Pre-painted Galvanized Steel Coil Used for Industry with Our Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coil Used for Industry

1.Structure of Pre-painted Galvanized Steel Coil Description

With GI as base metal, after pretreatement and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

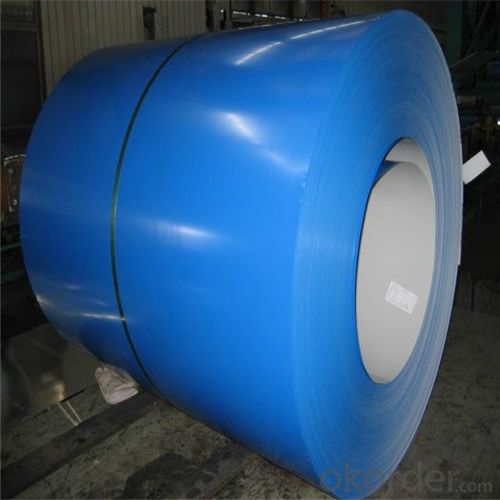

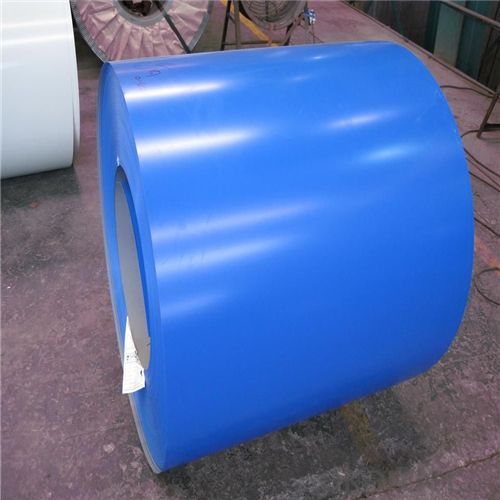

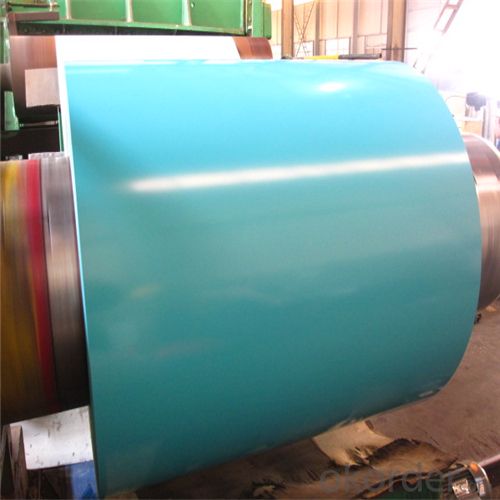

3. Pre-painted Galvanized Steel Coil Images

4. Pre-painted Galvanized Steel Coil Specification

Pre-painted Galvanized Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-275g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

We can supply customers' with different specifications of the highest quality and lowest price.

Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied ,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit.

We are waiting for your email.

- Q: How is steel sustainable as a building material?How is wood sustainable as a building material?

- Wood as it comes from trees which are in nature.

- Q: Procedures for sharpening a knife with the stone and the steel?

- If you are lucky and have a whet stone block you need some patience water or light machine oil. Take your time and work in circular motion at a slight angle as to put an edge where you want it. I tend to think of it like polishing and work the length of the blade. If you work with a steel you are suppose to pull the blade across the steel at an angle. I have forgotten the angle but if you attempt this you soon find that you can associate a certain feel of the way the blade crosses the steel and know when you have it right and check the blade periodically until you have it the way you want it. There are some other sharpeners out there where you just draw the blade thru a device and they work as well. I was taught the old ways with the stone and the steel and don't know the actual prescribed angles but can tell you that you will be able to eye ball the angle and you don't have to use heavy pressure. These processes won't work on a serrated blade!

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: How are steel coils welded together?

- Steel coils can be welded together using various methods, depending on the specific requirements and the type of steel being used. One common method is the use of electric resistance welding (ERW), where an electric current is passed through the steel coils to generate heat. This heat melts the edges of the coils, and pressure is applied to join them together. ERW is a quick and cost-effective method for welding steel coils. Another method is high-frequency induction welding (HFIW), which is commonly used for thinner steel coils. In this process, an induction coil is used to generate an alternating magnetic field, which induces an electric current in the steel coils. The resistance of the coils to this electric current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is often employed. This method involves the use of a granular flux and a continuous electrode, which is fed into the weld area. The flux melts, creating a protective shield for the weld pool, and the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. Additionally, laser welding and gas metal arc welding (GMAW) can also be used to weld steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, uses an electric arc between a consumable wire electrode and the steel coils to create a weld. Regardless of the welding method used, the key factors for successful welding of steel coils are proper preparation of the edges, maintaining the appropriate heat and pressure levels, and ensuring the correct welding technique is employed.

- Q: How are steel coils used in the manufacturing of building materials?

- Due to their strength, durability, and versatility, steel coils find wide application in the production of building materials. Typically, these coils are made from high-quality steel and shaped into a continuous, flat strip. One of the primary uses of steel coils in building materials involves manufacturing steel roofing and siding. To achieve the desired dimensions and profiles, the coils undergo a series of processes that involve cutting, shaping, and rolling the steel. Consequently, the resulting roofing and siding materials are highly durable and resistant to weather, enabling the construction of long-lasting building envelopes. Additionally, steel coils are essential in the production of steel studs, which are crucial components for constructing frameworks. By cutting and forming the coils into precise shapes, they are assembled to create sturdy and rigid frameworks for walls, ceilings, and other structural elements. Notably, steel studs offer various advantages such as a high strength-to-weight ratio, fire resistance, and dimensional stability, making them a popular choice within the construction industry. Apart from roofing, siding, and framing, steel coils are utilized in the manufacturing of various other building materials. These materials encompass steel pipes, beams, columns, and reinforcement bars, which are indispensable for constructing foundations, infrastructure, and structural elements. Furthermore, steel coils serve as raw materials for fabricating metal panels, doors, windows, and other architectural components. In summary, steel coils play an indispensable role in manufacturing building materials due to their provision of necessary strength and durability for robust and long-lasting structures. Their versatility enables the production of a wide range of building components, cementing steel coils as an invaluable resource within the construction industry.

- Q: Are steel coils used in construction?

- Yes, steel coils are commonly used in construction. They are often used in the manufacturing of structural components, such as beams, columns, and trusses, as well as in the construction of metal buildings and infrastructure projects. Steel coils provide strength, durability, and versatility to various construction applications.

- Q: What are the dimensions of steel coils used in the metalworking tool industry?

- The dimensions of steel coils used in the metalworking tool industry can vary depending on the specific application and requirements of the tool being used. However, there are some common dimensions that are often seen in the industry. Typically, steel coils used in metalworking tools are available in various widths ranging from 24 inches to 72 inches. The thickness of the coils can vary as well, with common thicknesses ranging from 0.020 inches to 0.250 inches. The length of the coils can vary significantly, with standard lengths typically ranging from 100 feet to 2000 feet or more. These dimensions are chosen based on factors such as the type of metal being worked, the specific tool being used, and the desired outcome of the metalworking process. Additionally, other factors such as the weight and handling capabilities of the tool and the efficiency of the manufacturing process may also influence the dimensions of the steel coils used. It is crucial to consult with manufacturers, suppliers, or industry experts to determine the most suitable dimensions for steel coils in the metalworking tool industry, as these dimensions can vary based on specific needs and preferences.

- Q: How are steel coils used in the manufacturing of marine equipment?

- Steel coils are used in the manufacturing of marine equipment as they serve as a primary material for constructing various components such as hulls, decks, and superstructures. The coils are shaped, cut, and formed into the desired shapes and sizes to create strong and durable structures that can withstand the harsh conditions of the marine environment. Additionally, steel coils are also used in the fabrication of marine machinery and equipment, including engines, propellers, and winches, due to their high strength and corrosion resistance properties.

- Q: i want to know what is light gauge steel and the diffrences between light gauge steel and steel for roof truss.

- as a welder i can answere this. wel i think i can after 2 years of classes. so...light guage steel usually referes to the THICKNESS of the metal. also known as SHEET METAL. the only diffrences between light guage and roof truss is that a truss will be thicker metal ex- an i-beam for a structure is usually 1/2inch or 3/8 for smaller buildings. also there is no such thing as light weight steel. steel is steel the only thing that determins its weight is its size/thickness aluminum is a whole nother ballgame. ever see a pound of aluminum vs. a pound of steel? aluminum can be 1/2 or less the weight of steel. but its tensile strength suffers EX. say steel will snap at 70,000 pounds, aluminum will snap at 40,000 pounds, if it even snaps that is! it just tends to bend like rubber. aluminum is handy for many things because it will not rust.

- Q: earlier name of jsw steel ltd. may be jindal iron steel ltd.

- JSW Steel Ltd - Profile Office Address 5 A, Jindal Mansion, Dr A G Deshmukh Marg, Mumbai Maharastra 400026 Phone 022-23513000 Business Summary JSW Steel Limited Formerly known as Jindal Vijayanagar Steel Limited. The Company's principal activity is to manufacture hot rolled steel coils in India using the revolutionary Corex technology. In addition, the Company also manufactures steel plates and sheets. It manufactures steel using oxygen based iron and steel through continuous casting and hot rolling. Executive Team Executive Name Designation Savitri Devi Jindal Sajjan Jindal Dr. B N Singh Chairperson Additional Director Vice Chairman Managing Director Joint Managing Director

Send your message to us

Pre-painted Galvanized Steel Coil Used for Industry with Our Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords