Pre-Painted Galvanized Steel Sheet/Coil High Quality Prime

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

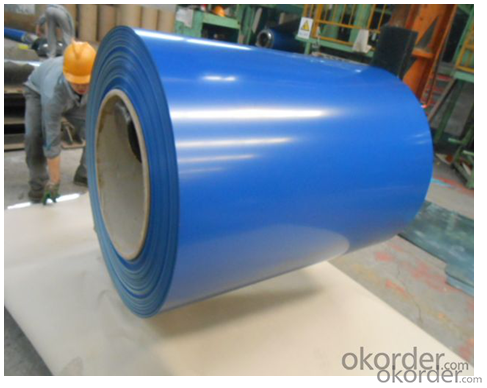

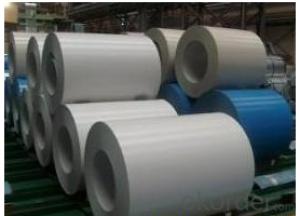

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling,

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I'm getting new strings on my dad's old acoustic guitar so I can learn how to play it and I'm wondering if I should get nylon or steel strings. Are there any major differences between the two aside from the nylon strings being easier on your fingers? Like do the Nylon strings sound different?

- If it's a classic guitar, then you should get nylon strings, because you can't use steel strings on a classic guitar, and you can't use nylon strings on an acoustic guitar , I would suggest that you buy a classic guitar, because it's really good for beginners.

- Q: why do you need to heat steel when hardening, molecules etc etc

- Gary is right, but maybe I can simplify it. It's very complex..... When you heat (hardenable) steel the carbon and iron form crystalline structures. Martensite and Austenite are most prominent, but there are others. Those are the hard crystals. When you quench it, those structures don't have time to dissolve as they would with slow cooling, so you freeze the crystalline structure in that state. Since that is too hard for most things, you temper it. Heating to a certain temp lets ~some~ of the crystals dissolve away. Annealing is heating and letting it cool slowly, so those structures will break up back into carbon and iron, leaving the steel soft. It's like a little atomic machine - crystals form, dissolve away, form again, with heat. It's waaaaay deeper than just that in detail, but that's the gist of it.

- Q: Want to get stainless steel sink. I want quality, durability, quiet, etc. Any suggestions??

- One part of our home is the kitchen, which is usually one of the busiest parts of the home. And part of it is the kitchen sink; as you look at the sink, you can hardly tell how much work is done in the sink. And in our daily activities, most of us use our sink in our own personal needs. Most of the time, we wash our face and clean our clothes, shoes and anything that needs to be washed in our sink. With this kind of job that the sink is going through in its everyday life, sink must be tough enough to take all the pressure of its job. Ordinary sink will not last long when it is use regularly. It may acquire rust, scratches and dent as we have use it in a regular basis, this is why we need to look for a sink that can manage to handle different usage and tasks in our home. In choosing a sink for our home, we must consider the quality and not the price alone. Stainless steel sink is easy to clean; stain and rust are needed not to worry because stainless steel sink is proven a rustproof material. But of course proper care for the sink should always be taken care of to make use of the sink for a very long time. In shopping for a sink, it can be hassle knowing that stainless steel sink is made of heavy material. And the good news is that stainless steel sink can be bought online. You can shop through the internet and you can have the freedom to choose a sink that will fit your kitchen.

- Q: Is Ace Steel's wrestling school still running?And do you know if their are any other wrestling schools in chicago?

- the Steel Domain wrestling school thats where cm punk got trained at i live in cleveland but i was in chicago last month and took a tour of the school.

- Q: i am working in a firm that deals with steels.. so it is necessary for me to understand the chemistry of the steels from their names so that i need not memorize all the grades with their metallury.. where can i find information about this nomenclature ? please help

- For steels with a four number code like 1020, 4140 ect the first two digits are the alloying information. I think you need to memorise those. 10 steels are plain carbon steel with no alloying. 41 steels are chrome-molly. The third and forth digits are the carbon content. 1020 is 0.2% Carbon, 4140 is 0.4% carbon. I don't know if there is a system to stainless steels.

- Q: I wanted to get a cheapo ring and I found one I like, but it's stainless steel. Is that bad? Will it get dull and tarnished fast?

- My hubby and I have some and they have stood up VERY well. He used to work with drywall, and the ring was SO easy to clean. I work with dogs and have not had a problem with my ring, either. They are heavy duty and stand up to time. LOVE them!

- Q: How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components in various ways. One common use is for the manufacture of steel beams and columns, which are essential structural elements in buildings and other large structures. The steel coils are processed and shaped into the desired dimensions, then cut and welded to form the beams and columns. Steel coils are also used in the production of roofing and wall cladding materials for construction. These coils are often coated with protective layers to enhance durability and resistance to corrosion. The coils are then shaped and formed into roofing sheets, wall panels, or siding materials that provide both aesthetic appeal and functional protection to the building. Another important application of steel coils in construction is for the production of reinforcing bars, commonly known as rebar. Rebar is used to provide strength and stability to concrete structures, such as foundations, slabs, and walls. The steel coils are processed and cut into specific lengths, then shaped and twisted to form the required reinforcement bars, which are then embedded within the concrete during construction. Furthermore, steel coils can be used in the production of various other construction components, such as pipes, tubes, and profiles. These components are used for plumbing, heating, ventilation, and other structural applications. The steel coils undergo different manufacturing processes, including rolling, welding, and shaping, to achieve the desired dimensions and properties of these components. In summary, steel coils play a crucial role in the production of construction components. They are used to manufacture steel beams, columns, roofing and wall cladding materials, reinforcing bars, pipes, tubes, and profiles. These components are vital for the construction industry, as they provide strength, durability, and functionality to buildings and other structures.

- Q: How are steel coils used in the production of containers?

- Steel coils are used in the production of containers as they are the primary material for manufacturing container bodies. These coils are shaped and welded into the desired container shape, providing strength and durability to the final product.

- Q: How are steel coils used in the production of metal ductwork?

- The production of metal ductwork relies heavily on steel coils. Typically constructed from high-quality steel, these coils serve as the primary raw material for manufacturing ductwork. To begin the process, the steel coil is unwound and then cut into specific lengths based on the required dimensions of the ductwork. These lengths are then shaped using specialized machinery, such as roll formers or bending machines, to achieve the desired form. The steel coils are essential in providing the necessary strength and durability to the ductwork, ensuring its ability to withstand the pressure and environmental conditions it may encounter during operation. Additionally, the composition of the coil allows for easy fabrication and customization, enabling manufacturers to produce ductwork in various shapes and sizes to meet specific project requirements. Moreover, steel possesses inherent properties that make it an ideal material for ductwork. Its resistance to corrosion and fire makes it highly desirable. Steel coils can also be coated with protective layers, such as galvanized or stainless steel finishes, to further enhance their longevity and performance. This added protection ensures that the ductwork remains intact and functional, even in harsh environments or when exposed to corrosive substances. In conclusion, steel coils are indispensable in the production of metal ductwork as they provide the necessary raw material for fabrication. Their strength, durability, and customization capabilities make them a crucial component in the manufacturing process, resulting in reliable and long-lasting ductwork systems.

- Q: How are steel tape measures installed?

- The spring piece is fixed on the shaft, the other end is connected with the measuring tape core, fixed tape shell with a shaft, the spring plate and a circle around the axis of the ruler core, wrapped after the ruler core extends from the outer end of the incision length of the shell, gently pull, the spring is tightened, the pull out the part from the incision and then removed around the shaft, then gently pull out, and then put the ruler core tied to the shaft, removed from the incision so repeatedly, until the spring to put all the ruler core recovery. Then a cotter pin on the central shaft installed on the lid, will tighten the screws.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil High Quality Prime

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords