Prepainted Galvanized rolled Steel coil/Sheet from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

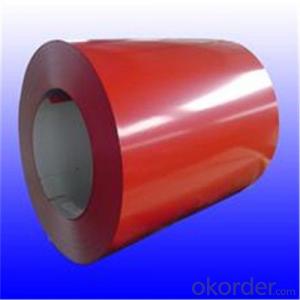

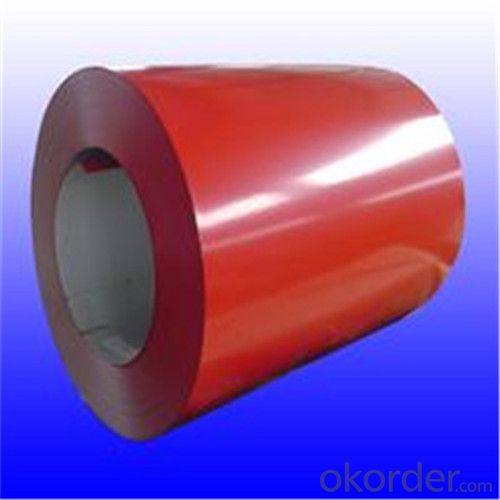

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Characteristic of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

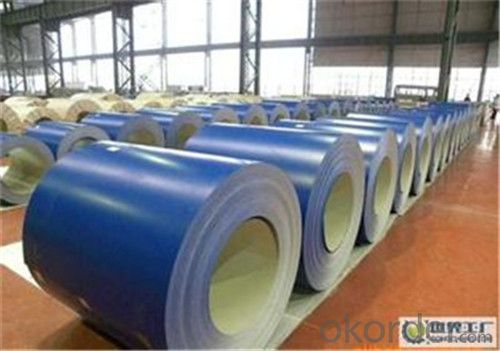

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

50MT, it is for one container.

2.Whether your company have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the

- Q: How are steel coils used in the manufacturing of storage shelves?

- Steel coils are used in the manufacturing of storage shelves by being formed and shaped into the desired dimensions and designs. These coils are often cut, bent, and welded to create the frame and shelves of the storage unit. The strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of the shelves.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel coils in various sectors such as automotive, construction, and manufacturing is a significant driver. Additionally, the expanding infrastructure projects and urbanization in emerging economies contribute to the growth of the industry. Moreover, technological advancements in steel manufacturing processes and the adoption of efficient production techniques also play a crucial role in driving the growth of the steel coil industry.

- Q: Steel seems to be much less expensive. What is the reason why? I've heard steel will ruin a barrel after time....is that true? But with the price difference maybe it don't matter? Is steel reliable? What are the negatives about steel I should know before buying?

- Steel is a far more common thus cheaper metal than brass which is made of copper and zinc. The steel case stays in the firing chamber so does not do a thing to the barrel. It does have a different coefficient of expansion and when the gun gets hot it could jam in the chamber more than brass. Some of the steel has a lacquer coating on it that could gum up the works. The biggest disadvantage with steel is that as it is worked it gets weaker so reloading it is not real practical as you will get a lot of blown cases and head separations. In the long run you come out ahead buying brass and reloading than you do buying steel and throwing it away.

- Q: Can steel coils be customized in terms of size and thickness?

- Yes, steel coils can be customized in terms of size and thickness. Manufacturers have the capability to produce steel coils in various sizes and thicknesses to meet the specific requirements of different industries and applications.

- Q: How are steel coils used in the production of metal cabinets?

- Steel coils are used in the production of metal cabinets as they serve as the primary raw material. These coils are unwound and cut into precise lengths, which are then formed, shaped, and welded to create the various components of the cabinet, such as the sides, back, and shelves. The steel coils provide the necessary strength, durability, and rigidity required for the construction of sturdy and long-lasting metal cabinets.

- Q: How are steel coils inspected for thickness using ultrasonic testing?

- Ultrasonic testing is employed to inspect the thickness of steel coils, utilizing a non-destructive method. When conducting this process, a handheld ultrasonic thickness gauge is utilized to determine the thickness of the coil. The ultrasonic thickness gauge emits high-frequency sound waves that travel through the steel coil. These sound waves rebound from the opposite side of the coil, generating an echo. The time it takes for the echo to return to the gauge is measured and utilized to compute the coil's thickness. The gauge comprises a transducer responsible for emitting the sound waves and a receiver that detects the echoes. To ensure optimal acoustic contact between the transducer and the steel surface, the transducer is placed on the coil's surface, utilizing a coupling gel or oil. The transducer releases a brief burst of sound waves, which penetrate through the steel coil and reach the opposite side. If the sound waves encounter any variations or defects in the coil's thickness, they reflect back to the transducer. These echoes are detected by the receiver, and the time between the emission and reception of the sound waves is measured. By utilizing the known speed of sound in steel, the time taken for the sound waves to traverse the coil and return can be converted into a thickness measurement. This enables an accurate evaluation of the steel coil's thickness at different points. Ultrasonic testing is a dependable and efficient method for inspecting the thickness of steel coils. It permits swift measurements without causing any harm to the material, thereby making it ideal for quality control purposes and ensuring compliance with manufacturing specifications.

- Q: How are steel coils used in the production of steel washers?

- Steel coils are used in the production of steel washers as they are unwound, flattened, and cut into smaller pieces to create the raw material for manufacturing washers.

- Q: What are the different methods of coil edge trimming?

- There are several methods of coil edge trimming, including shearing, slitting, and laser cutting. Shearing involves cutting the edges of the coil using a large blade or shear. Slitting involves making multiple cuts along the coil's edges using a slitting machine equipped with circular blades. Laser cutting uses a high-powered laser beam to precisely cut the coil's edges. Each method has its own advantages and is chosen based on factors such as the material being trimmed and the desired precision of the cut.

- Q: What are the different methods of coating steel coils?

- There are several different methods of coating steel coils, each offering unique benefits and applications. Some of the most common methods include: 1. Hot-dip galvanizing: This process involves immersing the steel coils in a bath of molten zinc. The zinc forms a protective layer on the surface of the steel, providing excellent corrosion resistance and durability. 2. Electro-galvanizing: In this method, a layer of zinc is applied to the steel coils using an electroplating process. It provides similar corrosion resistance to hot-dip galvanizing but with a thinner coating. 3. Electro-coating (E-coating): Also known as electrodeposition, this method involves immersing the steel coils in a bath of paint or resin containing electrically charged particles. An electrical current is applied, causing the particles to adhere to the surface of the steel. E-coating provides excellent corrosion protection and is often used as a primer before applying additional coatings. 4. Powder coating: Steel coils can be coated with a dry powder paint that is electrostatically charged and then baked onto the surface. This method offers a wide range of colors, finishes, and textures, providing both aesthetic appeal and corrosion resistance. 5. Organic coatings: These coatings, such as paints or lacquers, are applied to the steel coils using various techniques like spray, roller, or dip coating. Organic coatings provide protection against corrosion, as well as offering customizable colors and finishes. Each method of coating steel coils has its advantages and is selected based on the desired level of corrosion resistance, appearance, and specific end-use requirements.

- Q: I want to make a stock removal knife, but I am really confused about what steel to use. I am just a beginner but I read o1 steel is great? Also I am kind of on a budget.

- 01 tool steel is easier to work with. You need to contact places like Pop Knives and Supplies out of Washington, Georgia or Sheffield Steel out of Florida, I made custom knives for years with my husband. Made alot with ATS-34 Stainless. Look at links on my website source.

Send your message to us

Prepainted Galvanized rolled Steel coil/Sheet from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords