Best Prepainted Galvanized steel Coil in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 32423 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized steel Coil :

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

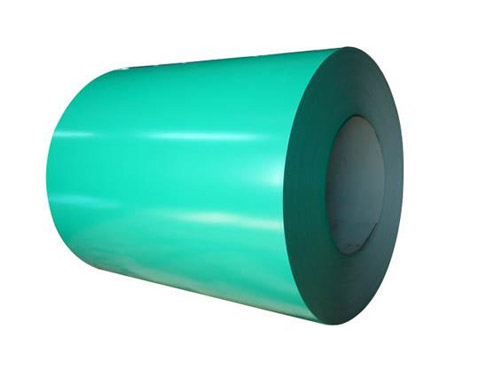

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: How do steel coils contribute to the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery as they provide the necessary strength and durability required for heavy-duty equipment. These coils are often used to fabricate components such as frames, chassis, and structural supports, ensuring stability and reliability of the machinery. Additionally, steel coils can be easily shaped and welded, allowing for customization and versatility in design, ultimately contributing to the overall efficiency and functionality of agricultural machinery.

- Q: What are the challenges in coil slitting for narrow strip widths?

- The challenges in coil slitting for narrow strip widths include maintaining consistent tension throughout the process, minimizing edge burrs and camber, preventing material damage or deformation, and ensuring accurate width measurements and tolerances. Additionally, handling and feeding thin strips can be more difficult, as they are more prone to wrinkling, telescoping, or jamming during the slitting operation. Overall, achieving precision and high-quality results in coil slitting for narrow strip widths requires advanced equipment, expertise, and careful attention to detail.

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils can vary depending on the specific application and industry. However, they are typically available in widths ranging from 0.5 inches to 72 inches and thicknesses ranging from 0.005 inches to 0.5 inches. The length of steel coils can vary as well, but they are commonly found in lengths of 100 feet to 1000 feet.

- Q: What are the different types of steel coil slitting lines?

- There are several different types of steel coil slitting lines that are used in the metal processing industry. These lines are designed to cut large coils of steel into narrower strips, which can then be used for various applications. 1. Loop Slitting Lines: Loop slitting lines are the most common type of slitting line used in the industry. They consist of a decoiler, which holds the coil, a slitter head that cuts the coil into strips, and a recoiler, which winds the strips back into smaller coils. Loop slitting lines are versatile and can handle a wide range of coil widths and thicknesses. 2. Scrap Chopper Slitting Lines: Scrap chopper slitting lines are similar to loop slitting lines but include a scrap chopper unit. This unit cuts any excess material from the edges of the coil before it is slit into strips. This helps to improve the efficiency of the slitting process and reduces waste. 3. Double Loop Slitting Lines: Double loop slitting lines are used for high-speed slitting of thin-gauge coils. They feature two looping pits, which allow for continuous operation. While one coil is being processed, the other is being prepared for slitting, ensuring minimal downtime. 4. Turret Head Slitting Lines: Turret head slitting lines are designed for high-volume production and can process multiple coils simultaneously. They feature a turret head with multiple slitter knives, which can be quickly rotated to switch between different coil widths. This allows for faster and more efficient production. 5. Rotary Shear Slitting Lines: Rotary shear slitting lines are used for thicker and harder materials. They use a rotary shear instead of a slitter head to cut the coil into strips. The rotary shear offers better cutting performance and can handle higher tensile strength materials. 6. Combination Slitting Lines: Combination slitting lines are versatile machines that can handle a range of materials and can perform both slitting and cut-to-length operations. These lines are ideal for smaller manufacturers or those who require flexibility in their production process. Overall, the type of steel coil slitting line used will depend on the specific requirements of the manufacturer, including the type of material being processed, the desired strip width, and the volume of production.

- Q: an 18k steel and gold, screw style bracelet how much would it be worth?

- Steel does not come in an 18k version and is worth only about $1.50/pound. 18k gold (.750 or 75% pure) is currently worth about $40.20/gram, based on the spot price of gold of $1,667/ounce at this moment.

- Q: This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- pl. be specific about the type of steel: (Steel is a metal alloy whose major component is iron, with carbon content between 0.02% and 1.7% by weight. Carbon is the most cost effective alloying material for iron, but many other alloying elements are also used.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and their distribution in the steel controls qualities such as the hardness, elasticity, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also more brittle. The maximum solubility of carbon in iron is 1.7% by weight, occurring at 1130° Celsius; higher concentrations of carbon or lower temperatures will produce cementite which will reduce the material's strength. Alloys with higher carbon content than this are known as cast iron because of their lower melting point.[1] Steel is also to be distinguished from wrought iron with little or no carbon, usually less than 0.035%. It is common today to talk about 'the iron and steel industry' as if it were a single thing; it is today, but historically they were separate products. Currently there are several classes of steels in which carbon is replaced with other alloying materials, and carbon, if present, is undesired. A more recent definition is that steels are iron-based alloys that can be plastically formed (pounded, rolled, etc.). Iron alloy phases : Austenite (γ-iron; hard) Bainite Martensite Cementite (iron carbide; Fe3C) Ferrite (α-iron; soft) Pearlite (88% ferrite, 12% cementite) Types of Steel : Plain-carbon steel (up to 2.1% carbon) Stainless steel (alloy with chromium) HSLA steel (high strength low alloy) Tool steel (very hard; heat-treated) Other Iron-based materials : Cast iron (2.1% carbon) Wrought iron (almost no carbon) Ductile iron)

- Q: can steel boil and turn into a gaseous state?? if so how hot does it have to be for it to boil

- hahah umm ya u could boil steel but prob not at your house hahah and the boiling point of a medium carbon steel to be around 3000K

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into long sections known as rails. These coils are first uncoiled and then heated, allowing them to be rolled and formed into the desired rail shape. The resulting rails are then cut to the required length and undergo further processes such as straightening and finishing to ensure their strength, durability, and suitability for use in railways.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws by being unwound and fed into a machine that cuts and shapes them into individual screw blanks. These blanks are then threaded and undergo various processes to create the final steel screws.

- Q: What are the benefits of using steel coils in the manufacturing of pipes?

- Using steel coils in the manufacturing of pipes has several advantages: 1. Strength and durability: Steel is renowned for its strength and durability, making it an ideal material for pipes. By utilizing steel coils, pipes are provided with a solid foundation, enabling them to withstand high-pressure applications and resist damage from external factors such as impact or corrosion. This strength and durability increase the lifespan of the pipes, reducing the need for frequent replacements. 2. Customizability: Steel coils offer a high degree of flexibility in terms of customization and design. They can be easily formed into various pipe shapes and sizes, allowing manufacturers to produce pipes that meet specific project requirements. This flexibility also allows for the production of seamless pipes, which have superior structural integrity and a reduced risk of leakage. 3. Excellent thermal conductivity: Steel possesses excellent thermal conductivity, meaning it efficiently transfers heat or cold. This property is essential for pipes used in industries such as oil and gas, where temperature control is crucial. By utilizing steel coils, pipes can effectively handle extreme temperatures, preventing any damage to the pipes or the substances flowing through them. 4. Cost-effectiveness: Steel coils can be produced in large quantities, resulting in economies of scale and lower production costs. This cost-effectiveness benefits both manufacturers and consumers, as it helps keep the overall cost of pipes down. Additionally, the durability of steel pipes reduces the need for frequent repairs or replacements, resulting in long-term cost savings. 5. Enhanced corrosion resistance: Steel coils can be coated with protective layers to enhance their resistance to corrosion. This corrosion resistance is vital in applications where pipes come into contact with corrosive substances or are exposed to harsh environmental conditions. By utilizing steel coils with appropriate coatings, manufacturers can ensure that their pipes have a longer lifespan and maintain their structural integrity even under challenging circumstances. In conclusion, the utilization of steel coils in pipe manufacturing provides numerous benefits, including strength, customizability, thermal resistance, cost-effectiveness, and corrosion resistance. These advantages make steel coils the preferred choice for many industries that rely on durable and efficient piping systems.

Send your message to us

Best Prepainted Galvanized steel Coil in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 32423 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords