications: Door, partitions, door frames, housing, light steel structure, sliding doors, screens, ceilings, bathroom interior, the elevator built, the elevator vestibule and so on.

Electrical Appliances: Refrigerators, frozen food display cabinets, washing machines, electric ovens, vending machines, air conditioners, copiers, switchgear, instrument cabinets, electric fans, vacuum cleaners and so on.

Transport: Car ceiling, backplane, hoardings, interior trim panels, car shell, trunk panels, car dashboard, console shell, tram, train ceiling, partitions, wall, door, ships separated Swatchesdoors, furniture board, flooring, container, etc.

Sheet metal processing and furniture applications: Ventilation and heating stoves, water heaters, shell, counters, shelves, signs, wardrobe, desk, bedside cabinets, chairs, lockers, file cabinets, bookshelves.

Exact Rate As Per Your Request.

| Color coated similar grades comparison table | |||||

| JISG 3312-1994 | |||||

| Q/BQB 440-2003 | |||||

| TDC51D(TSt01,TSt02,TSt03) | CGCC | ||||

| TDC52D | CGCD1 | ||||

| TDC53D | - | ||||

| TS280GD(TStE28) | CGC400 | ||||

| TS350GD(TStE34) | CGC440 | ||||

| TS550GD | CGC570 | ||||

| TSECC ,TBLCE | - | ||||

| TSECD ,TBLDE | - | ||||

| TSECE ,TBUSDE | - | ||||

| Q/BQB 445-2004 | AS 2728-1997a(AS 1397-2001) | JISG 3322-1998 | |||

| TDC51D+AZ | (G2+AZ) | CGLCC | |||

| TDC52D+AZ | (G3+AZ) | CGLCD | |||

| TS250GD+AZ | (G250+AZ) | - | |||

| TS300GS+AZ | (G300+AZ) | - | |||

| TS350GD+AZ | (G350+AZ) | CGLC490 | |||

| TS550GD+AZ | (G550+AZ) | CGLC570 | |||

| The coating surface structure classification | |||||

| classification | item | code | |||

| application | Building Exterior | JW | |||

| Building inside | JN | ||||

| Steel window | GC | ||||

| Household electrical appliances | JD | ||||

| funiture | JJ | ||||

| others | QT | ||||

| Coated surface state | Coating plate | TC | |||

| Embossing plate | YA | ||||

| Printing plate | YI | ||||

| Paint types | polyester | PE | |||

| Silicone modified polyester | SMP | ||||

| Poly vinylidene fluoride | PVDF | ||||

| Substrate types | Galvanized sheet | DX | |||

| Hot galvanized plate | Finishing zinc flower | ||||

| Spangle | |||||

| Coating structure | Upper surface | First coating | |||

| two coating | First coating | ||||

| two coating | two coating | ||||

| Supplier standards and grades | |||||

| The Grades and use of color coated sheet | Grades, standards and types of substrate | ||||

| Grades | applications | Grades | standards | type | |

| TDC51D | General use | DC51D+Z | Q/BQB 420 | Hot galvanized plate | |

| TDC52D | Stamping | DC52D+Z | |||

| TDC53D | deep Stamping | DC53D+Z | |||

| TS280GD | Structure | S280GD+Z | |||

| TS350GD | Structure | S350GD+Z | |||

| TS550GD | Structure | S550GD+Z | |||

| TSECC | General use | SECC | Q/BQB 430 | Galvanized sheet | |

| TSECD | Stamping | SECD | |||

| TSECE | deep Stamping | SECE | |||

| TBLCE | General use | BLCE+Z | |||

| TBLDE | Stamping | BLDE+Z | |||

| TBUSDE | deep Stamping | BUSDE+Z | |||

| TDC51D+AZ | Cold forming | DC51D+AZ | Q/BQB 425 | Hot dip aluminized zinc plate | |

| TDC52D+AZ | Cold forming | DC52D+AZ | |||

| TS250GD+AZ | Structure | S250GD+AZ | |||

| TS300GD+AZ | Structure | S300GD+AZ | |||

| TS350GD+AZ | Structure | S350GD+AZ | |||

| TS550GD+AZ | Structure | S550GD+AZ | |||

| Available specification range | |||||

| Item | Nominal Size | ||||

| Nominal thickness | 0.22-1.30 | ||||

| Nominal width | 700-1250 | ||||

| nominal length of steel plate | 1000-4000 | ||||

- Q: How are steel coils inspected for dimensional accuracy after processing?

- Steel coils are inspected for dimensional accuracy after processing using various techniques such as laser scanning, ultrasonic testing, and manual measurements. These methods ensure that the coils meet the required specifications and tolerances, guaranteeing their quality and suitability for further use.

- Q: Steel is no doubt a better constructin material but it is only in practice in developed country.i would like that we should high lights the benifits and negatives of steel to make the steel more clear as a construction material.Hope some expert to address this topicMD

- Steel Structure considered as the most efficient and fast in completion of any project, specially the high rise buildings, also the logistics during construction is less complicated than the normal methods, Steel Structure has so many advantages vs the disadvantages, and highly recommended for commercial buildings

- Q: How are steel coils used in the production of furniture?

- Steel coils are commonly used in the production of furniture as they provide strength, durability, and stability. These coils are typically used in the construction of furniture frames, providing a solid foundation for cushions and upholstered components. Additionally, steel coils can be used in the manufacturing of springs, which are essential for providing comfort and support in mattresses, sofas, and other upholstered furniture pieces.

- Q: How are steel coils used in the production of metal panels?

- Steel coils are an essential component in the production of metal panels. These coils, which are typically made from high-quality steel, serve as the raw material for manufacturing various types of metal panels. To begin the production process, the steel coils are first unrolled and flattened using specialized machinery. This allows for a consistent and uniform thickness throughout the sheet. The flattened steel is then cut into the desired length and width, depending on the specific requirements of the metal panel being produced. Once the steel has been cut, it undergoes further processing, such as cleaning and coating. This is done to remove any impurities and protect the steel from corrosion or damage. The coating also enhances the appearance of the metal panel and provides additional durability and longevity. After the cleaning and coating process, the steel sheets are formed into the desired shape using various techniques, such as roll forming or stamping. This allows for the creation of different types of metal panels, including roofing panels, wall panels, and decorative panels, among others. The steel coils used in the production of metal panels are chosen for their strength, durability, and versatility. Steel is known for its excellent structural properties, making it an ideal material for constructing sturdy and long-lasting metal panels. Additionally, steel is highly resistant to environmental factors, such as extreme weather conditions, which further enhances the durability of the metal panels. In conclusion, steel coils play a crucial role in the production of metal panels. They serve as the raw material for manufacturing these panels and undergo various processes to ensure their quality and durability. The use of steel coils allows for the production of a wide range of metal panels that can be used in various industries and applications.

- Q: What is the maximum load capacity for steel coil storage racks?

- The maximum load capacity for steel coil storage racks can vary depending on factors such as the design, dimensions, and construction materials of the rack. It is recommended to refer to the manufacturer's specifications or guidelines for accurate information on the maximum load capacity of a specific steel coil storage rack.

- Q: Can steel coils be used in the production of electrical components?

- Yes, steel coils can be used in the production of electrical components. Steel coils are often used as magnetic cores in transformers and inductors. The magnetic properties of steel make it an ideal material for enhancing the efficiency and performance of electrical components. The coils are wound around the steel core, which helps to concentrate and direct the magnetic field, ensuring smooth and efficient operation. Steel coils are also used in the production of solenoids, motors, generators, and other electrical devices where magnetic fields are crucial for their functionality. Overall, steel coils play a vital role in the production of various electrical components, contributing to their reliable and efficient operation.

- Q: steel can be used to do?

- Stainless steel can be used to (1) industrial use stainless steel (2) building decoration use stainless steel;(3) medical equipment (4) life with stainless steel tableware and the Jawaysteel is a great Chinese company, offer various kinds of stainless steel Maybe you can to their advice

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- Stainless steel is less conductive than copper. However, steel will retain heat longer and thus be distributed more evenly. (hence the thick bottoms, but also for balance). Copper on tea kettles is ideal to bring water up to a boil rapidly but since your not really cooking food, temperature distribution or control doesn't really matter. Now if your cooking sensitive food, then it does matter. For example, the use of a double boiler is preferred for chocolates. Temperature and distribution is critical. As far as relatively inexpensive copper clad pots and pans such as Revereware? Well, I don't see a difference but perhaps they did some testing.

- Q: What are the challenges in welding steel coils?

- In order to guarantee successful and high-quality welds, it is necessary to address various challenges encountered when welding steel coils. One primary challenge involves achieving appropriate joint preparation. Steel coils often exhibit different surface conditions, such as rust, scale, or oil, which must be cleaned or eliminated before welding. This demands extensive cleaning and preparation to establish a clean and reliable welding surface. Another challenge lies in controlling the heat input. Due to the thin nature of steel coils, excessive heat can result in distortion, warping, or even burn-through. Welding operators must exercise careful control over the heat input to prevent such issues and uphold the integrity of the coils. Additionally, the presence of residual stresses poses a significant difficulty. Steel coils typically endure various stresses during the manufacturing, transportation, and handling processes, which can lead to distortion or cracking during welding. To mitigate these stresses and prevent potential defects, sufficient preheating and post-weld heat treatment may be necessary. Ensuring proper weld penetration is also of utmost importance. Steel coils often possess varying thicknesses, making it challenging to achieve consistent and adequate weld penetration throughout the joint. Welding operators must select appropriate welding parameters and techniques to guarantee complete fusion and a robust bond. Lastly, the size and weight of steel coils can create logistical challenges during welding. Specialized equipment and precise positioning are required to handle large and heavy coils, ensuring safe and efficient welding. Additionally, the length of the coils may necessitate multiple passes or continuous welding, demanding skilled operators and meticulous coordination. In conclusion, welding steel coils necessitates careful attention to joint preparation, heat control, stress relief, weld penetration, and logistical considerations. Overcoming these challenges guarantees the production of welded steel coils that are of high quality and durability.

- Q: I have been wanting a new pair of hiking boots, but haven't had the money. I just got a job that requires me to have steel toed boots. The job is only for a few weeks, but I may be required to wear them on other jobs in the future. Regardless of which style I get, I will most likely be buying Red Wing boots. On their website, I see they have steel toed hiking boots. What is the purpose of a steel toed hiking boot? Why would a hiker need to have steel toed boots? Wouldn't that just be more weight? I see that some of their hiking boots have aluminum toes, claiming to be 33% lighter than steel with the same protection. Would these boots be good potential hiking boots as well as suitable for construction or should I just focus on work boots and buy myself some hiking boots at a later date?

- Steel toed boots is a safety factor thing. Wilderness workers ie lumber jacks need safety shoes as well. But for long distance hiking steel toed shoes would be impractical due to the weight and wear and tare on The trails and your body. Get the boots you need for work, get the hiking boots you want after the next paycheck.

Send your message to us

Prepainted Hot Dipped Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords