Pre-Painted Galvanized Steel Sheet/Coil with High Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

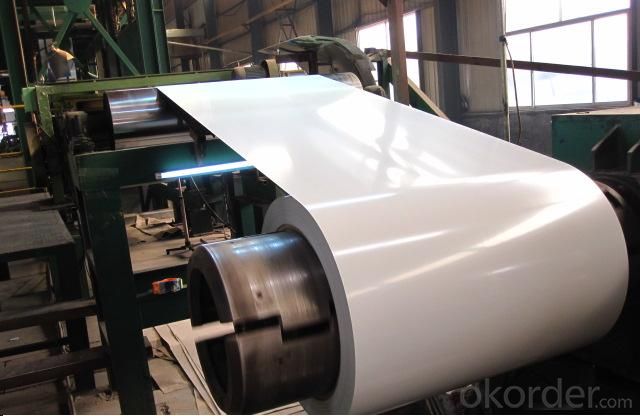

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.=

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the common coil loading and unloading procedures?

- The common coil loading and unloading procedures typically involve the use of specialized equipment such as cranes or forklifts to safely lift and transport the coils. The procedure may vary depending on factors such as the size and weight of the coils, as well as the specific requirements of the industry. Generally, the coils are loaded or unloaded by carefully positioning them onto or off of a designated storage area or transportation vehicle. The process often includes securing the coils with straps or clamps to prevent any movement or damage during transportation. Proper handling and adherence to safety protocols are crucial to ensure the successful loading and unloading of coils.

- Q: Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- no it is not, he made that up steel is a conductor and can't build static electricity. Compass needle is a magnet and as such was attracted to steel .

- Q: How can I judge the quality of steel?

- Various ways: Carry out mechanical testing on it to see how strong it is. eg. Tensile testing, hardness testing, impact testing. Examine a cleaned up sample on the steel under a microscope to see what the steel grain structure is like and what condition it is in (hardened etc.) Or the easiest way is to ask the supplier what it is and then find a specification sheet giving you all the above information.

- Q: What is stainless steel coil used for?

- Stainless steel coil is commonly used in various industries for manufacturing a wide range of products such as appliances, automotive parts, cookware, construction materials, and even surgical instruments. Its corrosion-resistant properties and durability make it an ideal material for these applications.

- Q: Steel roofing info. Pros and cons on steel roofing?

- Steel roofing Pro...life of product is much longer then Asphalt shingles....Looks great...multi colors.......Just love the stuff... Cons....More costly then singles at first but since it last longer it is really a better buy.......

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, which require specialized equipment and techniques for safe transportation and storage. Coils also tend to have sharp edges, posing a risk of injury. Additionally, maintaining the integrity and quality of the steel during processing can be challenging due to the potential for surface damage, rust, or deformation. Proper handling, storage, and processing techniques are crucial for minimizing these challenges and ensuring the efficient production of steel products.

- Q: i need working shoes for women that have steel toe shoes? What store do they sell them in . i live in c.a.

- You should find a Work World in your area. And sometimes Boot Barn will also have steel toed boots for women. I am a pipe fitter I work in refineries for long hours and I would reccomend Timberland womens steel toes with a composite toe. They are lighter than steel. Your toes wont get as cold and they are more comfortable. I would also reccomend putting an insert like Dr. Sholls to cushion your heels and toes. If your feet are small you will want to check around because our sizes arent as available as mens. Justin's are made entirely in the USA of very soft leather and they last long but you will need 6-8 weeks to wait for a special order and you can only get those at a boot barn location. good luck!

- Q: How are steel coils used in the production of steel locks?

- Steel coils are used in the production of steel locks as they are rolled into sheets and then cut into appropriate sizes to form the body and components of the locks. The coils provide a consistent and high-quality raw material that can be easily shaped and transformed into the desired lock designs, ensuring durability and strength in the final product.

- Q: I want to make a chess set out of stainless steel, but I'm not sure what type of mold I need or where I can go to have the steel melted and molded for me. Any ideas? I live in Southern, NJ.

- stainless steel is really hard to work with and will be really expensive to pour as not too many foundries do that. As far as tools go, I know that for e.g.drilling stainless steel cobalt bits are best, but even they don't last for very long. If you use normal drill bits stainless steel will ruin them. So how much metal working skills do you have? I would suggest to use a material you have experience with. Or make a chess set from nuts and bolts. You can buy them from stainless steel and the assembly is easy. See links for a few examples and/or use google to find more.

- Q: can you play one?

- i play acoustic, but i have tried to play a steel guitar before, my cousin has one. (:

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil with High Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords