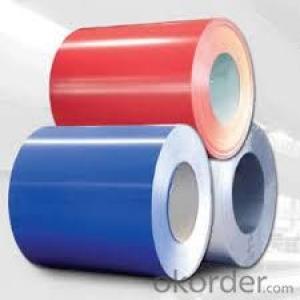

Prepainted Galvanized corrugated plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.material :

galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness :

normal use 0.3-0.6mm

3.length:

any length,according to the transportation,generally less than 12m

4.color:

standard color:red,blue,white,grey

special color:according to RAL color

Specification:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length,according to the transportation,generally less than 12m |

color | standard color:red,blue,white,grey |

special color:according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span:more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house,steel house,mobile house,modular house,villa,bungalow design,portable house/carbin,ready made house,kiosk booths,steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts,maufacturing shells of motors and so on | |

packing | plastic film,pallet or as your request |

Images:

- Q: Ok I know this sounds stupid but is there anyway to make stainless steel look older? It looks too new and I don't want it like that. Thanks.

- Just abuse it. You could hit with a hammer, expose it to flame, throw it at or grind it around on rocks or concrete, rub it with steel wool. (be artful in how you do this, the pattern could end up looking too deliberate if you're not careful.) For an example of naturally aged stainless steel, look at some cooking pots/pans. If you don't have any old ones, maybe your parents or someone you know does. They usually get a little banged up/scuffed/stained after a while. (I think the stainless just means it doesn't rust.)

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: What are the different types of steel coil slitting lines?

- There are several different types of steel coil slitting lines that are used in the metal processing industry. These lines are designed to cut large coils of steel into narrower strips, which can then be used for various applications. 1. Loop Slitting Lines: Loop slitting lines are the most common type of slitting line used in the industry. They consist of a decoiler, which holds the coil, a slitter head that cuts the coil into strips, and a recoiler, which winds the strips back into smaller coils. Loop slitting lines are versatile and can handle a wide range of coil widths and thicknesses. 2. Scrap Chopper Slitting Lines: Scrap chopper slitting lines are similar to loop slitting lines but include a scrap chopper unit. This unit cuts any excess material from the edges of the coil before it is slit into strips. This helps to improve the efficiency of the slitting process and reduces waste. 3. Double Loop Slitting Lines: Double loop slitting lines are used for high-speed slitting of thin-gauge coils. They feature two looping pits, which allow for continuous operation. While one coil is being processed, the other is being prepared for slitting, ensuring minimal downtime. 4. Turret Head Slitting Lines: Turret head slitting lines are designed for high-volume production and can process multiple coils simultaneously. They feature a turret head with multiple slitter knives, which can be quickly rotated to switch between different coil widths. This allows for faster and more efficient production. 5. Rotary Shear Slitting Lines: Rotary shear slitting lines are used for thicker and harder materials. They use a rotary shear instead of a slitter head to cut the coil into strips. The rotary shear offers better cutting performance and can handle higher tensile strength materials. 6. Combination Slitting Lines: Combination slitting lines are versatile machines that can handle a range of materials and can perform both slitting and cut-to-length operations. These lines are ideal for smaller manufacturers or those who require flexibility in their production process. Overall, the type of steel coil slitting line used will depend on the specific requirements of the manufacturer, including the type of material being processed, the desired strip width, and the volume of production.

- Q: I'm not really sure if carbon steel is considered a metallic material.

- Carbon and iron are both metallic.... so yes. You leave the iron laying in the forge - and it soaks up carbon atoms from the charcoal - so that as the steeling process goes on, the original iron becomes harder and harder.

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The railway equipment industry utilizes steel coils with dimensions that can vary according to the specific application and requirements. However, there are commonly observed dimensions for these steel coils, typically ranging from 3 to 5 feet in width and 10 to 15 feet in length. Likewise, the thickness of the steel coils exhibits variation, spanning from 0.01 to 0.5 inches. It should be noted that these dimensions are not set in stone and may fluctuate based on the specific demands of the railway equipment industry, such as the type of equipment being produced or the distinct purpose of the steel coils.

- Q: Can steel coils be coated with phosphorescent materials?

- Yes, steel coils can be coated with phosphorescent materials. Phosphorescent coatings can be applied to steel coils to create a glowing effect in low-light conditions.

- Q: So I was thinking about doing corset waist training and I wanted to know where I can get a real steel boned corset?

- Hi, okorder / There are 3 types of corsets: Fashion corsets, Authentic corsets and Waist training corsets. The fashion corsets are designed for light enclasping of body. They are made with plastics bones usually. The authentic corsets can reduce your waist size about 4 - 5 and the waist training corsets about 6. They both are made with steel spirals and flat bones. The waist training corsets are recommended for experienced wearers only. Look on info pages of the seller. The corsets reinforced with plastic bones are cheap with low durability.

- Q: What are the common coil weight and width combinations available for steel coils?

- The common coil weight and width combinations available for steel coils vary depending on the specific industry and application. However, some commonly available coil weight and width combinations for steel coils include weights ranging from 1 to 40 metric tons and widths ranging from 600 to 2,000 millimeters. These combinations can be tailored to meet the requirements of different manufacturing processes and end-user needs.

- Q: What are the common coil packaging methods?

- The common coil packaging methods include stretch wrapping, strapping, banding, and using coil covers.

- Q: Is infi steel as good as busse knives make it sound. If so why don't any other brands use it. Also are there any tactical folders that use infi steel. If infi isn't as good as it's cracked up to be then what is the best alternative.

- Infi Steel Knives

Send your message to us

Prepainted Galvanized corrugated plate / sheet-CGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords