Prepainted Galvanized Steel Coil Matt- Low Price ASTM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized Steel Coil Matt- Low Price ASTM:

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized Steel Coil Matt- Low Price ASTM:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

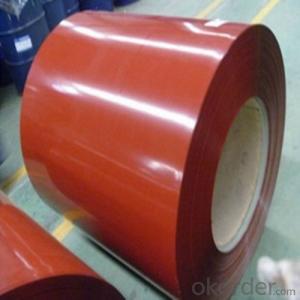

3.Prepainted Galvanized Steel Coil Matt- Low Price ASTM Images

4.Prepainted Galvanized Steel Coil Matt- Low Price ASTM Specification

Standard:ASTM

Grade: CS

Thickness: 0.15mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized Steel Coil Matt- Low Price ASTM

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your moq

Normally our moq is 12mt per size ,but it is up to different size.

- Q: Why does steel with several composites have a greater hardenability from quenching than low carbon steel alloys?Any help would be great

- Bit tricky to explain and I don't know muh about it but steel on its own has lost of gaps in it ( the molecular structure) and when carbon is added thos gaps are filled, I think of it like this: it is easier to punch through expanded polystyrene( with all the little balls) than unexpanded(just a lump of plastic) as the balls are not properly joined and have air pockets between them.

- Q: What are the challenges in coil leveling for coated steel?

- Coil leveling for coated steel presents several challenges that need to be addressed in order to achieve high-quality, flat, and smooth coils. Firstly, one of the main challenges is the potential for coating damage during the leveling process. Coated steel coils are typically coated with materials such as zinc or paint, which can be easily scratched or marred if not handled properly. The leveling process involves passing the coil through a set of leveling rolls, which can potentially cause friction, abrasion, or other mechanical damage to the coating. Therefore, it is crucial to carefully control the speed, pressure, and alignment of the leveling rolls to minimize coating damage. Secondly, the thickness variation across the coil presents a significant challenge. Coated steel coils often have thickness variations due to inherent material properties or production processes. These variations can result in uneven leveling and can lead to coils with waviness or uneven flatness. Achieving uniform leveling across the entire coil surface is essential to ensure consistent quality and appearance of the final product. Another challenge in coil leveling for coated steel is the possibility of coil shape distortion. Coating processes can introduce stresses into the steel, which can cause the coil to warp or distort during the leveling process. This distortion can result in coils with uneven edges or inconsistent flatness. Proper control of the leveling process parameters, such as the number of leveling passes and the tension applied to the coil, is necessary to minimize shape distortion. Additionally, the coil leveling process can generate internal stresses in the steel itself, particularly in coated steels that have been cold-rolled or heat-treated. These internal stresses can cause coil spring-back, where the coil tries to return to its original shape after leveling. Spring-back can result in coils with unwanted curvature or uneven flatness. Effective strategies, such as stress relief annealing or using counteracting leveling techniques, are essential to minimize spring-back and achieve the desired flatness. Finally, the handling and storage of coated steel coils present challenges in maintaining the quality of the leveled coils. Coated steel coils are sensitive to environmental conditions such as humidity, temperature, and exposure to corrosive agents. Proper storage and handling practices are crucial to prevent coating damage, rust, or other forms of deterioration that can occur during transportation or storage. In summary, the challenges in coil leveling for coated steel include minimizing coating damage, addressing thickness variation, controlling shape distortion and spring-back, and ensuring proper handling and storage. Overcoming these challenges requires precise control of process parameters, the use of appropriate leveling techniques, and adherence to strict quality control measures throughout the entire process.

- Q: How do steel coils contribute to the HVACR equipment industry?

- Efficient heat transfer and effective functioning of HVACR systems are crucial roles played by steel coils in the HVACR equipment industry. These coils, made of high-quality steel, are integral components of air conditioners, heat pumps, refrigerators, and boilers. Facilitating heat transfer is one of the primary functions of steel coils in HVACR equipment. Designed to efficiently transfer heat between the refrigerant and the surrounding air or water, these coils utilize a large surface area and good thermal conductivity. As a result, HVACR equipment can effectively cool or heat a given space, ensuring optimal energy efficiency and reducing operating costs in residential and commercial applications. In addition to heat transfer, steel coils contribute to the overall durability and longevity of HVACR equipment. The use of corrosion-resistant steel in these coils helps prevent damage from moisture and other environmental factors. This reliability is particularly important as HVACR systems often face harsh conditions and must operate continuously to maintain comfortable indoor environments. Furthermore, steel coils offer versatility and customization options to meet specific HVACR requirements. Manufacturers can vary the size, shape, and configuration of the coils to fit available space and optimize performance. This flexibility enables efficient integration of steel coils into different HVACR equipment, ensuring they meet the specific heating and cooling needs of diverse environments. In conclusion, steel coils are indispensable in the HVACR equipment industry. They enable efficient heat transfer, enhance durability, and offer customization options, ensuring effective functioning and energy efficiency of HVACR systems. Manufacturers can provide reliable and long-lasting solutions for heating, ventilation, air conditioning, and refrigeration needs in residential and commercial settings by incorporating high-quality steel coils into their products.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are processed for cutting to length or blanking through a series of steps. First, the coil is uncoiled and flattened to remove any inherent deformities. Then, the edges are trimmed to ensure uniform width and straightness. Next, the coil is fed into a leveling machine to eliminate any remaining inconsistencies in thickness. Once leveled, the steel is conveyed to a cutting machine where it is precisely cut into individual sheets of desired length or blanks. These sheets or blanks are then stacked and prepared for further fabrication or distribution.

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- Surgical Earrings

- Q: They say it's some six times stronger than steel. need some explanation.

- Lol I dont know where you heard that, there probably saying for small insects like for instence a small instect in a spider web is like us( humans ) in steel but no I could break through a web with my soft hair or finger, like not an ant because there extremely strong but like a flea

- Q: How are steel coils inspected for elongation?

- Steel coils are inspected for elongation using a variety of methods. One common method is the use of a tensile testing machine. In this method, a small sample is taken from the steel coil and placed into the machine. The machine then applies a pulling force to the sample until it breaks. The amount of force required to break the sample is measured, and this information is used to determine the elongation of the steel coil. Another method used to inspect steel coils for elongation is the use of ultrasonic testing. In this method, high-frequency sound waves are passed through the steel coil. By analyzing the reflection of these sound waves, it is possible to determine the elongation and other properties of the steel coil. Visual inspection is also an important aspect of inspecting steel coils for elongation. Trained technicians visually inspect the steel coils for any signs of stretching or deformation that may indicate excessive elongation. Overall, a combination of mechanical testing, ultrasonic testing, and visual inspection is used to thoroughly inspect steel coils for elongation and ensure their quality and compliance with industry standards.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Rust is the process of steel oxidizing when in contact with oxygen, this reaction can be much fast if certain components are present, such as wet air or water. However, if the paint completely isolates the steel from the environment, the encompassed steel will never rust as long as paint shields it. Aluminum corrodes but it does not rust. Rust refers only to iron and steel corrosion. Aluminum is actually very prone to corrosion. However, aluminum corrosion is aluminum oxide, a very hard material that actually protects the aluminum from further corrosion. Aluminum oxide corrosion also looks a lot more like aluminum, so it isn't as easy to notice as rusted iron.

- Q: What is the current value of steel? Is it expected to increase in value?

- They'd never be worth much for their steel content, likely always less than face value. They might be worth a premium as coins, but not anything you'd call an investment.

Send your message to us

Prepainted Galvanized Steel Coil Matt- Low Price ASTM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords