All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

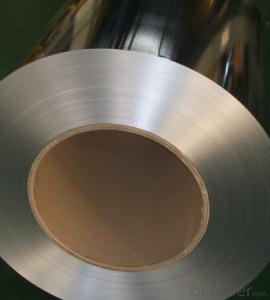

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How can surface defects in stainless steel coils be avoided during manufacturing?

Surface defects in stainless steel coils can be avoided during manufacturing by implementing proper cleaning and inspection processes, using high-quality materials, maintaining precise control over temperature and pressure during production, minimizing handling and transportation damage, and ensuring regular maintenance of manufacturing equipment.

What are the maximum and minimum coil thickness tolerances?

The maximum and minimum coil thickness tolerances refer to the acceptable deviation in thickness measurements for a coil. These tolerances vary depending on the specific industry and application. Generally, the maximum coil thickness tolerance defines the upper limit or the maximum amount by which the actual thickness can exceed the specified thickness. Conversely, the minimum coil thickness tolerance denotes the lower limit or the minimum amount by which the actual thickness can be below the specified thickness. The specific values for these tolerances are determined by the manufacturer or industry standards to ensure quality control and meet the desired specifications.

How is stainless steel coil used in the oil and gas fabrication industry?

Stainless steel coil is commonly used in the oil and gas fabrication industry for various applications. It is often utilized for manufacturing pipes, tubing, and fittings due to its corrosion-resistant properties and excellent mechanical strength. Stainless steel coils are also used for fabricating pressure vessels, heat exchangers, and storage tanks, as they can withstand high temperatures and harsh operating conditions. Additionally, stainless steel coil is employed in the fabrication of offshore platforms and subsea equipment, where its durability and resistance to corrosion are crucial for ensuring long-term reliability and safety in the oil and gas industry.

What is the fatigue strength of stainless steel coils?

The fatigue strength of stainless steel coils can vary depending on various factors such as the specific grade of stainless steel, the manufacturing process, the coil's dimensions, and the applied load conditions. It is generally higher than that of other materials due to stainless steel's excellent resistance to corrosion and its inherent strength properties. However, to determine the exact fatigue strength of stainless steel coils, it is essential to conduct specific fatigue tests and analysis on the specific coil in question.

How does punching affect the surface of a stainless steel coil?

Punching stainless steel coil can alter its surface by creating indentations or holes depending on the force and size of the punch. The impact can also cause slight deformation or distortion in the material.

Wholesale Stainless Steel Coil from supplier in Argentina

Whether you are in the construction, manufacturing, or any other industry requiring stainless steel coil products, we can cater to your specific needs. Our team of experienced professionals is dedicated to delivering exceptional customer service and ensuring that you receive the highest quality products.

We understand the importance of timely delivery and competitive pricing, and we strive to exceed your expectations in these areas. Our close relationships with reputable manufacturers and suppliers allow us to offer competitive prices without compromising on quality.

In addition to sales and quotes, we also provide technical support services. Our knowledgeable team can assist you with any inquiries or concerns you may have regarding the selection, installation, or maintenance of stainless steel coils. We are committed to helping you find the most suitable solution for your project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the advantage of extensive resources and a strong global network. This enables us to provide comprehensive procurement services, ensuring a smooth and efficient supply chain for your stainless steel coil needs.

Our years of market development in Argentina have given us valuable insights into the local industry trends and requirements. We are well-positioned to understand and address the unique challenges you may face, ensuring that our products and services meet your specific needs.

Whether you require standard stainless steel coils or customized solutions, we are here to assist you every step of the way. Contact us today to discuss your stainless steel coil requirements and experience the exceptional service and quality products we offer.

We understand the importance of timely delivery and competitive pricing, and we strive to exceed your expectations in these areas. Our close relationships with reputable manufacturers and suppliers allow us to offer competitive prices without compromising on quality.

In addition to sales and quotes, we also provide technical support services. Our knowledgeable team can assist you with any inquiries or concerns you may have regarding the selection, installation, or maintenance of stainless steel coils. We are committed to helping you find the most suitable solution for your project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the advantage of extensive resources and a strong global network. This enables us to provide comprehensive procurement services, ensuring a smooth and efficient supply chain for your stainless steel coil needs.

Our years of market development in Argentina have given us valuable insights into the local industry trends and requirements. We are well-positioned to understand and address the unique challenges you may face, ensuring that our products and services meet your specific needs.

Whether you require standard stainless steel coils or customized solutions, we are here to assist you every step of the way. Contact us today to discuss your stainless steel coil requirements and experience the exceptional service and quality products we offer.