High Coating Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

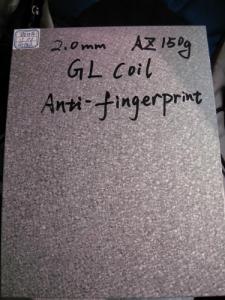

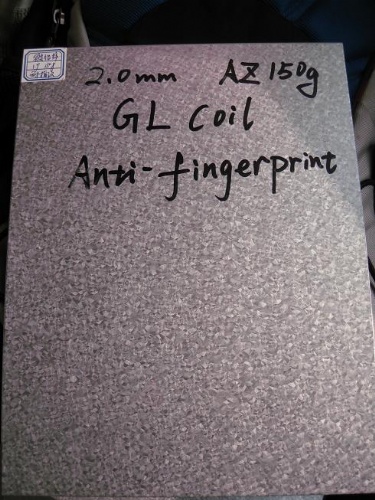

Hot Dipped Galvalume Sheet as per ASTM A 792 CS (Type A), AZ 150, Anti Fingerprint,

~ Regular Spangle, with side one PVC Film

~ AL 55%, ZN 42%, Si > 1.5%

SIZE (MM) (TCT) MOQ (MTS)

1.0 x 1250 x C 100

1.5 x 1250 x C 100

2.0 x 1250 x C 100

COIL ID: 508MM

COIL WEIGHT: 4-6MTS

VALIDITY: 3 WORKING DAYS

PAYMENT: T/T WITH 20% DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LIST

SHIPMENT: 75 DAYS AFTER T/T 20% DOWNPAYMENT

- Q: How are steel coils used in the manufacturing of agricultural equipment?

- Steel coils are used in the manufacturing of agricultural equipment as they serve as a raw material for various components such as frames, chassis, and structural supports. These coils are shaped, cut, and welded to form the necessary parts, providing strength, durability, and stability to the equipment.

- Q: For the purpose of blade crafting. I need to heat treat this low quality steel i got.It's ASTM A36Is heat treatable and temperable?

- A36 is plain carbon structural steel. A36 could almost be considered junk steel. It is not suitable for cutting tools in any respect, as it is far to soft to hold an edge. A36 generally cannot be heat-treated, A36 can only be strengthened by cold-working, and even then, only up to about 60,000 psi. Heating the steel will only make it softer. The only real virtue of A36 is that it's easy to work with, it's easily cut and machined and it is very easy to weld. This is good for making steel structure, but not for knives. Probably the most popular material for knife blades is type 440C stainless. 440C is easy to work with in the un-treated state, and the heat treatment procedure is relatively simple.

- Q: How do steel coils contribute to the agricultural sector?

- Steel coils contribute to the agricultural sector by being used in the manufacturing of agricultural machinery and equipment. These coils are used to create components such as plows, harrows, tillers, and seeders, which are essential for cultivating, planting, and harvesting crops. The durability and strength of steel coils make these agricultural machinery and equipment more robust, reliable, and efficient, thereby improving productivity and ensuring higher crop yields.

- Q: What is the average amount carbon emissions of steel per pound produced?

- Carbon okorder /... - Similar pages - Life-cycle energy and emissions of marine energy devices | Carbon ...Carbon dioxide emissions per unit mass of steel: 1.75 tCO2/tonne steel ; Total mass of steel in device: 665 tonnes ; Carbon dioxide emissions due to .

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. This coating process involves applying a thin layer of holographic material onto the surface of the steel coils, creating a visually striking and distinctive holographic pattern.

- Q: Can steel coils be customized?

- Yes, steel coils can be customized according to specific requirements such as size, thickness, width, and even surface finish. Customization allows manufacturers to meet the unique needs of various industries and applications.

- Q: I have two guitars, a nylon stringed classical, and a steel stringed acoustic, I find the nylon strings easier to play, but doesn't have as good of sound as the steel stringed, and when I play with the steel strings, it really hurts my fingers, and if I play just a little bit, it feels like the high e string is going to cut my finger. Are the strings too high? What can I do to make the steel strings easier to play?

- find an online tuner and tune the strings to the tuning you want. trust me, guitar hurts your fingers after a while. but your skin gets used to it's, it's what ever.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into rails. These coils are transformed into long, straight sections of steel that form the main structure of the track. This process involves cutting, bending, and welding the coils to create the desired rail shape and dimensions. The resulting rails are then installed on rail beds to provide a durable and reliable foundation for trains to run on.

- Q: Okay basically bought my girlfriend Tiffany sterling silver necklace for her birthday and now christmas is coming up i want to buy her this DG Necklace. BUT i have discovered its steel. And its ?110. I am not a rich man i am infact quite young and we have been together for an incredibly long time! I wanted to know is Steel seen as a cheap necklace, whats your say? Don't give me all this bull about her being grateful as she does not expect this. BUT I WANT IT TO BE NICE. Whats your say? Is Steel good? Does it get dirty? Does it shine? Is it worth it? Thanks x

- STAINLESS steel is fine. It is the modern alternative. Whether it is seen as a `cheap` necklace depends on the quality of the necklace itself in this case, not what it is made of. At ?110 it should be a well-made and a quite original piece. You should have put a link showing it . Stainless steel will not rust, it`s washable, and will keep it shine forever. My own guess (based on the limited info you have supplied) is that it sounds like a very acceptable gift.

- Q: What is the process of recoiling steel coils?

- The process of recoiling steel coils involves rewinding or unrolling large steel coils to create smaller, more manageable coils. This process is typically carried out in steel processing plants or coil service centers. The first step in the recoiling process is to identify the appropriate coil to be recoiled. This selection is based on factors such as coil size, weight, and quality. Once the coil is chosen, it is placed onto a recoiling machine, which is equipped with various mechanisms to facilitate the recoiling process. The recoiling machine consists of a mandrel or drum, around which the coil is wound or unwound. The coil is secured onto the mandrel, either by mechanical clamps or hydraulic pressure, to ensure it remains stable during the recoiling process. In the case of rewinding or recoiling a large coil into smaller coils, the machine starts by unwinding the original coil. This is done by rotating the mandrel in the opposite direction, causing the coil to gradually unroll. As the coil unwinds, it passes through various straightening and flattening mechanisms, which help to ensure the coils are produced with consistent dimensions and quality. Once the original coil is completely unwound, the machine starts the rewinding process. The smaller coils are created by winding the steel strip onto the mandrel in a controlled manner. The speed and tension of the rewinding process are carefully regulated to prevent any damage to the steel strip. During the recoiling process, various quality control measures are implemented to ensure the produced coils meet the desired specifications. These may include monitoring the thickness, width, and surface quality of the steel strip, as well as conducting periodic inspections to detect any defects or irregularities. Once the rewinding process is completed, the smaller coils are typically removed from the mandrel and prepared for further processing or shipment. This may involve applying protective coatings, labeling, or packaging the coils, depending on their intended use. In summary, the process of recoiling steel coils involves unwinding large coils, straightening and flattening the steel strip, and rewinding it onto a mandrel to create smaller, more manageable coils. This process requires specialized machinery and careful control to ensure the quality and consistency of the recoiled coils.

Send your message to us

High Coating Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords