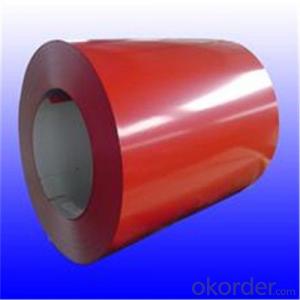

Prepainted galvanized Rolled Steel coil/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

- Q: Hello,is it possible to divide an alloy in its own elements? I am particularly interested in Stainless Steel, which is made of Nickel, Chrome and Iron. Do you have an idea of where can I find some more information (blogs, reviews, sites or books)?Thanks for your help

- Yes it is possible to recover individual elements from an alloy such as stainless steel, but not easy. Look up etching of stainless steel on google. This same etching solution will completely dissolve stainless steel. These solutions are strong acids such as H2SO4 and HNO3 so safety goggles and good ventilation are absolutely required. Once the metal has been dissolved, then you would need to use a qualitative analysis scheme to precipitate out the different metals one at a time as compounds, then do additional reactions to recover the metallic elements.

- Q: I am thinking about getting a cold steel tilite or a kershaw leek or possibly a buck sirus. If you have had any experience with these knives please give it to me. thanks

- Cold Steel uses an incredible quality of metal. If you want very durable go with that. The benefit to Kershaw is they make better folders. Fixed blade--go with Cold Steel. Folder, go with Kershaw. I get all my knives from the guys below, they have free shipping and really good prices.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It needs to be RED hot, the hotter the better. Yes you can use a camp fire if you put the file directly in the hottest part of the coals, but it'll take about 5-10 minutes to heat. Charcoal briquettes would probably work better as a heat source. You can use something like a blow dryer to intensify the coals, that might help. You'll also need a bench vice, and the biggest pair of pliers you can find, for leverage. Bending steel's not easy even when it's hot. You could also use a bit of steel pipe that'll fit over the end of the file. Stick the file in the vise when red-hot, slip the pipe over the free end, and use the pipe to bend it. OR, you could use the old-fashioned method of just holding it with pliers in one hand, and hitting it with a 5lb sledge hammer with the other. use something solid as an anvil, like a large steel pipe. you mighe be able to get away with using a small log, but you'll have to work twice as hard. Safety glasses are MANDITORY for this type of thing. Do not attempt without eye protection at all times. Ear plugs are also a very good idea.

- Q: I want to purchase steel for construction purpose, What aspects should I keep in mind while deciding that which company should I contact for this?

- It has been a few years since I was in the business but I have found that some steel from some countries can be quite different from the standards steel made in the US. For instance, one in 5 of my Indian made cast iron fittings would break when tightening it down. This never happened with US fittings. Even though I could take it back and get a refund, the increased price of US made materials was worth the savings in time and trouble. On a job in Columbia, the 3 inch angle iron came to us in 4 different sizes, all around three inches but not quite. This is not to say that all foreign metal is bad. One RD project I headed up we found a foreign bearing steel to be far superior to anything we could get in the states.

- Q: What are the advantages of using hot-rolled steel coils?

- Hot-rolled steel coils have several advantages. Firstly, they are produced at high temperatures, resulting in a more malleable and ductile material that can be easily shaped and formed. This makes hot-rolled steel coils ideal for a wide range of applications, such as construction, automotive, and machinery manufacturing. Additionally, the hot-rolling process enhances the mechanical properties of the steel, including increased strength and toughness. Moreover, hot-rolled steel coils have a lower cost compared to cold-rolled steel, making them a cost-effective choice for many industries.

- Q: I am a complete idiot when it comes to anything musical, so please forgive me if this is a stupid question. I bought my son his first guitar, acoustic and didnt realize until after I purchased it that it has steel strings. Can I have the strings changed from steel to nylon???

- Haha, You're too cute for me. Did you buy Alex the guitar? Just wait until your boys become the next Jonas Brothers :)

- Q: I need to construct a table with three columns, which states the name of the steel, its compositions (e.g. Fe and C), and its special properties for a variety of different steel products.Help me please, a site with info would be great, explanations would be even better.

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and form of their presence in the steel (solute elements, precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also less ductile. H.

- Q: Hey Guys, I'm planning on purchasing a bmx bike and I have been recommended by many people the Kink Launch 2012. I'm thinking of getting it but the frame is made from High Tensile steel and I know the chromoly is stronger and more expensive, but I plan to use my bmx just to chill, ride with friends and some times go through dirt trails at my park, I would like to know, how strong Hi Tensile steel is and can it handle jumps not massive jumps but like jumps where you get like 3 feet high (1m) just for fun, I might go to the skate park but I'm not gonna do tail whips and massive jumps, I just want it as a mobile piece of transportation. I don't want to buy a mtb because I already had 3 of them and they are not practical to take with you on holidays.So, do you think the Kink Launch 2012 is good enough or should I cough up an extra $80 and get the gap ($500 AU)? As I said I ain't gonna do huge jumps.

- High tensile steel could mean almost anything. SAE 4130 Chrome-Moly steel is the de-facto standard for steel bikes frames. High tensile steel could actually mean the same thing since chrome-moly is classified as high strength steel. The strength of the frame depends as much on the quality of the welds and on the size/thickness of the tubing as much as anything else. I'd say what kind of steel you use makes only a minor difference. One reason you want to buy bikes from reputable name-brand companies is they tend to have strict quality controls, this is particularly important when it comes to welds. Welds are always the weakest part of any bike frame, don't let anyone tell you different. 99% of the time if something in the frame breaks, it'll be at the welds. hope this helps.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

- Q: Can steel coils be used in the production of automotive parts?

- Yes, steel coils can be used in the production of automotive parts. Steel coils are often used in the manufacturing process of various automotive components such as body panels, frames, chassis, suspension parts, and engine parts. The steel coils are typically processed through various methods such as cutting, stamping, bending, and welding to shape them into the desired automotive parts. Steel is a preferred material for automotive parts due to its strength, durability, and resistance to corrosion. Moreover, steel coils are available in different grades and thicknesses, allowing manufacturers to tailor the material properties to meet specific requirements for different automotive applications. Overall, steel coils play a critical role in the production of automotive parts, contributing to the performance, safety, and longevity of vehicles.

Send your message to us

Prepainted galvanized Rolled Steel coil/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords