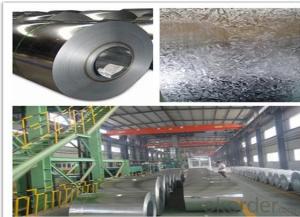

Hot Prepaint Galvanized Steel Coil and PPGI for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description.

Surface Treatment:Coated

Technique:Cold Rolled

Standard:ASTM, JIS, GB

Application:Roof Panel,Wall Panel in Steel Structure Warehouse

Steel Grade:Q235B

Width:1000,1219,1200,1250mm

Thickness:0.17-1.0mm

Export Markets:Global

Additional Info.

Packing:Sea Packing: Standard Seaworthy Packing or Accordi

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:Hebei, China

HS Code:72107010

Production Capacity:500, 000 Tons/Year

Product specification:

* Product Name: GALVANIZED STEEL COIL ,SGLCC

* Base Material: Galvanized Steel Coil.//SGLCC

* Width:700-,1250mm (The special width 914mm,1219mm,1220mm will be available )

* Thickness:0.3 -1.0mm Thickness tolerance: +/- 0.02mm

* Al-Zn coating: 30-150g /sq.m. or can be provided as clients' requirements

* Inner diameter of coil: 508mm&610mm.

* Packing: Standard seaworthy packing or according to user's need.

* Weight of each coil: 9 tons max

* Guarantee/ warranty

*Delivery time: Within 10-20 days.

USAGE

1.used as roof panel and wall panel in steel structure warehouse, factories, exhibition hall, container houses, cold storage,

2.it is also mainly used in light industry, automobile, construction, animal husbandry, fishery, and commerce,

PRODUCT PACKING

*Metal band strapping

*Outside diameter ring

*Label

*Protective steel sheet

*Water and rustproof paper

*Steel sheet

- Q: How are steel coils used in the production of steel wire?

- Steel coils are used in the production of steel wire by being uncoiled and then fed through a series of machines that stretch and draw the steel into the desired wire thickness.

- Q: explain what happen if carbon steel is exposed to an oxygen rich atmosphere at elevated temperature inside a furnace.

- Assuming the steel isn't actually melted, two things will happen. First, a layer of iron(ii) oxide, FeO will slowly develop on the surface, getting thicker over time. This layer is usually poorly bonded to the metal surface, it tends to flake off, exposing fresh metal. This is known as mill scale, it's also known as wustite which is the mineral term. Second, the surface of the steel will become decarburized, essentially becoming pure iron, not steel. The depth of the decarburized layer depends on the temperature, time, and the diffusivity of carbon in the steel at the given temp. This has some implications to engineering, in hot-rolling or forging of steel shapes for example. It's often the case that the stress and strain in a material is greatest at or near the surface. Therefore the weakened, decarburized layer at the surface may have a much greater detrimental effect on the steel's performance than might be expected. In a more specific example, die and tool steels depend on their carbon content for their strength and wear resistance, Therefore if such steels are heated in an oxidzing atmosphere, wear resistance is totally destroyed: The thin decarburized iron layer will be extremely soft and malleable.

- Q: How do steel coils contribute to the marine industry?

- The marine industry heavily relies on steel coils due to their multiple uses that contribute to the advancement, upkeep, and effectiveness of marine vessels. Initially, steel coils are crucial in ship and offshore platform construction. Their exceptional strength and durability make them ideal for the hull structure, ensuring the vessel's integrity and safety, even in harsh marine conditions. Furthermore, steel coils find application in the production of various marine equipment and parts. For example, they are utilized in the manufacturing of propellers, shafts, and rudders, which are vital for steering and propelling ships. By using steel coils in these components, their ability to withstand the corrosive impact of seawater is ensured, thereby prolonging their lifespan and reducing maintenance expenses. Moreover, steel coils play a significant role in the fabrication of marine pipelines and infrastructure for oil rigs. These coils are transformed into pipes and tubes that are essential for transporting oil, gas, and other fluids. The strength and corrosion resistance of steel coils are crucial in guaranteeing the dependability and safety of these pipelines, as they must endure extreme pressure and exposure to saltwater. Additionally, steel coils are also involved in the maintenance and repair processes of the marine industry. Whenever a ship undergoes renovations or repairs, damaged or corroded sections are often replaced with steel coils. The versatility of steel coils enables them to be molded and welded into various shapes and sizes, making them suitable for diverse repair applications. Overall, steel coils make a substantial contribution to the marine industry by providing the necessary strength, durability, and corrosion resistance required for the construction, maintenance, and efficiency of marine vessels. Their utilization in shipbuilding, component fabrication, pipeline construction, and repair procedures renders them indispensable for the growth and sustainability of the marine industry.

- Q: How are steel coils used in the production of steel framing systems?

- Steel coils are used in the production of steel framing systems as they are unrolled and fed into a machine that shapes and cuts the steel into the desired lengths and profiles. These coils provide a continuous supply of high-quality steel, allowing for efficient and precise manufacturing of steel framing components, which are then assembled to create sturdy and durable steel structures.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: Can steel coils be coated with light-reflective materials?

- Yes, steel coils can be coated with light-reflective materials.

- Q: Question about steel type used in bridges.?

- Do you mean galvanized steel?

- Q: What are the different methods of pickling steel coils?

- There are several methods of pickling steel coils, including the use of acid pickling baths, electrolytic pickling, and pickle lines. Acid pickling baths involve immersing the steel coils in a bath of acid solution, such as hydrochloric or sulfuric acid, to remove scale and impurities from the surface. Electrolytic pickling uses an electric current to remove the scale from the steel coils, while pickle lines involve passing the coils through a series of acid baths and rinses to clean and prepare the surface for further processing.

- Q: How are steel coils used in the manufacturing of pressure vessels?

- Steel coils are used in the manufacturing of pressure vessels as they provide a strong and durable material for construction. These coils are typically formed into cylindrical shapes, which are then welded together to create the vessel. The steel coils provide the necessary strength to withstand high pressure and ensure the safety and reliability of the pressure vessel.

- Q: how do i quinch steel? i heard instead of water oil will actually make it harder... wat ways are best for wat steels? and how do i tell wat kind of steel i have?... i will be doin this with my poket knife..

- boy what a though question ! let me explain. when you rapidly cool a steel from high temperatures(depending on steel type) with water or oil or other means , it is called quenching. it depends on the steel type to say if it is better to quench it with oil or water but basically in water you will have a harder steel rather than oil. for some steels if you do this you will ruin it's properties ! you can't totally tell what kind of steel do you have until you get it analyzed with Quantometer analyzer with a pocket knife it is more like an estimation and it can't be trust able generally if you can scratch the steel with your knife it means it is not a hard steel and it might not be expensive. I hope that helps but for more information i need to know more !

Send your message to us

Hot Prepaint Galvanized Steel Coil and PPGI for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords