Pre-painted Galvanized Steel Coil Used for Industry with Our Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coil Used for Industry

1.Structure of Pre-painted Galvanized Steel Coil Description

With GI as base metal, after pretreatement and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Painting steel isthe product based on the metal sheet, of which surface is finally installed ofthe plastic film(PVC, PE) IN addition to being firstly covered with the coatingand printed ink in. The coated layer of painting steel plate consists of chemicaland filming layer, primer coated layer, pattern printed layer and surfacecoated layer. The top and back coating shall generally be the weatherproofpaint, as well can be the application of the paint with special capabilitiessuch as stain-resistant, self cleaning capability, high thermal resistance,antistatic capability, sterilizing capability, finger-print prevention and etc.

With GI(aluzinc) asbase metal, after pretreatement(degrease and chemical treatment)and liquid dopewith several layers of color, then after firing and cooling, finally the platesteel is called pre-painted galvanized (aluzinc)steel. Pre-painted galvanized steelis good capable of decoration, molding, corrosion resistance. It generallydisplays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

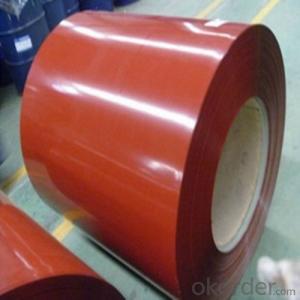

3. Pre-painted Galvanized Steel Coil Images

4. Pre-painted Galvanized Steel Coil Specification

Pre-painted Galvanized Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-275g/㎡

|

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How do steel coils contribute to fire resistance in buildings?

- Steel coils contribute to fire resistance in buildings in several ways. Firstly, steel coils have high melting points, which means they can withstand extremely high temperatures without losing their structural integrity. This helps prevent the collapse of the building during a fire. Additionally, steel coils have low thermal conductivity, meaning they do not readily transfer heat. This property helps to contain the spread of fire, preventing it from spreading rapidly within the building. Moreover, steel coils can be used to reinforce concrete structures, enhancing their fire resistance. By providing strength and stability to the building, steel coils play a crucial role in ensuring the overall fire safety of the structure.

- Q: I was just thinking, is their a way to make steel qualities inherent in concrete, therefore eliminating the need for re bar?

- Mixing hot steel with liquid concrete would be very hazardous to your health. Steal in a molten state would flash the water in the concrete mix into steam and the steam would blow concrete and steel out of your mold. This would be about like being shot with a shotgun. This occurred in a steel mill near me some years ago on a rainy day when some steel splashed from a ladle and landed on a puddle of water, part of the siding was blown off the building and one worker sent to the hospital.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment as they are typically shaped and welded to create various components such as pipes, tanks, and pressure vessels. These coils provide a strong and durable foundation for the equipment, ensuring it can withstand the harsh conditions and high pressures associated with oil and gas extraction and processing.

- Q: How are steel coils inspected for impact resistance using impact testers?

- To assess the impact resistance of steel coils, specialized machines called impact testers are utilized. These machines are designed to evaluate the coils' ability to endure impacts. The process involves subjecting the coils to controlled impacts and measuring the resulting deformation or damage. Initially, the steel coils are securely positioned and oriented on the impact tester. This ensures accuracy and consistency. The tester is equipped with a striking element, like a pendulum or falling weight, which applies a specific force upon impact. The element is aligned precisely with the steel coil for precise testing. Once the setup is complete, the impact tester is activated, and the striking element is released to impact the steel coil. The force of the impact is carefully controlled and measured to ensure consistency across multiple tests. The tester records various parameters, including applied force and impact duration. After the impact, the steel coil undergoes a thorough examination for visible deformation or damage. This includes checking for dents, cracks, or any signs of structural compromise. The extent of the deformation or damage is recorded and compared to predetermined acceptance criteria to determine if the coil passes or fails the impact resistance test. To gather additional data during testing, impact testers can be equipped with various sensors and cameras. High-speed cameras capture the impact in slow motion, allowing for detailed analysis of the coil's behavior. Strain gauges can also be attached to the steel coil to measure strain and stress experienced during the impact. In conclusion, the use of impact testers offers a reliable and standardized method for inspecting the impact resistance of steel coils. By subjecting the coils to controlled impacts and accurately measuring deformation or damage, manufacturers can ensure that their steel coils meet the required impact resistance standards for different applications.

- Q: I'm writing a book, and there is a part where there is a death arena with a white-hot river of steel. How hot would that be?

- This Site Might Help You. RE: how hot is white hot steel? I'm writing a book, and there is a part where there is a death arena with a white-hot river of steel. How hot would that be?

- Q: What are the different methods of coil blanking for irregular shapes?

- Coil blanking for irregular shapes can be achieved through various methods. Among these methods, one commonly employed technique is laser blanking. By utilizing a high-powered laser, the shape is directly cut from the coil with exceptional precision. This method proves especially effective for intricate shapes, minimizing wastage. Another approach is water jet blanking, where a forceful stream of water mixed with abrasive particles is employed to cut the shape from the coil. Water jet blanking is particularly suitable for thicker materials or situations where heat sensitivity is a concern. Additionally, die blanking involves the utilization of a die to stamp out the desired shape from the coil. This method is frequently applied in large-scale production runs and can be automated for improved efficiency. Lastly, plasma blanking utilizes a plasma torch to cut the shape from the coil. It is commonly employed for thicker materials or situations requiring high cutting speeds. The choice of coil blanking method for irregular shapes is dependent on factors such as material thickness, shape complexity, production volume, and desired precision. Each method possesses its own advantages and limitations, necessitating careful selection to achieve optimal results.

- Q: it has 2 be 20 inches overall, and 2and1/2 inches wide and .25 or more inches thick... im thinking truck steel but im not sure thx

- What is the purpose of the knife? What properties do you want? Strength, flexibility, ability to hold an edge, ability to make razor sharp, ease to sharpen, resistance to corrosion, cost? What method are you going to use to make the blade? Cast, forge and hammer, multiple folds? Are you going to be a stabbing knife, a slicing knife, chopping knife, or just a pretty show knife? What is truck steel? Doesn't sound like it would be very good blade steel.

- Q: Can steel coils be used in the food processing industry?

- Yes, steel coils can be used in the food processing industry. Steel coils are often used to manufacture a wide range of food processing equipment such as conveyor belts, food storage tanks, mixing tanks, and processing machinery. Steel is a durable and hygienic material that is resistant to corrosion, making it suitable for use in food processing environments. Additionally, steel coils can be easily cleaned and sanitized, ensuring the safety and cleanliness of the food processing equipment. Overall, steel coils are a commonly used material in the food processing industry due to their strength, durability, and compatibility with food safety standards.

- Q: How are steel coils used in the manufacturing of marine equipment?

- Steel coils are used in the manufacturing of marine equipment as they serve as a primary material for constructing various components such as hulls, decks, and superstructures. The coils are shaped, cut, and formed into the desired shapes and sizes to create strong and durable structures that can withstand the harsh conditions of the marine environment. Additionally, steel coils are also used in the fabrication of marine machinery and equipment, including engines, propellers, and winches, due to their high strength and corrosion resistance properties.

- Q: What are the different types of steel coil packaging methods?

- There are several types of steel coil packaging methods, including shrink wrapping, strapping, wooden crates, and steel or plastic bands.

Send your message to us

Pre-painted Galvanized Steel Coil Used for Industry with Our Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords