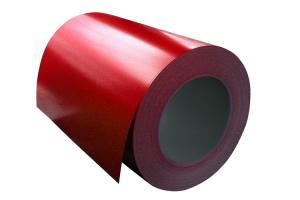

PRE-PAINTED GALVANIZED STEEL COIL WITH HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Painting steel is the product based on the metal sheet, of which surface is finally installed of the plastic film(PVC, PE) IN addition to being firstly covered with the coating and printed ink in. The coated layer of painting steel plate consists of chemical and filming layer, primer coated layer, pattern printed layer and surface coated layer. The top and back coating shall generally be the weatherproof paint, as well can be the application of the paint with special capabilities such as stain-resistant, self cleaning capability, high thermal resistance, antistatic capability, sterilizing capability, finger-print prevention and etc.

With GI(aluzinc) as base metal, after pretreatement(degrease and chemical treatment)and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc)steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Available specification:

PAINTING STEEL | |

BASE MATERIAL | HDGI, ALUZINC,CR |

GRADE | SGCC, DX51D,ASTMA653,EN10142,S350GD |

THICKNESS | 0.17-1.0mm |

WIDTH | 600-1250mm |

ZINC COATING | 60-200g/㎡ |

PAINT | PE,PVDF,SMP,HDP |

COILED | 508mm |

COIL WEIGHT | 3-6mt |

We can supply customers' with different specifications of the highest quality and lowest price.

Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied ,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit.

We are waiting for your feedback.

- Q: What are the different types of coil edge trimming machines?

- There are several types of coil edge trimming machines available in the market. Some common types include manual coil edge trimmers, pneumatic coil edge trimmers, and automatic coil edge trimmers. Manual coil edge trimmers require manual operation and are suitable for low volume production. Pneumatic coil edge trimmers use compressed air to power the trimming process, making them faster and more efficient. Automatic coil edge trimmers are fully automated machines that can handle high volume production, enhancing productivity and reducing labor requirements.

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- I have a combo of black and stainless in my kitchen; not sure which one is worse some days. For normal everyday stuff, hot, soapy (Dawn), clean dishwater and a microfiber cloth work great. For quick touch ups, a 50/50 mixture of window cleaner and rubbing alcohol also works great. The window cleaner gets the grease and the alcohol helps with streaks and makes the cleaner germ killing. Use with a microfiber cloth. For really nasty burned on stuff, I'd use a sponge with a non-stick cookware safe nylon scrub pad on it and some of the hot, soapy water. Just lay the damp sponge on the spot, let it soak a bit and see if it comes off. If not, try a little Barkeeper's Friend. Dampen, sprinkle, smear it around a little and let it soak for about 10 minutes. Then scrub with the sponge. Wipe up the residue with the microfiber cloth. The microfiber cloths are really key; they wipe more efficiently than any sponge, wipe, paper towel, dish rag. Get several and change them out frequently. You just wash and dry them; no fabric softener and you're ready to use them again. And it wouldn't hurt to keep a protective coat of a good stainless steel product on there either. That helps keep the stuff from getting such a good hold. But I've found that most of those are pretty bad at cleaning; so clean it first, then polish.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a mechanical device called a decoiler. The decoiler feeds the steel coil through a set of rollers, which gradually unwinds and straightens the coil, allowing it to be used for various applications.

- Q: What is the typical weight of a steel coil?

- The typical weight of a steel coil can vary depending on several factors such as the type of steel, the thickness, and the dimensions of the coil. However, on average, steel coils can range from a few hundred kilograms to several tonnes.

- Q: What are the common size limitations for steel coils?

- The size limitations for steel coils can vary depending on the specific requirements of the industry or application. However, there are commonly followed general size limitations in the steel manufacturing and distribution industry. Steel coils can have a width ranging from as narrow as 0.25 inches (6.35 mm) to as wide as 72 inches (1828.8 mm). This wide range allows for versatility in various applications, including automotive parts and construction materials. The thickness of steel coils can vary significantly, usually ranging from 0.006 inches (0.15 mm) to 0.5 inches (12.7 mm). Thinner coils are often used when lighter weight and flexibility are required, while thicker coils are commonly used in heavy-duty applications that require strength and durability. Consideration should also be given to the weight of steel coils, especially for transportation and handling purposes. Steel coils can typically weigh anywhere from a few hundred pounds to several tons. The weight limitations depend on factors such as the size of the coil, the steel grade, and the transportation and storage equipment used. Additionally, there are limitations on the outer and inner diameter of steel coils. The outer diameter usually ranges from 24 inches (609.6 mm) to 72 inches (1828.8 mm), while the inner diameter can vary from 16 inches (406.4 mm) to 24 inches (609.6 mm). These dimensions are crucial for ensuring compatibility with processing equipment and storage racks. It is important to note that these size limitations are not fixed and can be customized based on specific requirements. Steel manufacturers and distributors often collaborate closely with their customers to determine the optimal size and dimensions of the coils, ensuring efficient handling and processing.

- Q: Can steel coils be coated with vibration-damping materials?

- Yes, steel coils can be coated with vibration-damping materials.

- Q: I know that mild steel is more brittle than cast iron....but that is all.......please help??Thank you in advance......Ruby:D

- Actually, the opposite is true. CAST IRON is generally brittle, while mild steel is not. Cast iron has a carbon content from about 2%-4%. Mild steel has less than one tenth as much carbon as cast iron- around 0.2% - 0.3%. Cast iron also typically has from 1%-3% silicon. Most mild steel contains no more than 0.3% silicon. Steel melts at ~1450 degrees C. The addition of large amounts of carbon and silicon to C.I. lower the melting point to around 1200 C and make it more fluid than molten steel. Obviously this makes it easier to melt and to pour. The main advantage of cast iron is it's cheap to produce. It also has some desirable properties despite it's brittleness. For example it's easy to cut and carve with machine tools. It's also very heat resistant and excellent at absorbing vibration. For this reason C.I. was commonly used for engine blocks and exhaust manifolds in cars and trucks in the past, (Cast aluminum engine blocks are more common these days because Al is much lighter and conducts heat better.) Cast iron also rusts much more slowly than steel which is why it's still commonly used for pipes. C.I. pipes have been known to last 300 years.

- Q: and what are the four main elements in STAINLESS steel? x

- decreasing the carbon content fabric will strengthen the ductility, which will make it greater versatile. Carbon in metallic varieties brittle cementite (iron carbide) which will strengthen the hardness and capability of metallic.

- Q: Can steel coils be stored in unheated warehouses?

- Yes, steel coils can be stored in unheated warehouses as long as proper precautions are taken to prevent moisture and corrosion.

- Q: Is there a difference between hot rolled and cold rolled steel coils?

- Yes, there is a difference between hot rolled and cold rolled steel coils. Hot rolled steel coils are produced at high temperatures and have a rough, scaled surface with slightly rounded edges. They are generally used for applications that require less precise dimensions and a rougher surface finish. On the other hand, cold rolled steel coils are produced at room temperature and have a smoother surface with tighter tolerances and sharper edges. They are commonly used for applications that require precise dimensions, a smoother finish, and higher strength.

Send your message to us

PRE-PAINTED GALVANIZED STEEL COIL WITH HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords