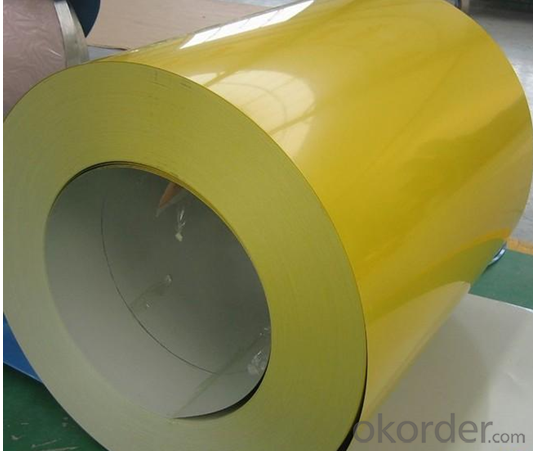

Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel coil processing equipment?

- There are several different types of steel coil processing equipment, including coil slitting machines, coil cut-to-length machines, coil leveling machines, and coil edge trimming machines. Each of these machines serves a specific purpose in the steel coil processing industry, helping to efficiently and accurately cut, shape, and prepare steel coils for various applications.

- Q: What are the different types of steel coil edge finishes?

- There are primarily three types of steel coil edge finishes: mill edge, sheared edge, and slit edge. The mill edge is the untreated edge of the steel coil, which is produced during the manufacturing process. The sheared edge is a straight cut made by a shear machine, resulting in a smooth and clean edge. The slit edge is created by cutting the coil along its width, typically using a slitting machine, and it may have a slightly rougher edge compared to the other two finishes.

- Q: Can steel coils be coated with scratch-resistant materials?

- Yes, steel coils can be coated with scratch-resistant materials. These materials are designed to provide an additional layer of protection to the steel surface, minimizing the risk of scratches or damage during handling, transportation, or storage.

- Q: Maybe it is obvious. But i have thought alot about it.I thought steel at a cool temperature was unbreakable. I am not one for science or physics or engineering (i am a political science major). But i don't understand why the planes that struck the world trade center on 9-11 didn't just dent the side and fall,How did the place break the steel? Was it the velocity? Is steel easily broken?I realized that i wasn't taught how the planes broke the steel, and that no one ever asked. I searched the web and i couldn't find the answer or even anyone who had asked the question before.(i don't care about conspiracy theories, i just want scientific facts)

- The buildings only had steel cores within the infrastructure to support the weight and flexibility - quite normal. You would be right if the whole surface of the building was pure reinforced steel with no openings (i.e. a ridiculous giant 100% purely steel tower). Can you imagine the force of a large jet at very high speed hitting a building, along with carrying vast amounts of highly explosive fuel. You don't need to, you've seen it... The bits of steel may well have been undamaged and collectable at ground zero, while the building was destroyed.

- Q: How are steel coils inspected for surface finish after processing?

- Steel coils are inspected for surface finish after processing through various methods such as visual inspection, surface roughness measurement, and non-destructive testing techniques like magnetic particle inspection or eddy current testing. These inspections help ensure that the steel coils meet the required surface finish standards and are free from any defects or imperfections.

- Q: We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- There's no such thing as a Steel mine - steel is made from various raw materials (and now recycled metals). These materials may be mined separately and then combined at a steel mill - but steel is made, not mined. Steel, depending on what final characteristics they're trying to develop (strength, hardness, finish , etc.) can be comprised of iron, carbon, manganese, phosphorus, sulfur, nickel, chromium, etc. in varying quantities.

- Q: How are steel coils used in the production of consumer goods?

- Steel coils are used in the production of consumer goods as raw materials for various manufacturing processes. They are often shaped, cut, or formed into different components and parts that go into products such as appliances, automobiles, furniture, and construction materials. Steel coils provide strength, durability, and versatility, making them essential in creating high-quality consumer goods.

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they serve as a primary material for constructing various components such as turbines, generators, and transformers. The steel coils are shaped, cut, and welded to create sturdy structures that can withstand high temperatures and pressures, ensuring reliable and efficient power generation.

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- Any okorder /

- Q: What is the role of steel coils in the electrical industry?

- The role of steel coils in the electrical industry is significant as they serve multiple purposes in various applications. Steel coils are used as components in transformers, which are essential for power distribution and voltage regulation. These coils are responsible for transferring electrical energy from one circuit to another, allowing for efficient transmission of electricity across long distances. Additionally, steel coils are utilized in the production of electric motors and generators. They are wound around the stator and rotor to create magnetic fields, which enable the conversion of electrical energy into mechanical energy and vice versa. This process is crucial in various industries, including automotive, manufacturing, and renewable energy sectors. Steel coils also play a role in the production of electrical cables and wiring. They are used to provide strength, durability, and protection to the conductive copper or aluminum wires within the cables. These coils are responsible for maintaining the structural integrity of the cables, ensuring safe and efficient transmission of electricity. Furthermore, steel coils find application in electrical equipment such as solenoids and relays, where they help create magnetic fields to control the flow of electrical current. They are also used in various electrical appliances, including refrigerators, air conditioners, and televisions, where they act as essential components in the functioning of these devices. In summary, steel coils have a vital role in the electrical industry. They are used in transformers, motors, generators, cables, and various electrical equipment, contributing to the efficient distribution, conversion, and transmission of electrical energy.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords