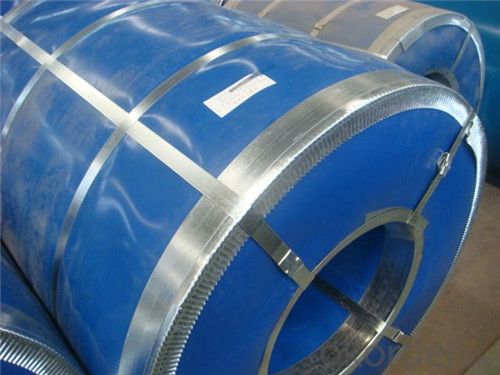

Prepainted Rolled Steel Coil For Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I haven't seen Man of Steel yet, but which one do you think was better? (please no spoilers)

- Well, I haven't seen it Man of Steel but I really see it hard to believe that's better than Superman. To me, Superman with Christopher Reeve is the best movie about Superman ever made. When I first saw it I was amazed. Watching Superman flying for the first time, catching Loise and graving that helicopter before it falls... it was awesome! I loved it! The other movies that followed were bad but this one was amazing. I've seen what other actors have made with the character, but I believe Christopher was the best. He was the perfect man, the perfect gentleman and the best superhero ever. I know that this Superman is for the new generations so it will be more 'real' and more 'suffered' or will have more personal issues dealing with his origins and blah blah blah... and I wish him good luck, but honestly? I stick to the original Superman because whenever I see Christopher Reeve flying around the planet as Superman (hanging from wires-no CGI people!) and I hear that characteristic music I just melt and I'm a child once more. So good luck to the new generation, I really hope they like this new guy and new story, but I'm more than fine with the original version, thank you. Hope it helps! ;)

- Q: What is the role of steel coils in the production of storage shelves?

- Steel coils are used in the production of storage shelves to provide strength and durability. The coils are processed and shaped into various components of the shelf, such as the frame, shelves, and brackets. This ensures that the shelves are able to withstand heavy loads and maintain their structural integrity over time. Steel coils also offer corrosion resistance, making them suitable for use in storage environments.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are highly regarded for their exceptional strength and durability, making them superior to other types of metal coils. Steel is known for its high tensile strength, allowing it to withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require a high level of structural integrity, such as in the construction and automotive industries. In addition to their strength, steel coils also offer excellent corrosion resistance. Various protective layers, such as zinc or paint, can be applied to steel to prevent rusting and ensure longevity. This makes steel coils suitable for outdoor and marine environments where exposure to moisture and harsh weather conditions is common. Furthermore, steel coils have a diverse range of mechanical properties that can be customized through different manufacturing processes. This allows for the production of steel coils with specific characteristics, including high ductility, heat resistance, or electrical conductivity, to meet the requirements of various industries. When compared to other metal coils, such as aluminum or copper, steel coils often have a lower cost. Steel is one of the most economical metals available, and its abundance in nature contributes to its affordability. This makes steel coils a cost-effective choice for many applications, especially when large quantities are required. Overall, steel coils are distinguished by their exceptional strength, durability, corrosion resistance, versatility, and affordability. These qualities make steel coils the preferred choice for a wide range of industries, including construction, manufacturing, transportation, and energy.

- Q: When i was 15 i got caught steeling at Super A yes i know i cant believe it. They didnt call the cops or anything they released me to my aunt they took my name and adress and everythimg they said it wouldnt be on my record. But I'm not so sure. Will it be on my record if they didn't call the cops?i live in california. Is there any way i can check my record?

- Steeling? What's that? Did you take a piece of steel and weld it? I am confused?

- Q: Please give me the name of the steel, and the percentage of materials from what It consists, if you can give me five types of steel it will be better so I can decide. Thanks.

- Without okorder .. Plus few other useful resources. In the end, there's no one best steel, not even 5. It all depends on the knife design, use, edge thickness, what you cut, etc...

- Q: How do steel coils contribute to strength and stability in structures?

- Steel coils are essential components in many structures due to their significant contribution to strength and stability. The inherent properties of steel, combined with the unique design of coils, make them an ideal choice for enhancing the structural integrity of various applications. Firstly, steel itself is renowned for its exceptional strength. It has a high tensile strength, which means it can resist large amounts of tension without breaking or deforming. When steel is formed into coils, it further enhances its strength by distributing the load evenly across the entire structure. This uniform distribution of force helps prevent localized stress concentrations, ensuring that the structure can withstand heavy loads and external pressures more effectively. Additionally, steel coils provide stability to structures by offering rigidity and resistance against deformation. Steel is known for its stiffness, which prevents excessive flexing or bending under loads. The tightly wound coils create a robust and compact structure that can efficiently resist dynamic forces, such as wind, earthquakes, or vibrations. This high resistance to deformation minimizes any potential damage to the structure, thereby maintaining its stability and integrity. Moreover, steel coils also contribute to the longevity and durability of structures. Steel possesses remarkable durability, as it is highly resistant to corrosion, rust, and deterioration over time. This longevity ensures that structures built with steel coils can remain strong and stable for extended periods, requiring minimal maintenance or repairs. Furthermore, steel coils offer versatility in design and construction. The ability to shape steel into various coil sizes and configurations allows for customization based on specific structural requirements. Architects and engineers can utilize steel coils to create complex structures while maintaining their strength and stability. This versatility allows for innovative and efficient design solutions, making steel coils a preferred choice in many construction projects. In conclusion, steel coils play a crucial role in enhancing the strength and stability of structures. The inherent strength of steel, combined with the unique design of coils, provides structures with the necessary rigidity, resistance to deformation, and durability. Additionally, the versatility of steel coils allows for customization and innovative design solutions. Overall, steel coils significantly contribute to the overall integrity and longevity of structures, making them an essential component in the construction industry.

- Q: How do steel coils compare to aluminum coils?

- Steel coils are generally stronger and more durable than aluminum coils. They have a higher tensile strength and better resistance to impact and abrasion. However, aluminum coils are lighter, more corrosion-resistant, and have better thermal conductivity. The choice between steel and aluminum coils depends on the specific application and the desired characteristics such as strength, weight, and corrosion resistance.

- Q: What are the different methods of edge camber correction for steel coils?

- There are several methods used for edge camber correction in steel coils, depending on the specific requirements and equipment available. Some of the common methods include: 1. Mechanical Edge Trimming: This method involves trimming the edges of the coil using mechanical tools such as shears or slitters. It helps to remove excess material and correct the camber. This method is often used for smaller coils or when the camber is minimal. 2. Tension Leveling: Tension leveling is a process where the coil is passed through a series of adjustable rollers under tension. The tension helps to elongate the steel and reduce the camber. This method is effective for correcting moderate camber and is commonly used for larger coils. 3. Roller Leveling: Roller leveling is similar to tension leveling, but instead of adjustable rollers, the coil is passed through a series of fixed rollers. These rollers exert pressure on the steel to flatten it and correct the edge camber. This method is often used for thicker and heavier coils. 4. Heat Straightening: Heat straightening involves applying controlled heat to the edges of the coil to soften the steel. Once the steel becomes malleable, external force is applied to straighten the edges. This method is suitable for correcting severe edge camber but requires specialized equipment and expertise. 5. Combination Methods: In some cases, a combination of different methods may be used to achieve the desired edge camber correction. For example, mechanical edge trimming may be followed by tension leveling or roller leveling to further straighten the edges. It is worth mentioning that the choice of method depends on various factors such as the severity of camber, coil dimensions, material properties, and available equipment. It is essential to evaluate these factors and consult with experts to determine the most suitable method for edge camber correction in steel coils.

- Q: How are steel coils cleaned before use?

- Steel coils are cleaned before use through a process known as pickling. Pickling is a chemical treatment that helps remove any impurities, scale, rust, and other contaminants from the surface of the steel coils. The initial step involves the steel coils being immersed in an acid bath, typically a mixture of hydrochloric acid and sulfuric acid. This acid solution helps dissolve any rust, scale, and other surface impurities. The duration of the immersion depends on the extent of contamination and the desired cleanliness level. After the pickling process, the coils are thoroughly rinsed with water to remove the acid solution and any remaining residue. This step is crucial to prevent further corrosion or chemical reactions. Once the rinsing is complete, the coils are often subjected to a drying process to remove any remaining moisture. This can be done through air drying, using high-pressure air blowers, or by passing the coils through heated chambers. After the cleaning process, the steel coils are now ready for use in various applications such as manufacturing, construction, or any other industry that requires high-quality steel products. The pickling process ensures that the coils have a clean, smooth, and corrosion-resistant surface, allowing them to perform effectively and meet the desired specifications.

- Q: What are the common coil processing equipment used in the industry?

- Some common coil processing equipment used in the industry include coil slitting machines, coil leveling machines, coil cutting machines, coil recoiling machines, and coil feeding systems. These machines are used to process coils of various materials, such as steel, aluminum, and copper, into desired sizes and shapes for further manufacturing processes.

Send your message to us

Prepainted Rolled Steel Coil For Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords