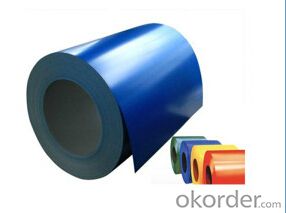

PPGI Prepainted Galvanized Steel Coils for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:DX51d SGCC DX52d

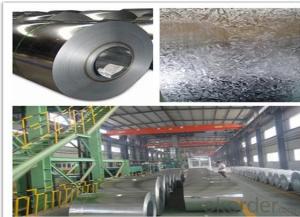

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Hot Dipped

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Dx51d

Thickness:0.3mm

Width:1250mm

Top Paint:15+5

Back Paint:5-7

ID:508mm

Coil Weight:3-8 Tons

Zinc Coating:50g-250g/Psm

Gloss:65%-80%

Feedback:Within 24 Hours

Export Markets:Global

Additional Info.

Packing:Export Standard Package

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:Shandong

HS Code:7210701000

Production Capacity:150, 000tons/Year

Product Description

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 30 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

Why Us:

1. ISO, BV, CE, SGS approved

2. Competitive price and quality from our own factory

3. Efficient service team online for 24 hours

4. Smooth production ability(50000tons/month)

5. Quick delivery and standard exporting package

6. Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc

| Name | 0.3mm Thickness PPGI Prepainted Galvanized Steel Coil |

| Resin constructure Technique of production | Double painting and double baking process |

| Productivity | 150,000Tons/year |

| Thickness | 0.12-1.3mm |

| Width | 600-1250mm |

| Coil Weight | 3-8 Tons |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000mm-1500mm |

| Zinc Coating | Z50-Z275G/psm |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Standard | JIS G3322 CGLCC ASTM A755 CS-B |

| SurfSurface coating coloace coating type | PE, SMP, HDP, PVDF |

| Back side coatingcolor | Light grey, white and so on |

| Application | PPGI is featured with light-weight, good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation |

- Q: So what's harder gold or steel

- steel. gold is pretty soft.

- Q: How are steel coils used in the manufacturing of transportation equipment?

- Steel coils are used in the manufacturing of transportation equipment as they provide a strong and durable material for various components such as frames, bodies, and chassis. These coils are often processed and shaped into different forms, allowing for customization and versatility in the design and construction of vehicles, including cars, trucks, trains, and ships.

- Q: What are the different types of welding methods used for steel coils?

- There are several types of welding methods used for steel coils, including: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, it uses a flux-coated electrode to create an arc between the electrode and the base metal, forming a weld. 2. Gas Metal Arc Welding (GMAW): Also called MIG welding, it uses a continuous wire electrode and a shielding gas, typically argon or a mixture, to create a weld. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, but instead of a solid wire electrode, it uses a tubular electrode filled with flux, which provides additional shielding and can be used with or without a shielding gas. 4. Submerged Arc Welding (SAW): It involves a continuous wire electrode and a granular flux that is fed under a layer of flux, creating a submerged arc and a highly efficient weld. 5. Resistance Welding: It utilizes electricity to generate heat and pressure, joining the steel coils together. Types of resistance welding include spot welding, seam welding, and projection welding. Each welding method has its own advantages and limitations, and the choice depends on factors such as the specific requirements of the steel coils, the thickness of the material, and the production process.

- Q: How do steel coils contribute to the automotive manufacturing sector?

- Steel coils are essential in the automotive manufacturing sector as they are used to produce various components such as body parts, frames, and suspension systems. The high strength and durability of steel coils make them ideal for ensuring the safety and structural integrity of vehicles. Additionally, steel coils are easily moldable, allowing manufacturers to create complex shapes and designs, contributing to the overall aesthetics and functionality of automobiles.

- Q: What are the common coil transportation options?

- The common coil transportation options include trucking, rail transportation, and shipping via barges or vessels.

- Q: i got a strip of steel from lowes how to sharpen it its not that thick its kinda slim but its heavyish its around 4'2 feet tall i cant get a whetstone or anything elsei have a brick , sand paper , and a hammer and some charcoal i was heating it up and trying to pound a edge into italso how to cut the steel to make a pointy curved tip any help appreciated and please tell me easy methodsplus its not sharp at all

- Bench grinder, Dremel Hand Grinder

- Q: What is the maximum diameter of a steel coil?

- The maximum diameter of a steel coil can vary depending on multiple factors such as the type of steel, coil weight, and the specific dimensions required by the manufacturer. However, in general, steel coils can range in maximum diameter from a few feet to several meters.

- Q: How are steel coils processed and shaped into different products?

- Steel coils are processed and shaped into different products through a series of manufacturing processes. The first step in the process is called uncoiling, which involves unwinding the steel coil and straightening it. This is usually done by feeding the coil through a machine called a decoiler. Once the coil is uncoiled, it goes through a process called leveling. This is done to eliminate any unevenness or warping in the steel. The coil is passed through a set of rollers that apply pressure and flatten the steel to the desired thickness. This ensures that the steel is uniform and ready for further processing. After leveling, the steel is typically cut into smaller pieces or sheets. This is done using machines such as shears or slitters, which can cut the steel into different widths or lengths. The precise dimensions will depend on the requirements of the specific product being manufactured. Once the steel is cut, it can undergo additional shaping processes. One common method is called roll forming, where the steel is passed through a series of rollers that gradually shape it into the desired profile. This is often used to produce products such as roofing sheets, wall panels, or beams. Another common shaping process is called stamping. In stamping, the steel is pressed between a die and a punch to create complex shapes or patterns. This is commonly used in the automotive industry to produce components such as car body panels or engine parts. In addition to shaping, the steel may also undergo surface treatments or coatings to enhance its properties or improve its appearance. This can include processes such as galvanizing, where a layer of zinc is applied to protect the steel from corrosion, or painting to provide a decorative finish. Overall, the process of shaping steel coils into different products involves a combination of cutting, shaping, and surface treatments. These processes are carefully executed to ensure that the steel meets the required specifications and is ready for use in various industries.

- Q: How can I owe a Pre-engineered Steel Building?

- You just have to do small efforts for owing a steel building: Firstly you have to finalize a steel building company for construction work. After finalizing the steel building company, the next step is the paperwork - the agreements and contracts. Some steel building companies may also ask for a verbal approval for the factories to get the work started.

- Q: what do you think about producebility of low density steel? for example: can density of 1020 steel (or ony others) be decreased without any loss of other properties.

- 1. A method has been developed for magnetic phase analysis of Fermanal type alloys as-quenched and after aging. 2. The upper limit of alloying to ensure the optimal mechanical properties was determined more precisely for steel 9G28Yu9MVB. For rods aged at 550°C for 16 h the aluminum content should not exceed 9.2% and the carbon content 0.92%. 3. To ensure the optimal mechanical properties of the deformed metal it is necessary to obtain a fine-grained single-phase austenitic structure after quenching. The amount of hardening phase after quenching should not exceed 15–20% (saturation magnetization around 1600 G).

Send your message to us

PPGI Prepainted Galvanized Steel Coils for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords