Prepainted Galvanized corrugated Plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.material :

galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness :

normal use 0.3-0.6mm

3.length:

any length,according to the transportation,generally less than 12m

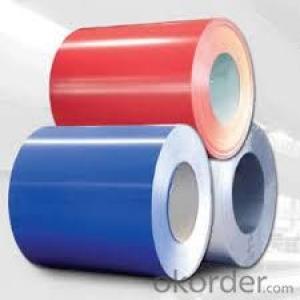

4.color:

standard color:red,blue,white,grey

special color:according to RAL color

Specification:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length,according to the transportation,generally less than 12m |

color | standard color:red,blue,white,grey |

special color:according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span:more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house,steel house,mobile house,modular house,villa,bungalow design,portable house/carbin,ready made house,kiosk booths,steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts,maufacturing shells of motors and so on | |

packing | plastic film,pallet or as your request |

Images:

- Q: What are the different surface textures for pre-painted steel sheets?

- There are several different surface textures for pre-painted steel sheets, including smooth, matte, textured, embossed, and patterned.

- Q: What is the typical weight of steel sheets?

- The typical weight of steel sheets varies depending on their size, thickness, and type of steel being used. Generally, steel sheets can range in weight from a few pounds to several tons. For example, a standard 4x8 foot steel sheet with a thickness of 1/4 inch can weigh around 110 pounds, while a larger 10x10 foot sheet with a thickness of 1 inch can weigh over 1,000 pounds. It is important to note that these are just general estimates, and the weight can vary based on specific factors such as the alloy composition or any additional coatings applied to the steel sheets.

- Q: Can steel sheets be used for automotive suspension components?

- Yes, steel sheets can be used for automotive suspension components. Steel offers high strength and durability, making it a suitable material for the suspension system, which withstands significant loads and impacts. Steel sheets can be shaped and formed into various suspension components such as control arms, springs, and stabilizer bars, providing the necessary structural support and stability required for a vehicle's suspension system.

- Q: What are the different manufacturing processes for steel sheets?

- There are several manufacturing processes for steel sheets, including hot rolling, cold rolling, and electro-galvanizing. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through rollers to achieve the desired thickness and shape. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature to further refine its thickness and surface finish. Electro-galvanizing is a process where a layer of zinc is electroplated onto the steel sheet to provide corrosion resistance. Other processes such as pickling, annealing, and coating may also be involved in the manufacturing of steel sheets.

- Q: What is the difference between a galvalume and galvanized steel sheet?

- The main difference between a galvalume and galvanized steel sheet lies in the coating applied to the steel surface. Galvalume steel sheets are coated with an aluminum-zinc alloy, while galvanized steel sheets are coated with zinc. The coating on galvalume steel sheets provides superior corrosion resistance compared to galvanized steel sheets. The combination of aluminum and zinc creates a protective barrier that helps prevent rusting and corrosion, even in harsh environments. Additionally, galvalume steel sheets have better heat reflectivity than galvanized steel sheets. This makes them more energy-efficient in hot climates as they reflect a larger portion of the sun's heat, reducing cooling costs. Furthermore, galvalume steel sheets have better resistance to scratches and fingerprints due to their unique coating composition. This makes them more visually appealing and easier to maintain compared to galvanized steel sheets. In terms of price, galvalume steel sheets are generally more expensive than galvanized steel sheets due to the added benefits and higher quality of the coating. However, the long-term cost-effectiveness of galvalume steel sheets can outweigh the initial higher purchase price. Overall, while both galvalume and galvanized steel sheets offer some level of protection against corrosion, galvalume steel sheets provide superior corrosion resistance, heat reflectivity, and aesthetic appeal. Therefore, the choice between the two depends on the specific requirements of the project and the environmental conditions the steel sheet will be exposed to.

- Q: Are the steel sheets corrosion-resistant?

- Depending on the steel type and the applied protective coating, steel sheets can exhibit corrosion resistance. Stainless steel sheets, for instance, possess outstanding corrosion resistance due to the presence of chromium, forming a passive protective layer on the surface. Furthermore, galvanized steel sheets are coated with zinc, serving as a sacrificial barrier to safeguard the underlying steel against corrosion. Coatings like painting, powder coating, or plating can also render other types of steel sheets corrosion-resistant. Thus, it becomes crucial to consider the specific steel type and any additional protective measures implemented in order to assess the corrosion resistance of steel sheets.

- Q: Can steel sheets be bent or curved?

- Yes, steel sheets can be bent or curved. Steel is a malleable material, meaning it can be easily shaped or formed without breaking or cracking. This property allows steel sheets to be bent or curved into various shapes and angles, depending on the desired outcome. The process of bending or curving steel sheets typically involves the use of specialized tools such as press brakes or rollers. These tools apply force to the steel sheet, causing it to bend or curve according to the desired specifications. This ability to manipulate steel sheets makes them highly versatile and widely used in industries such as construction, automotive, and manufacturing.

- Q: What are the different thicknesses available for steel sheets?

- Steel sheets are available in various thicknesses, ranging from thin gauges of around 0.4mm to thick gauges of up to 25mm or more, depending on the specific application requirements.

- Q: What are the different certification standards for steel sheets?

- There are various certification standards for steel sheets, including ISO 9001 which ensures quality management systems, ISO 14001 which focuses on environmental management systems, and ASTM A568/A568M which specifies the general requirements for steel sheet products. Additionally, there are standards such as ASTM A653/A653M for hot-dip galvanized steel sheets and ASTM A1008/A1008M for cold-rolled steel sheets. These standards help ensure the quality, performance, and compliance of steel sheets in different applications.

- Q: What are the applications of steel sheets in construction?

- Due to their exceptional strength, durability, and versatility, steel sheets find a wide range of applications in the construction industry. Some of the key uses of steel sheets in construction are: 1. Roofing and cladding: Steel sheets are commonly employed in both residential and commercial buildings for roofing and cladding purposes. They offer a long-lasting and weather-resistant solution, safeguarding the structure against the elements. 2. Structural components: Steel sheets are utilized to construct beams, columns, and trusses, which are essential structural components. The high strength-to-weight ratio of steel enables the creation of lightweight yet robust structures capable of withstanding heavy loads and seismic forces. 3. Flooring: In industrial buildings, warehouses, and factories, steel sheets are often used as flooring material. Their smooth surface facilitates easy cleaning and maintenance, and their strength and fire-resistant properties ensure a safe working environment. 4. Wall partitions: Steel sheets are commonly used in the construction of wall partitions due to their stability and sound insulation properties. They can be easily cut and shaped to fit any design, allowing for flexible and customizable partition layouts. 5. Ductwork and HVAC systems: Steel sheets find extensive use in the fabrication of ductwork and HVAC systems. Their smooth and airtight surfaces enable efficient air movement and regulation, ensuring proper ventilation and temperature control in buildings. 6. Reinforcement: Steel sheets are frequently integrated into concrete structures as reinforcement. This enhances the strength and load-bearing capacity of the building, making it more resistant to bending, tension, and compression forces. 7. Safety and security: Steel sheets are utilized in the construction of safety and security features such as doors, gates, and window frames. Their high strength and resistance to impact and vandalism make them an ideal choice for ensuring the safety and protection of a building. In conclusion, steel sheets play a crucial role in construction for various applications, including roofing, cladding, structural components, flooring, wall partitions, ductwork, reinforcement, and safety features. Their superior strength, durability, and versatility make them an indispensable component in different construction projects, contributing to the overall safety, longevity, and functionality of buildings.

Send your message to us

Prepainted Galvanized corrugated Plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords