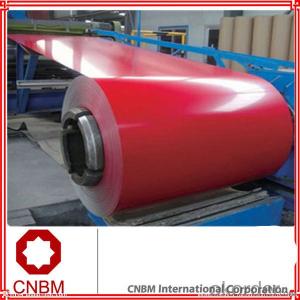

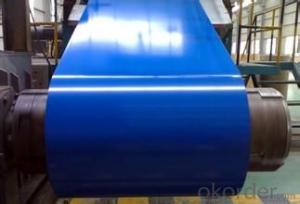

High Quality of Prepainted Galvanized Steel Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

- Q: Can steel sheets be used for roofing?

- Yes, steel sheets can be used for roofing. Steel is a durable and strong material that offers excellent protection against weather elements and is often used as a roofing material in residential and commercial buildings.

- Q: Are steel sheets affected by UV radiation?

- Yes, steel sheets can be affected by UV radiation. Over time, prolonged exposure to UV radiation can cause steel sheets to undergo a process called photo-oxidation, leading to degradation, discoloration, and potential loss of strength. To protect steel sheets from UV damage, they are often coated with specialized finishes or paints that contain UV stabilizers or inhibitors.

- Q: What is the difference between plain carbon steel sheet and stainless steel sheet?

- Plain carbon steel sheet and stainless steel sheet are both types of steel sheets, but they have several distinct differences. The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made up of iron and carbon, with small amounts of other elements such as manganese and silicon. It is known for its strength and durability, making it suitable for a wide range of applications. However, plain carbon steel is prone to rust and corrosion when exposed to moisture or certain chemicals. On the other hand, stainless steel sheet is made up of iron, carbon, and a minimum of 10.5% chromium. This addition of chromium forms a protective layer on the surface of the steel, known as a passive film, which prevents corrosion and rusting. Stainless steel is highly resistant to stains, heat, and corrosion, making it ideal for applications where hygiene and durability are crucial, such as in the food and medical industries. Another significant difference between the two types of steel sheets is their appearance. Plain carbon steel sheet has a dull grey finish, while stainless steel sheet has a shiny, reflective surface. This aesthetic difference is often a consideration in industries where the visual appeal of the material is important, such as architectural or interior design applications. Furthermore, stainless steel sheet has a higher price point compared to plain carbon steel sheet. This is due to the additional alloying elements, such as chromium and nickel, which are added to enhance its corrosion resistance and other properties. The higher cost of stainless steel is often justified by its superior performance and longevity in corrosive environments. In summary, the key differences between plain carbon steel sheet and stainless steel sheet are their composition, properties, appearance, and price. Plain carbon steel is strong but prone to rust, while stainless steel is corrosion-resistant and has a shiny finish. The choice between the two depends on the specific requirements of the application, including the need for corrosion resistance, aesthetics, and budget.

- Q: How is the weight of the steel plate calculated?

- Steel plate is made of molten steel, cooled and compressed into flat steel.The steel plate is flat, rectangular, and can be rolled directly or cut from a wide strip of steel.

- Q: What are the different methods of surface texturing for steel sheets?

- There are several methods of surface texturing for steel sheets, including mechanical methods such as embossing, engraving, and milling, as well as chemical methods like acid etching and electrochemical etching. Other techniques include laser texturing, shot blasting, and coating applications like powder coating or painting. Each method offers unique advantages and can be chosen based on the desired texture, functionality, and aesthetic requirements of the steel sheets.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets can vary depending on the specific grade and thickness of the steel being used. However, as a general range, the average yield strength of steel sheets typically falls between 250 and 600 megapascals (MPa). It is important to note that different steel grades, such as mild steel, high-strength low-alloy (HSLA) steel, or stainless steel, will have different average yield strengths. Additionally, the thickness of the steel sheet can also impact its yield strength, with thinner sheets generally having higher yield strengths. Therefore, it is crucial to consult the specifications and standards provided by the manufacturer or industry guidelines to determine the specific average yield strength for a particular steel sheet.

- Q: What are the standard sizes of steel sheets?

- The standard sizes of steel sheets vary, but some common dimensions include 4x8 feet, 4x10 feet, and 5x10 feet.

- Q: Can steel sheets be used in the electronics industry?

- Yes, steel sheets can be used in the electronics industry. While electronic devices are typically made with materials such as plastic and aluminum, steel sheets can still play a role in the manufacturing process. Steel sheets are commonly used to create structural components, enclosures, brackets, and other parts in electronic devices. They provide strength, durability, and protection for delicate electronic components. Steel sheets are also used for shielding purposes to prevent electromagnetic interference (EMI) in electronic equipment. Overall, steel sheets have several applications in the electronics industry, making them a viable material choice for certain components and enclosures.

- Q: Can steel sheets be used for solar panel frames?

- Yes, steel sheets can be used for solar panel frames. Steel is a commonly used material for solar panel frames due to its strength, durability, and cost-effectiveness. It provides adequate support and stability to hold solar panels securely in place, making it a suitable choice for constructing solar panel frames.

- Q: Are steel sheets suitable for HVAC equipment?

- Yes, steel sheets are suitable for HVAC equipment. Steel is a durable and strong material that can withstand high temperatures, resist corrosion, and provide structural support. It is commonly used in the construction of HVAC systems, such as ductwork, air handlers, and exhaust systems, due to its excellent mechanical properties and ability to meet the demands of the HVAC industry.

Send your message to us

High Quality of Prepainted Galvanized Steel Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords