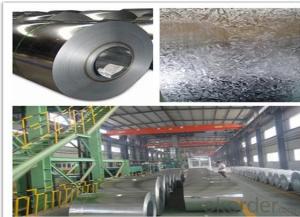

PPGI Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:DX51d SGCC DX52d

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Hot Dipped

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Dx51d

Thickness:0.3mm

Width:1250mm

Top Paint:15+5

Back Paint:5-7

ID:508mm

Coil Weight:3-8 Tons

Zinc Coating:50g-250g/Psm

Gloss:65%-80%

Feedback:Within 24 Hours

Export Markets:Global

Additional Info.

Packing:Export Standard Package

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:Shandong

HS Code:7210701000

Production Capacity:150, 000tons/Year

Product Description

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 30 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

Why Us:

1. ISO, BV, CE, SGS approved

2. Competitive price and quality from our own factory

3. Efficient service team online for 24 hours

4. Smooth production ability(50000tons/month)

5. Quick delivery and standard exporting package

6. Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc

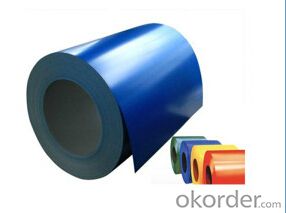

| Name | 0.3mm Thickness PPGI Prepainted Galvanized Steel Coil |

| Resin constructure Technique of production | Double painting and double baking process |

| Productivity | 150,000Tons/year |

| Thickness | 0.12-1.3mm |

| Width | 600-1250mm |

| Coil Weight | 3-8 Tons |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000mm-1500mm |

| Zinc Coating | Z50-Z275G/psm |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Standard | JIS G3322 CGLCC ASTM A755 CS-B |

| SurfSurface coating coloace coating type | PE, SMP, HDP, PVDF |

| Back side coatingcolor | Light grey, white and so on |

| Application | PPGI is featured with light-weight, good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation |

- Q: How are steel coils used in the manufacturing of engine components?

- Steel coils are used in the manufacturing of engine components as they provide a reliable and sturdy base material. These coils are often shaped, cut, and formed into various engine parts such as pistons, crankshafts, and connecting rods. The strength and durability of steel make it ideal for withstanding the extreme temperatures and stresses that engine components endure during operation.

- Q: How do steel coils contribute to durability and longevity in products?

- Steel coils contribute to durability and longevity in products due to their inherent strength and resistance to corrosion. By using steel coils as a material, products benefit from enhanced structural integrity and the ability to withstand heavy loads, mechanical stress, and harsh environmental conditions. The flexibility and resilience of steel coils also ensure that products can maintain their shape and functionality over a prolonged period, making them highly durable and long-lasting.

- Q: How do steel coils contribute to the marine industry?

- Steel coils contribute to the marine industry by being used in the construction of ships and offshore structures. They are essential for manufacturing various components, such as hulls, decks, beams, and structural supports. Steel coils provide strength, durability, and corrosion resistance, ensuring the longevity and safety of marine vessels and infrastructure. Additionally, steel coils are used for the production of marine equipment, including cranes, winches, and anchor chains, further enhancing the efficiency and functionality of the marine industry.

- Q: How do steel coils contribute to sustainability in construction?

- Several factors contribute to the sustainability of construction when it comes to steel coils. To begin with, steel is an incredibly durable material with a long lifespan. Its use in the construction of structural components like beams, columns, and frames ensures the stability and strength of buildings. This durability translates to reduced maintenance requirements and a longer service life for structures. As a result, the need for frequent repairs or replacements is diminished, leading to a decrease in the overall environmental impact associated with material waste and energy consumption. Moreover, steel is highly recyclable. Steel coils can be easily recycled and reused in new construction projects. The recycling process for steel has a significantly lower environmental impact compared to the production of new steel. By incorporating recycled steel coils into construction projects, the demand for new steel production is reduced, resulting in lower greenhouse gas emissions and a smaller carbon footprint. This approach helps conserve natural resources, reduces the extraction of raw materials, and minimizes energy consumption in steel production. Additionally, steel is an ideal material for off-site prefabrication. This means that steel coils can be manufactured in controlled environments in factories, minimizing construction waste and improving construction efficiency. Prefabricating steel coils reduces on-site material waste and decreases the need for transportation of construction materials. Consequently, this reduces air pollution and energy consumption during construction. Furthermore, steel's high strength-to-weight ratio allows for lighter and more efficient structures. By using steel coils, construction projects can optimize material usage, resulting in reduced material consumption and lessening the overall environmental impact. The lightweight nature of steel coils also facilitates easier transportation, reducing fuel consumption and associated emissions during delivery. In summary, steel coils contribute to the sustainability of construction through their durability, recyclability, prefabrication capabilities, and high strength-to-weight ratio. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce energy consumption, and decrease the environmental impact, ultimately promoting a more sustainable built environment.

- Q: What are the different thickness tolerances for steel coils?

- The different thickness tolerances for steel coils can vary depending on the specific requirements and industry standards. However, some common thickness tolerances for steel coils include: - Standard Tolerance: This tolerance typically ranges from ±0.005 inches to ±0.010 inches, meaning that the actual thickness of the steel coil can deviate within this range from the specified thickness. - Tighter Tolerance: In some cases, stricter tolerances may be required, especially for critical applications or industries. Tighter tolerances can range from ±0.002 inches to ±0.005 inches, ensuring a more precise thickness control for the steel coils. - Custom Tolerance: Depending on the specific needs of a project or customer, custom thickness tolerances can be defined. These tolerances can be either looser or tighter than the standard or tighter tolerances, depending on the application and the desired level of precision. It is important to note that different industries and applications may have their own specific tolerance requirements. For instance, industries like automotive or aerospace may require tighter tolerances due to the critical nature of their applications, while other industries may accept looser tolerances. Additionally, the specific type of steel being used can also impact the acceptable thickness tolerances. Therefore, it is crucial to consult the relevant industry standards and specifications to determine the appropriate thickness tolerances for steel coils in a particular application.

- Q: I am buying a knife for my future husband for his wedding gift and I was wondering what is better carbon steel or stainless steel?

- carbon steel is my choice. googlecarbon steel vs stainless steel knives for more info. If you buy stainless make sure it is an alloy that will hold an edge..many a shiny knife is just a dull dud. Carbon blades don't rust unless they are left laying in the wet. I was having this conversation with a Friend once. So I took his knife and struck his knifes edge against mine with a light blow.. His had a 1/16 dent in it, mine not even a mark on it. I assume this is not a kitchen knife.

- Q: Alright...Please tell me what I can and can't buy for Steel Legion in detail(Much Detail please)Ogryns.Las canons.The problem I'm having is that they don't have steel Legion Uniform..does it matter?1.I also heard that you can't use Commisar Yarrick.(So what could I use?)2.What are my Hq choices,Fast attack,Heavy Support,Elite etc.3.Steel Legion has a Commisar....(Do I buy one for each squad of Steel Legion or one?)Please in detail what should I buy...I don't have the codex yet but will soon!!4.I also heard that if I get Steel Legion I need a transport for everything?(Is this true?)5.Please be detail on what i can't and can buy!!(Please like HQ Squad leader,Sargent)

- here are a couple of things about the steel legion. you should have a lot of mechanized units, have chimaras for rvery squad if posible, artillery fire helps a hell of a lot. also sentinals and leman russes and hell hounds also help. if in apocolypse, use banblades and titans. storm trooper squads should be your base squadrons. put them in chimeras and get near the action, drop 'em off and rapid fire like CRAZY!!! the steel legion loves heavy weapons so remember to get some heavy weapons platforms. there favourite weapons are grenade and missle launchers. there is also an officer you can buy with a power sword with the steel legion look. steel legion are big xeno hunters. because commisar is a ork killer you should be allowed to field him. ratling/ sniper squads also help and if you can get a vindicare assassin that is very useful.

- Q: What type of metal is T10 tool steel?

- Carbon Tool Steel usually in the form of forged bar stock. Steel Grades for tool steel can be any of the following (depending on the application) T10/1.1645 SK3/SK4/W1A-91/2/ TC105/y10/1880/BW1B T10A/1.1545/y10A/1880 Standards are published by: DIN, JIS, ASTM, AISI, BS, SS, ISO, TOCT, GB Doug

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- carbon steel it is stronger it is the type ill be using when i stare forging

- Q: As we all know Shaq killed the movie Steel by suckin so bad but does anyone know what happened to the comic book version.

- Steel's own series was cancelled around issue #50, after which he went on to a co-starring role in Superman: The Man of Steel. Steel was eventually injured in a battle with Darkseid, at which time his niece Natasha took on the role of Steel. John Henry recently resurfaced in his heroic identity in 52, where he's been injected with Lex Luthor's metagene, making his body living stainless steel.

Send your message to us

PPGI Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords