Porcelain Tile CMAX ZG-JW8001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

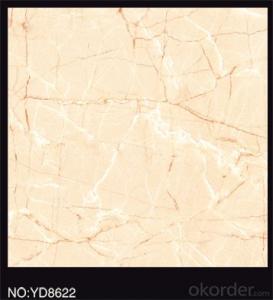

Specifications of Porcelain Tile CMAX ZG-JW8001

1.Polished porcelain tile

2.Great natural stone image and high glossy degree

3.Water absorption:<0.5%

4.Sizes: 600 x 600mm or 800 x 800mm

6.Product features: resistance to fading, staining and discoloration, easy to clean

7.Package: carton + strong wooden pallet

8.Transportation: by sea

9.Package: 4 pcs/Ctn for 600mm; 3 pcs/Ctn for 800mm

Applications of Porcelain Tile CMAX ZG-JW8001

1.Suitable for homes flooring tiles

2.high grade office buildings

3. high-grade hotel flooring tiles,

4.government and corporate projects flooring tiles

5.deluxe clubs flooring and wall tiles

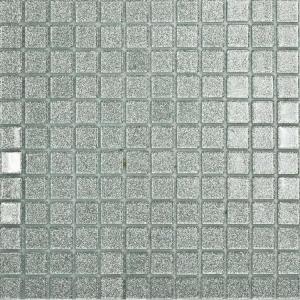

Pictures of porcelain tiles

Usage of porceain tile

Polishing Line of porcelain tile

Packing Line of porcelain tile

Certificate of porcelain tile

Advantages of porcelain tile

Green Product

Guarantee/Warranty

International Approvals

Packaging

Price

Product Features

Product Performance

Prompt Delivery

Quality Approvals

Reputation

Service

Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Here you can find good products, better price and the best service!

Looking forward to receiving your inquiry

- Q: I recently put in a wood stove. It was professionally installed and certified to meet fire regulations. I don‘t know anything really about the install just that it doesn‘t require any r value underneath it. It just requires a pad for embers. There was a long waiting list to get it installed but an opening came up and we got it installed sooner than we planned. So we didn‘t get the tiling done. Currently it is sitting on a base made with 2x6s spaced 6 apart covered with 3/4 plywood and a sheet of durock cement board attached with durock screws and all seems taped with durock tape and covered with durock cement plaster. I want to finish it with tile. However, the stove is too heavy for us to lift. Its a pedestal woodstove so would it look okay tile up to the pedestal? If so how much space should I leave against the pedestal? What should I put in the gap? High-heat caulking? I‘m very new to this so any advice is welcomed. Thanks!

- when you tile you will also be using grout between each tile this same grout is what will fill the void between the tile and your stove. as to how much space should be between you will want to pick up some spacers when you get your tile as well as the grout,tile adhesive,a spreader,a sponge and a simple tile cutter.ps most places that sell tile will also be able to give advice as to how to complete your project.

- Q: It‘s been a while since I have done tile, but I remember we used to use sheetrock to cover the floor or for back splash wall, however I don‘t remember what it was used for. Is there special cases when you need to use it or do I need to use it every time? What is the purpose to use the sheetrock?Please help. Thanks.

- You never use a sheetrock to do tile. Only as a normal wall covering to be painted in a non wet area such as a back splash or a wainscot. Then that you can tile over. You may have used a product ( or one similar) called Denshield. This is a 1/2 special backer board you can use on floors and you work with it just like a sheet rock. because it was a light weight fiberglass impregnated gypsum board. Just like the 1/2 cement board you could use it on floors and wall where moisture is present and you installed it in a thinset bed of mortar prior to nailing it down. Sheet rock is a general term for dry wall, used for regular walls to be painted. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: We have a hardwood floor in our bathroom, and because it gets too damp, we want to install vinyl tiles on top of the hardwood floor. But I cannot imagine vinyl sticking to wood - can it be done successfully? Any glue tips??

- If you do that you will STILL have a hardwood floor that will get damp, only it will be underneath vinyl tiles, and you might find problems in the future with buckling, swelling etc because the vinyl and wood will not shrink or expand at the same rate. Best just to take an extra day, remove the hardwood and start fresh

- Q: I have strip kitchen floor to sub floor. i am ready to install tiles. My question is: How to do the wet bed for laying ties later on.

- I m assuming yo mean a mortar bed or a mud bed for tiles. You don t want to do this for later on as you say. You want to lay tiles soon after it s set so you don t ruin the mortar bed by walking on it. This isnt something you usually just do , it takes practice and a bit of experience and is hard work but worth it when done right. A wet bed is a base of cement that the tiles are installed as you go. Old fashion method rarely used anymore. Now a mud bed is used and then a thin set is used to adhere the tile down. If you want to do a mud bed e mail me through my avatar and I ll guide you through it. GL

- Q: We‘re renovating an old house, and the ceramic tile on the bathroom walls is just awful. I‘d like to replace the wall tile with beadboard. The tiles appear to be mortared directly onto the drywall. Is it a good idea to install the beadboard directly over the ceramic tile? Or should we chip of the tile or remove the lower portion of the drywall? I‘d like to do this as easily as possible, but not at the risk of shoddy workmanship.Also - all the beadboards I‘ve looked at are either painted or primed on the front surface, with a bare wood surface on the rear (glued to the wall). Is it advisable to paint/prime the rear surface as well before installation? With all the steam and moisture in a bathroom, I can envision the panels buckling. Is there a particular paint/primer that seals off from moisture particularly well?

- It's better to remove the tile altogether, including the old backer board. We did that as insurance, we found there was no insulation in the wall so it was good that we did. Cover the entire wall with sheetrock (green board, meant for a wet location) then glue the beadboard in place with water proof adhesive (applied with a caulk gun). It's worth the extra time and effort for your own house and you'll know it's done correctly and will last for many years to come. Good luck, been there done that and still in the process. It's a labor of love, I guess! :o)

- Q: We have tiled around our jetted tub about halfway up the wall and the top and around the edges does not look finished. Do we add trim there or something else?

- There are lot's of choices, bullnose being the most common. Go to a tile store, not just Lowes or Home Depot, you'll get lot's of ideas.

- Q: Once I removed the old tiles is there anything else I should do before I lay the new ones?

- Make shore to remove all thinset from floor before installing new tile

- Q: I ripped up all the existing tile, it was small tiles that I had to chisel up. There is quite a bit of thinset that is bonded to the wood floor and its impossible to get it all up. If I try and chisel it all off I end up ripping up the wood and making it worse.I think the wood sub floor is sitting on another older piece of sub floor but i‘m not sure.What are my options here?- put cement board over it (do i need to put waterproof membrane?) and then tile it? If I do this the bathroom floor will be slightly higher then the hallway floor.- Can I use self leveler on the wood subfloor and then tile over it? it would probably be the ideal height.- Do I chance ripping up the subfloor and doing cement board and then tile?Am I missing any other options?

- I would try removing most of the thinset with a hand-held power scraper. You can rent these.

- Q: Including the ground and the wall, need to pay attention to what aspects of the problem? Decoration has no experience, hope to say the details, thank you

- On the stickers of the brick vertical and horizontal lines are straight, wrong paste the wrong degree of brick to be consistent; flatness is better, brick angle can not have high and low gap, can not have empty paste; cement mortar shall not overflow the length of 1 / Brick angle and edge line shall not leave stains, imprints, scars; reserved water and electricity mouth to the edge of the neat, fixed water pipe interface protruding brick surface height reasonable; residual corner more than reasonable.

- Q: Can anyone tell me what type of tile this is? Name?

- Sure is a ceramic tile. Could be a porcelain bodied tile with a glazed surface but they are all classified as ceramic. Ceramic with a slightly beveled edge for a bit different look. Getting the name is almost impossible unless it came from a magazine where you can get it or at least the brand name of the manufacturer. Any questions you can e mail me through my avatar and check my qualifications there. GL

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2010 |

| Annual Output Value | US$ 25 Million - US$ 50 Million |

| Main Markets | 50.00% Mid East 10.00% Eastern Europe 10.00% South America 8.00% Southeast Asia 5.00% Domestic Market 5.00% Africa 2.00% South Asia 2.00% Northern Europe 2.00% Eastern Asia 2.00% North America 1.00% Southern Europe 1.00% Central America 1.00% Western Europe 1.00% Oceania |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Porcelain Tile CMAX ZG-JW8001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches