Prepainted Hot Dipped Galvalume Steel Sheet In Coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted Hot Dipped Galvalume Steel Sheet in Coils

1.Structure of Prepainted Hot Dipped Galvalume Steel Sheet in Coils

Prepainted Hot Dipped Galvalume Steel Sheet in Coils is one kinds of building material on construction.Steel sheet in melting zinc trough, the sticking of a layer of zinc sheet. At present mainly adopts continuous galvanizing process, namely the continuous roll of steel plate in the melt zinc plating tank made of galvanized steel sheet; Alloying of galvanized steel. This kind of steel plate is made by hot dip method, but after the slot, immediately heated to a temperature of about 500 ℃, it make the generation of zinc and iron alloy membrane. This kind of galvanized volumes with good coating of the sex and weldability.

Color coated steel coil(ppgi) is made by the processes of chemical preconditioning, first coating, precision coating and so on through a continuous rapid unit internationally in recent three decades. Its quality is more uniform and stable than the one whose surface of the formed metal is coated single or brushed one.

2.Main Features of Prepainted Hot Dipped Galvalume Steel Sheet in Coils.

1) Rust-proof

2) Water-proof

3)Durable using

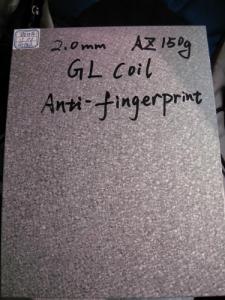

3. Prepainted Hot Dipped Galvalume Steel Sheet in Coils Images

4. Prepainted Hot Dipped Galvalume Steel Sheet in Coils Specification

1)Based raw material: Hot rolled steel coils or Cold rolled steel coils

2) Thickness

3) Width

4)Coating mass

5) Spangle

6)Surface treatment

7)Coil inner diameter

8)Painting kind

9)Painting color

10)Painting thickness

5.FAQ of Prepainted Hot Dipped Galvalume Steel Sheet in Coils

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How to contact with you?

You can go to our website to find what you need and send the inquiry on line, or you can contact with the manager you know in our company dirrectly.

- Q: I bought a steel pendant on eBay, but it turned out to be too shiny.I've read on a couple forums that if I leave it soaked in urine for 2 days, it will get duller.Now, if it really does get duller, will the pendant get rusty afterwards?So is the shiny surface the only thing that prevents it from rusting?Any simple, non-urine ideas on how to make it duller are welcome too.Thanks!

- Stainless steel will rust under proper conditions. I live on a boat on salt water, trust me. If the urine works it won't be prone to rusting any more than before. It's not the shine that inhibits rusting with stainless steel, it the % of carbon in the steel, compared to regular steel. IF the urine works it's because it is acidic (a mild acid). Wash it with a small brush and some baking soda to neutralize the acid when your done. A much stronger acid would be swimming pool acid. (Muriatic acid) but be careful you might test a spot with a Q tip on the back. If you try Muriatic acid it would take seconds.Then wash in baking soda water to remove all acid.. SS

- Q: What is the shelf life of a steel coil?

- The duration for which a steel coil remains usable depends on several factors, including the type of steel, storage conditions, and protective measures implemented. Steel coils can generally be stored for a few months to several years. If a steel coil is stored appropriately in a controlled environment with suitable temperature, humidity, and ventilation, its lifespan can be extended. Moreover, if the coil is coated with protective substances like oil or anti-corrosion coatings, its shelf life can be further prolonged. However, if a steel coil is exposed to unfavorable storage conditions such as high humidity, extreme temperatures, or corrosive substances, its shelf life can significantly decrease. Rust and corrosion can occur due to exposure to moisture and oxygen, leading to a decline in quality and structural integrity. To maximize the shelf life of a steel coil, it is crucial to store it in a well-ventilated, dry area, away from direct sunlight and corrosive substances. Regular inspections and maintenance, including cleaning and reapplication of protective coatings, can also help preserve the coil's quality. Ultimately, it is essential to consult the manufacturer or supplier of the steel coil for specific recommendations regarding shelf life, as different types of steel may have varying levels of durability and specific storage requirements.

- Q: What are the different surface finishes for steel coils?

- There are several different surface finishes for steel coils, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q: How are steel coils inspected for bendability?

- Steel coils are inspected for bendability using a variety of methods to ensure their suitability for various applications. One common inspection method is the 3-point bend test, where the coil is subjected to a bending force at three specific points along its length. This test helps determine the coil's resistance to bending without fracturing or breaking. During the 3-point bend test, the coil is placed on a support system with two fixed points and one movable point. A force is then applied to the movable point, causing the coil to bend. The amount of force required to achieve a specific level of bending is measured and compared against acceptable standards. Another method used for inspecting steel coils is the mandrel bend test. In this test, a mandrel of a specific diameter is inserted into the coil and bent to a specified angle. The coil is then examined for any signs of cracking or deformation. This test helps determine the coil's flexibility and ability to withstand bending without damage. Visual inspection is also an important part of the inspection process. Trained inspectors visually examine the coil for any visible defects such as cracks, deformations, or irregularities. They also check for proper coil dimensions and uniformity throughout. In addition to these methods, non-destructive testing techniques like ultrasonic testing or magnetic particle inspection may be used to detect any internal defects or flaws that may affect the bendability of the coil. Overall, a combination of mechanical testing, visual inspection, and non-destructive testing methods are employed to ensure that steel coils meet the required bendability standards. These inspections help ensure the quality and reliability of the steel coils for various industries where bendability is a critical factor.

- Q: Can steel coils be returned if they are damaged?

- Yes, steel coils can typically be returned if they are damaged. However, the return policy may vary depending on the supplier or manufacturer. It is advisable to contact the seller or review the terms and conditions of the purchase to determine the specific return policy for damaged steel coils.

- Q: How are steel coils inspected for paint adhesion?

- Steel coils are inspected for paint adhesion through various methods such as visual examination, tape test, and cross-cut adhesion test. These tests involve visually inspecting the surface for any paint defects, applying adhesive tape to check if the paint adheres properly, and making cross-cuts to assess the adhesion strength.

- Q: How are steel coils used in the manufacturing of power transmission towers?

- Steel coils are used in the manufacturing of power transmission towers as they are shaped and formed into the required structural components, such as beams and brackets. These coils are processed through rolling mills to obtain the desired thickness and shape, ensuring the strength and durability of the towers. The steel coils provide the necessary strength and structural integrity to support the weight of the transmission lines, withstand environmental conditions, and ensure reliable power transmission.

- Q: my homework is a breif description on steel pipe. for plumbing/gas.please help me i dont have a clue where to start, something about the thread and where its used.Thanks,

- sophisticated thing. browse in google. this can help!

- Q: what is the history of steel and how did they start making it, i need a link or an answer that is five paragraphs long. plus i need examples of subtitles about the history of steel. i am doing this for a science project and hope that someone can help me out.thanks

- There's wide history of steel, you can read different tutorials online to know more about it. Check wiki for detailed information.

- Q: I have a tiara and it oxidized and I'm not sure what material it is. I know it it isn't metal so i was wondering if is steel? Also if it's steel, can I do something to clean it?

- Yes - Steel can oxidize, its most commonly called rust Steel is a metal. Depending on the level of oxidation, you might be able to polish it with very fine steel wool. If is is really bad, then you might need a chemical cleaner such as Naval Jelly, which can be found at the hardware store. But the Naval Jelly might discolor the metal, so then you might need to polish it afterward to return its finish.

Send your message to us

Prepainted Hot Dipped Galvalume Steel Sheet In Coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords