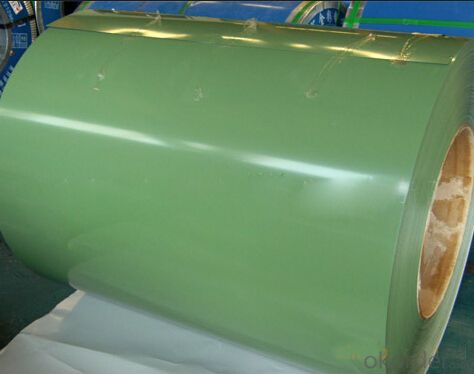

Pre-painted Galvalume /Aluzinc Steel Coils/PPGL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Introduction of Prepainted Galvanized Steel Coil:

Now, PPGI/PPGL has been widely applied to many kind of buildings. More and more contractor earn their reputation by using our products. You can see PPGI/ PPGL is extensively applied to shopping mall, industrial/agricultural building, hotel, restaurant, resort, office building or gymnastic facility. Our products help contactors to get their job done quickly and conveniently.

2.Usages of Prepainted Galvanized Steel Coil:

With excellent cold bending molded manufacturability, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

3.Prepainted Galvanized Steel Images:

4.Galvanized Steel Specification:

| Raw material | SGCC, SPCC, DX51D, G300,G550,A653 |

| Certificate | ISO9001.ISO14001.OHSAS18001 |

| Thickness | 0.15mm-1.5mm |

| Width | 1500mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | aluzinc coating |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤3T |

| Anti-MEK Wiping | ≥100times |

| Alu-Zinc coating | AZ60-AZ150g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | JIS G3312-2005,EN10169-2006,ASTM A653, GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | ACCORDING TO CUSTOMER'S SAMPLES OR RAL COLOR NO. |

| Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

5.Our Factory:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils inspected for oil or rust residues?

- Steel coils are inspected for oil or rust residues through a series of visual and physical examinations. First, the coils are visually inspected by trained personnel who closely examine the surface of the steel for any signs of oil or rust residues. They look for discoloration, stains, or any other abnormalities that could indicate the presence of contaminants. In addition to the visual inspection, various techniques are used to detect oil or rust residues. One common method is the use of solvent cleaning. A solvent is applied to the surface of the steel coil, and if any oil or rust residues are present, they will dissolve and become visible. This allows the inspectors to identify and remove any contaminants. Another method used for inspection is ultrasonic testing. Ultrasonic waves are sent through the steel coil, and any variations in the waves' reflections can indicate the presence of oil or rust residues. This non-destructive testing method provides a deeper analysis of the condition of the steel, ensuring a more thorough inspection. Furthermore, specialized equipment such as magnetic particle inspection or eddy current testing may also be employed. Magnetic particle inspection involves applying magnetic particles to the steel surface, which will gather around any areas with oil or rust residues. Similarly, eddy current testing uses electromagnetic induction to detect surface irregularities caused by contaminants. Overall, a combination of visual inspection and various testing techniques is employed to thoroughly inspect steel coils for oil or rust residues. These rigorous inspections ensure that the coils meet the required quality standards and are free from any contaminants that could compromise their performance or durability.

- Q: How can I tell the wear resistance, strength, ect from the name of the steel?how could I tell the difference between 420 and 440 steel. what does the HC in 420 HC steel mean? what do the numbers and letters in s30v steel mean?

- If your question implies how to tell the differences just by looking at the actual knife then I'd say there is no real way to do that. Just about all high carbon steel's look alike. You should be able to tell the difference between a stainless steel, but which one is anybodies guess, and a carbon steel however.

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- I have a stainless steel cooker which is a nightmare. I've also tried everything but find the only thing that works for me is to wipe over with a damp cloth then immediately dry it with a dry cloth.

- Q: What are the different types of steel coil slitting lines?

- There are several different types of steel coil slitting lines that are used in the metal processing industry. These lines are designed to cut large coils of steel into narrower strips, which can then be used for various applications. 1. Loop Slitting Lines: Loop slitting lines are the most common type of slitting line used in the industry. They consist of a decoiler, which holds the coil, a slitter head that cuts the coil into strips, and a recoiler, which winds the strips back into smaller coils. Loop slitting lines are versatile and can handle a wide range of coil widths and thicknesses. 2. Scrap Chopper Slitting Lines: Scrap chopper slitting lines are similar to loop slitting lines but include a scrap chopper unit. This unit cuts any excess material from the edges of the coil before it is slit into strips. This helps to improve the efficiency of the slitting process and reduces waste. 3. Double Loop Slitting Lines: Double loop slitting lines are used for high-speed slitting of thin-gauge coils. They feature two looping pits, which allow for continuous operation. While one coil is being processed, the other is being prepared for slitting, ensuring minimal downtime. 4. Turret Head Slitting Lines: Turret head slitting lines are designed for high-volume production and can process multiple coils simultaneously. They feature a turret head with multiple slitter knives, which can be quickly rotated to switch between different coil widths. This allows for faster and more efficient production. 5. Rotary Shear Slitting Lines: Rotary shear slitting lines are used for thicker and harder materials. They use a rotary shear instead of a slitter head to cut the coil into strips. The rotary shear offers better cutting performance and can handle higher tensile strength materials. 6. Combination Slitting Lines: Combination slitting lines are versatile machines that can handle a range of materials and can perform both slitting and cut-to-length operations. These lines are ideal for smaller manufacturers or those who require flexibility in their production process. Overall, the type of steel coil slitting line used will depend on the specific requirements of the manufacturer, including the type of material being processed, the desired strip width, and the volume of production.

- Q: 1045 surgical steel.

- There are many ways to sharpen knives. I guess your question is whether to use the steel that comes with knives, or a stone. Steels are only to straighten the edge, which is stropping. They won't sharpen a truly dull knife. For that you need a real sharpening system, of which a whet stone is one. The edge of a knife will get wavy with use - that's what the steel is for, to true it back up.

- Q: How are steel coils used in the food processing industry?

- Steel coils are commonly used in the food processing industry for various purposes. One primary application is in the production of food packaging materials, such as cans and containers. These coils are transformed into thin sheets or strips that are then formed into the desired shape and size for packaging different food products. Steel coils are also utilized in the manufacturing of equipment and machinery used in food processing plants. This includes machines like conveyors, mixers, and slicers, which are crucial for the efficient and automated processing of food products. The durability and strength of steel make it an ideal material for these types of equipment, as it can withstand heavy usage and maintain its structural integrity. In addition, steel coils are used in the construction of storage and refrigeration facilities within the food processing industry. These coils are transformed into durable and insulated panels that are used to create walls and ceilings of cold rooms, freezers, and warehouses. The excellent thermal properties of steel help maintain the desired temperature and prevent spoilage of perishable food items. Furthermore, steel coils are employed in the production of cooking and baking equipment, such as ovens and grills. These coils are transformed into heating elements that provide consistent and efficient heat distribution during the food preparation process. This ensures that food is cooked or baked evenly, resulting in high-quality and delicious products. Overall, steel coils play a vital role in the food processing industry by providing the necessary materials for packaging, equipment, and infrastructure. Their strength, durability, and thermal properties make them a preferred choice for various applications within this industry, ensuring the production of safe and high-quality food products.

- Q: Got small (.177) bb gun for fun with my son...From the manual:'Steel shot will fire at a higher velocity then lead shot with with the same muzzle energy. As a result, more caution is required when using steel shot because of a greater hazard of ricochet. Lead, because of its lower velocity, usually has less penetrating power and is less likely to ricochet.'Are you agree with that? ;)

- steel is made of iron mainly (and carbon) its density is 7.86 g/cm? approximately. and lead has density=11.4 g/cm?. so, if have same volume and shape steel will have less mass and thus will have greater velocity for same muzzle energy. I agree the manual. for more information on ricochet

- Q: Are Steel Building Kits really helpful while erecting a steel building?

- I put up a 30'x40' Mueller Steel Building from a bolt together kit 6 yrs ago. Fully insulated, 2 10'x10' roll up doors, 1 walk thru door, 3 windows, 2' overhang all around, and gutters. The building price minus the slab was about $9500. The only special equipment was a neighbor's large Farmall with a hay spike on the FEL that we used to lift the trusses in place. Then it was mainly cordless drills to put in LOTS of self tapping screws, circular saw with metal cutting blade, tall ladders, etc. Had help putting up the trusses and putting up the roof panels. Everything else I did by myself. Took about 6 wks, but that was only working weekends and maybe 3 evenings a week since that land is 30 miles from my house. Would have gone a lot faster with at least one helper.

- Q: What are the advantages of using steel coils in various industries?

- There are several advantages of using steel coils in various industries. Firstly, steel coils are highly durable and have a high strength-to-weight ratio, making them suitable for heavy-duty applications. Secondly, steel coils offer excellent resistance to corrosion, which is crucial in industries exposed to harsh environments or chemicals. Additionally, steel coils can be easily formed and shaped, allowing for flexibility in design and customization. Lastly, steel coils are recyclable, making them an environmentally-friendly choice while reducing waste and promoting sustainability.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- CS is a noxious gas that I have tasted. If it is spec mild steel then do so.

Send your message to us

Pre-painted Galvalume /Aluzinc Steel Coils/PPGL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords