Hot/Cold Rolled Steel Coil Chinese Supplier Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1.Commodity: hot rolled steel coil, SPHC.

2.Executive Standards: GB,ASTM,JIS,EN,IS

3.Delivery condition: hot rolled or annealed

4.Delivery time: within 30days after L/C or T/T deposit

5.Specification:

thickness 1-4mm

width 800-1600mm

6.Coil weight: 2.5-3mt

7.Packing method: bundled with steel strip

8.Payment terms: 100%L/C at sight or 30%T/T deposit +70%balance against B/L copy.

9.MOQ: 50mt for single size

10.Chemical compostion

| Steel Grade | C % | Mn % | Si % | S % | P % |

| Q235 | 0.12-0.22 | 0.30-0.60 | 0.30 Max. | 0.04 Max. | 0.04 Max. |

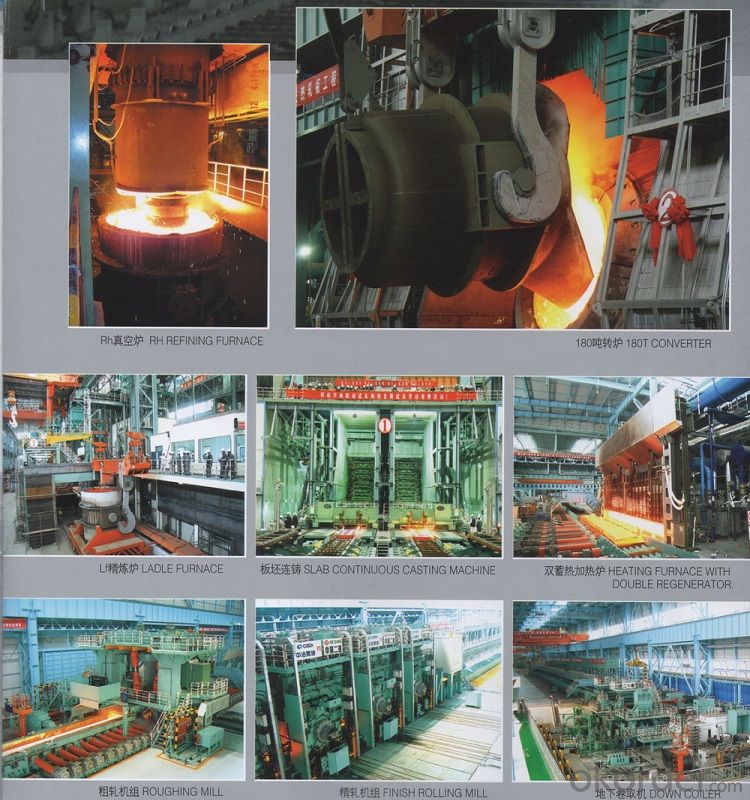

Product Image:

Production Process:

FAQ

1. Q: What's the MOQ?

A: Our MOQ is 25mt.

2. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

3. Q: What is the payment terms?

A: T/T, L/C at sight

4. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

5. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: What are the challenges in coil slitting for narrow strip widths?

- There are several challenges associated with coil slitting for narrow strip widths. One of the main challenges is maintaining accuracy and precision during the slitting process. When dealing with narrow strip widths, even the slightest misalignment or deviation can result in significant defects or inconsistencies in the final product. This requires careful calibration and adjustment of the slitting equipment to ensure that the strips are cut with utmost accuracy. Another challenge is the risk of material damage or deformation during the slitting process. Narrow strip widths are more prone to distortion, wrinkling, or edge cracking, especially if the material is not properly handled or supported during slitting. Special care must be taken to ensure that the material is fed smoothly through the slitting machine and that the tension is properly controlled to minimize any potential damage. Additionally, narrow strip widths can pose challenges in terms of handling and transporting the slit coils. These coils are more susceptible to bending, twisting, or telescoping, which can lead to difficulties in stacking, storage, or transportation. Proper packaging and handling techniques must be employed to ensure that the slit coils maintain their shape and integrity throughout the supply chain. Furthermore, narrow strip widths often require more frequent blade changes during the slitting process. This increases the complexity and time required for setup and maintenance, as the blades need to be carefully selected and replaced to achieve optimal cutting results. It is crucial to have skilled technicians who can handle these blade changes efficiently and effectively. Overall, while coil slitting for narrow strip widths offers various benefits such as cost savings and increased material utilization, it also presents several challenges that need to be carefully addressed. These challenges include maintaining accuracy, preventing material damage, ensuring proper handling and transportation, and managing blade changes effectively. By understanding and addressing these challenges, manufacturers can optimize their coil slitting operations and produce high-quality narrow strip products.

- Q: What is the role of steel coils in the production of industrial machinery?

- Steel coils play a crucial role in the production of industrial machinery as they are the primary raw material used to manufacture various components, such as structural frames, gears, shafts, and panels. These coils are processed and shaped into the desired forms through cutting, bending, and welding processes to create strong and durable machinery. The high strength and versatility of steel make it ideal for withstanding heavy loads, high temperatures, and harsh operating conditions, ensuring the reliability and performance of industrial machinery.

- Q: What are the main factors that affect the formability of steel coils?

- The main factors that affect the formability of steel coils include the steel's composition, mechanical properties, thickness, temperature, and lubrication.

- Q: I worked REALLY HARD basically begged my dad to let me stretch my ear lobe piercings. He finally said yes, as long as I don't pass 2g. c: So, we went to Hot Topic to buy tapers, but I don't know if I should get Steel or Acrylic tapers. Which ones are better to start off with?

- steel because they dont get that infected also they sre easier to put in. but they do get cold in the winter

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems as they are shaped and formed into various components such as pipes, tubes, and fittings. These coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the irrigation system.

- Q: How are steel coils straightened?

- Steel coils are straightened using a process called leveling. This involves passing the coils through a series of rollers that gradually flatten and align the steel, resulting in straightened coils.

- Q: I have a Victorinox Pioneer, and I recently filed a little metal off the blade for some jimping. Is the already stainless steel blade still stainless?

- Yes, stainless steel is stainless all the way through. All metals are uniform in composition throughout the piece. However, many metal items are plated to give a different finish from the base metal or to provide protection. An example is galvanized ductwork. The duct is made of steel, but a coating of zinc is plated onto it for corrosion resistance. Likewise, some items are made of steel or brass, but are chrome plated to present a bright, shiny appearance.

- Q: What are the different types of steel coil finishing tools?

- There are several types of steel coil finishing tools, including slitters, shears, levelers, and recoilers. These tools are used to cut, flatten, and rewind steel coils to achieve the desired shape and surface finish.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless steel can rust if placed in contact with some chemicals lik hypoclorite, bleach, or salt water. It depends on the type of stainless steel because there is not just a single stainless steel but a family of steel with different properties and corrosion resistance.

Send your message to us

Hot/Cold Rolled Steel Coil Chinese Supplier Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords