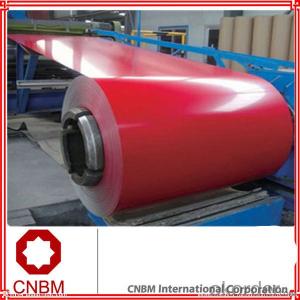

Prepainted Galvanized Steel Sheet In Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted Galvanized Steel Sheet In Coils

SPECIFICATION:

Product name | Prepainted Galvanized Steel Sheet In Coils |

thickness | 0.2mm—1.0mm |

width | 600mm—1500mm |

zinc coating | 30g-180g |

Paint Thickness | Top:15-28um, back:5-10um |

standard | ASTM A792, JIS G3321, JIS G3317, GB |

material | SGCC/SGCH |

Base Plate | Hot dipped Galvanized steel sheet,hot dipped aluzinc steel sheet |

Surface Paint | PE,PP |

Color Series | RAL color number series |

Equipment | Double coating one baking |

packing | 1. standard seaworthy package : waterproof paper/iron sheet/steel strip/steel pallet 2. According to customers' requirements |

Coil Wgt. | 3Mt - 8Mt |

Coil ID | φ508mm,φ610mm |

payment | T/T or L/C |

min order | 25 tons |

Capacity | 4000Mt/week |

delivery time | within 40 days upon receipt original L/C or advance payment |

APPLICATION:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers,

video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, etc.

- Q: What are the different types of steel coil coatings for corrosion resistance?

- There are several different types of steel coil coatings that are specifically designed to provide corrosion resistance. These coatings can be categorized into two main types: organic coatings and metallic coatings. 1. Organic Coatings: - Polyester: Polyester coatings are commonly used for steel coil applications due to their excellent corrosion resistance and durability. They offer good weatherability and resistance to chemicals, making them suitable for outdoor applications. - Polyvinylidene Fluoride (PVDF): PVDF coatings are highly resistant to UV radiation, weathering, and chemicals. They provide exceptional durability and are often used in demanding environments such as coastal areas or industrial settings. - Polyurethane: Polyurethane coatings offer excellent abrasion resistance and provide a high level of corrosion protection. They are commonly used in applications where there is a higher risk of mechanical damage or exposure to harsh conditions. - Epoxy: Epoxy coatings provide excellent adhesion and chemical resistance. They are often used in industrial applications where resistance to chemicals, solvents, and oils is required. 2. Metallic Coatings: - Galvanized Coatings: Galvanized coatings involve applying a layer of zinc to the steel surface through a hot-dip or electroplating process. This creates a barrier between the steel and the surrounding environment, providing effective corrosion protection. Galvanized coatings are widely used in various industries due to their cost-effectiveness and good durability. - Galvannealed Coatings: Galvannealed coatings are similar to galvanized coatings but undergo an additional heat treatment process. This results in a coating with increased hardness and improved paint adhesion, making it suitable for applications that require additional surface protection or paintability. It is important to consider the specific requirements of the application and the level of corrosion resistance needed when selecting the appropriate steel coil coating. Consulting with coating manufacturers or industry experts can help determine the most suitable coating for a particular application.

- Q: I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Sounds like the abrasive surface got blinded, coated with something that prevented the abrasive particles from touching the steel. It is possible to have vastly different hardnesses in a single piece of steel. Case hardening, carburizing, induction hardening, heat affected zone from welding, differences in work hardening, and presence of inclusions are some of the things that can create hardness variation within a single piece. But... sounds like you are working with a sheet which is unlikely to have any of these conditions. So... it was probably the grinding disk

- Q: What are the dimensions of steel coils used in the storage tank industry?

- The dimensions of steel coils used in the storage tank industry can vary depending on the specific requirements of the tank being manufactured. However, in general, steel coils used for storage tanks are typically available in various sizes and thicknesses. The width of steel coils can range from around 600 millimeters to 2,400 millimeters, while the length can vary from several meters to tens of meters. The thickness of the coils can also vary, typically ranging from 1.5 millimeters to 10 millimeters or more. These dimensions are determined by factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank. The specific dimensions for a given storage tank project would be determined by the tank manufacturer or designer, in accordance with industry standards and specific project specifications.

- Q: Can steel coils be painted?

- Yes, steel coils can be painted. Painting steel coils not only enhances their aesthetic appearance but also provides a protective coating against corrosion and other environmental factors. The coils are typically pre-treated and primed before the application of paint to ensure proper adhesion and durability.

- Q: What is the difference between carbon steel and spring steel?? And which is the better one to make swords with??

- Neuropathy Solution can help people of neuropathy to eliminate all the outward indications of this problem including : tingling, prickling feeling , numbness of the area round the affected nerves, quick problems , sharp as well as using feeling in the nerves. Dr. Randall Labrum, the author of this unique guide feels that you will eliminate most of the outward indications of neuropathy and eliminate that dangerous illness permanently.

- Q: I bought a stainless steel water bottle today. I really like it, but there is no drinking spout, it just has a lid that screws on and off, and an open hole to fill it and drink out of. Is this normal for these bottles? Or do they usually come with a spout to drink from? I don't want to look like an idiot at the gym drinking from this cool bottle with no spout if there's supposed to be one! haha.

- That's normal. I'm sure there are caps that you can get that have a built in spout though.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems as they are shaped and formed into various components such as pipes, tubes, and fittings. These coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the irrigation system.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q: Are Steel buildings Fire Resistant, just want to know as I am going to owe it . Suggestions required…………..

- Steel okorder

Send your message to us

Prepainted Galvanized Steel Sheet In Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords