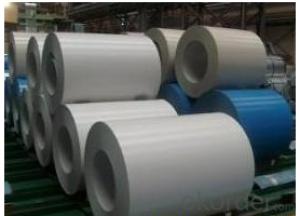

Pre-Painted Galvanized Steel Sheet/Coil Best Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Many gerber knives are made out of what gerber calls high Carbon steels and I was wondering if anyone knew exactly what is this mysterious steel.

- Carbon, when added to steel increases the hardness of the metal. The higher the carbon content the harder(pure carbon = diamond) the blade will be and the longer it will hold its sharpened edge. Too much carbon however can make it too brittle to use as a blade. iron, carbon and chromium(for the stainless in stainless steel) mixed in the right portion makes a high carbon stainless steel knife. All of which is kinda pointless if the blade is not forged correctly.

- Q: Why can hot rolled coils be placed outside?

- Because hot-rolled steel coils are generally used as raw material for semi-finished products, they have to be further used for pickling and cold rolling to make more use. The rust and dust can be removed after pickling

- Q: I had heard of steel braided fuel lines but ive also seen some air and coolant lines that are steel braided. Are these commonly used? I guess what I'm asking is if its a good idea to use them.

- Steel braided lines are mostly used in racing or off road applications or anywhere with rough service.

- Q: I heard about a new bike the specialized allez steel. Has anyone heard anything about it. it will have all brand new components like shimano 2300 parts and everything. it looks nice.

- Steel? I doubt it's made out of steel, more labor and a heavier frame. Most likely aluminum. Shimano 2300 you say? The Shimano 2300 is the lowest of the low of Shimano road components. Most likely not too reliable and heavy. www.cyclestore .uk/productDetai... I think this is what you might be looking for.

- Q: Does anyone know how to make a steel helmet, or does anyone know where to direct me websites-wise? i've just started looking on the web for info, so when i get back here i might've already found some info, but more wouldn't hurt, especially if from people who are interested on the subject. i know nothing about metallurgy, nothing on the art of metal working etc... please help.

- Steel okorder

- Q: this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- it sometimes rusts

- Q: How are steel coils used in the manufacturing of metal furniture?

- Steel coils play a vital role in the production of metal furniture as they are an essential component. Typically made from high-quality steel, these coils add strength, durability, and stability to the furniture. To incorporate steel coils into the manufacturing process, the first step involves cutting them to the desired length and width. This precise task is accomplished using specialized machinery and tools to ensure accurate dimensions for the furniture components. Once the coils are cut, they undergo shaping and forming processes to create various furniture parts such as chair frames, table bases, or cabinet structures. These coils can be bent, welded, or manipulated to achieve the desired shapes and designs. After the shaping process, additional treatments are applied to the steel coils to enhance their aesthetic appeal and provide protection against corrosion. This includes sanding, polishing, and the application of protective coatings or finishes to create a smooth and visually appealing surface for the furniture. In addition to their structural support and visual appeal, steel coils greatly contribute to the overall functionality of metal furniture. They possess excellent load-bearing capacity, ensuring that the furniture can withstand weight and pressure without bending or breaking. Furthermore, steel coils make metal furniture highly resistant to wear and tear, making it suitable for both indoor and outdoor use. With the ability to endure harsh weather conditions, these coils are particularly ideal for patio furniture or outdoor seating arrangements. In conclusion, steel coils are indispensable in the manufacturing of metal furniture as they provide essential strength, durability, and aesthetic appeal. Their versatility and reliability have made them the preferred choice for furniture manufacturers worldwide.

- Q: In terms of weight to strength titanium is stronger. But is it stronger than mild steel? If it is stronger, how much stronger is it?

- I was researching titanium as it pertained to protective footwear. The only thing mentioned was lighter as the advantage. Nowhere did I find the strength comparison. You might want to research the product you are interested in.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- Reinforced Steel is found in concrete, and if the towers were built with reinforced concrete (concrete beams with rebar) then they would likely still be standing. The twin towers were made of steel. When steel is heated up, it deforms and collapses, which is why it didnt stand up. One of the top 2 things against steel is that it is not fire resistant.

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- Those are all excellent quality knives so if the style of knife that you want is available from several makers it comes down to personal preference. I would go with SOG myself but the others are real good too.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil Best Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords