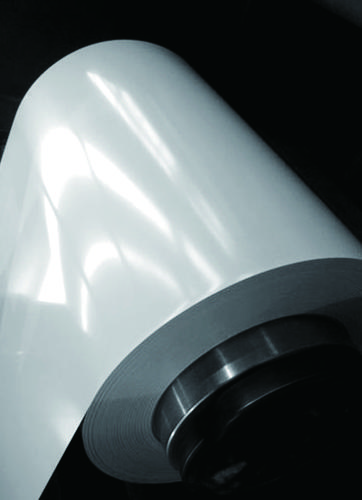

Pre-painted Galvanized Steel Coil-JIS G 3312-RAL9017

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Width:600mm-1250mm

- Q: Just wondering how good are forge steel screw drivers, tool boxes(organisers) and pliers are, as screw fix are having a january sale, and looking to add to my tool collection. Thanks in advance

- forged steel is a trick to get people like you who know nothing of steel to think of a blacksmith hammering away at a anvil making great tools. Not to say they are bad they are probably fine. but forged just means it was made when the steel was hot, it says nothing of the quality of steel in the process. however whenever steel is forged it will be stronger than the same product made out the same steel, but shaped by machining process.

- Q: How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties using various non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help to assess the strength, hardness, and other mechanical properties of the steel coils without causing any damage to the material.

- Q: What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: I'm building a single-speed commuter bike and I was wondering what the advantages and disadvantages of steel and alloy wheels are. Any experts out there who can give me specifics for each kind?

- Steel wheels are at the lowest cost and quality end of bike equipment. If you're even thinking of buying a cheapo bike with steel wheels - don't. Steel wheels are poor quality and therefore weaker than an OK alum rim. They are heavier, braking isn't as good, won't stay true as long. Alum wheels are extruded, not cast, and are better in every way. They cost more is the only down side.

- Q: How are steel coils used in the food processing industry?

- Steel coils are commonly used in the food processing industry for various purposes. One primary application is in the production of food packaging materials, such as cans and containers. These coils are transformed into thin sheets or strips that are then formed into the desired shape and size for packaging different food products. Steel coils are also utilized in the manufacturing of equipment and machinery used in food processing plants. This includes machines like conveyors, mixers, and slicers, which are crucial for the efficient and automated processing of food products. The durability and strength of steel make it an ideal material for these types of equipment, as it can withstand heavy usage and maintain its structural integrity. In addition, steel coils are used in the construction of storage and refrigeration facilities within the food processing industry. These coils are transformed into durable and insulated panels that are used to create walls and ceilings of cold rooms, freezers, and warehouses. The excellent thermal properties of steel help maintain the desired temperature and prevent spoilage of perishable food items. Furthermore, steel coils are employed in the production of cooking and baking equipment, such as ovens and grills. These coils are transformed into heating elements that provide consistent and efficient heat distribution during the food preparation process. This ensures that food is cooked or baked evenly, resulting in high-quality and delicious products. Overall, steel coils play a vital role in the food processing industry by providing the necessary materials for packaging, equipment, and infrastructure. Their strength, durability, and thermal properties make them a preferred choice for various applications within this industry, ensuring the production of safe and high-quality food products.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: What are the dimensions of steel coils used in bridge construction?

- The dimensions of steel coils utilized in the creation of bridges can fluctuate depending on the precise requirements of the bridge undertaking. However, in general terms, the dimensions of steel coils used in bridge construction typically fall within the range of 0.5 to 1 inch in thickness and 36 to 72 inches in width. The length of the coils may also differ, but is commonly around 20 to 40 feet. These dimensions enable the production of various fundamental structural elements, such as beams, columns, and plates, which are indispensable for bridge construction. It is noteworthy that the dimensions may vary based on the specific design and engineering specifications of the bridge project, as well as the type and load capacity of the bridge being constructed.

- Q: I'm in the middle of a remodel and buying appliances. Is there any way to ensure that the stainless steel is the same tone if you get different brands?

- it doesn't really matter. I have all appliances in my kitchen stainless steel. All different makes never noticed the tone, I think it just depends on the grain. i clean my appliances side to side not up and down. Good question never thought about that.

- Q: How do steel coil manufacturers minimize waste and maximize efficiency?

- Steel coil manufacturers can minimize waste and maximize efficiency through a combination of advanced technology, process optimization, and waste management practices. One way to achieve this is by using advanced automation and control systems in the production process. These systems can monitor and adjust various parameters such as temperature, pressure, and speed, ensuring that the manufacturing process operates at the optimal level. By closely monitoring and controlling these parameters, manufacturers can reduce the occurrence of defects and errors, which in turn minimizes waste. Another approach is to implement lean manufacturing principles. This involves eliminating any non-value-adding activities and streamlining the production process to reduce waste and increase efficiency. By carefully analyzing the entire production workflow, manufacturers can identify areas that can be improved, such as reducing setup times, eliminating bottlenecks, and optimizing material flow. This results in a more efficient and streamlined production process, minimizing waste and maximizing productivity. Furthermore, steel coil manufacturers can implement effective waste management practices. This includes proper handling and disposal of waste materials, as well as implementing recycling programs. By separating and recycling materials such as scrap metal, manufacturers can reduce the amount of waste generated and minimize the environmental impact of their operations. Additionally, manufacturers can explore partnerships with recycling companies to ensure that waste materials are properly managed and recycled. In summary, steel coil manufacturers can minimize waste and maximize efficiency by utilizing advanced technology, implementing lean manufacturing principles, and implementing effective waste management practices. By continuously striving for improvement and optimization in their processes, manufacturers can reduce waste, increase productivity, and ultimately achieve higher levels of efficiency.

Send your message to us

Pre-painted Galvanized Steel Coil-JIS G 3312-RAL9017

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords