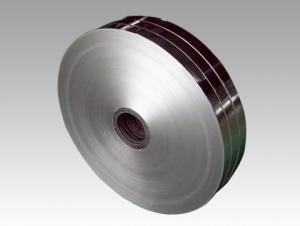

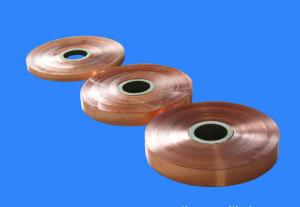

Polyester film PET Roll for cable insulation wrapping

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 yd²

- Supply Capability:

- 500000 yd²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of PET Filme

Width: 9mm-3500mm

Length: as clients need

Thickness:10-270Micron

Materials: 100% Polyester(PET)

Core size: 3”, 6”

Feature of PET Filme

High tensile strength

One side corona/double sided corona or non corona treatment are available

100% waterproof and instantly dry

Stable quality1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

Packaging & Shipping

Packaging Detail | standard packing / genuine packing / as per customer's packing instruction |

Delivery Detail | 15 ~ 30 days after receiving the deposit |

Our Service

1.We have good and professional team

2. We accept any drawings or your samples to develop new product

3. Any small problems will be solved at the most prompt time

4. We always offer relative technical support, quick response, all your inquire will replied within 24 hours

FAQ: What are your company advantages?

Company Advantages:

1.Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Are there any regulations or restrictions on using olive nets?

- Yes, there are regulations and restrictions on using olive nets. These can vary depending on the region and country. Some common regulations include obtaining permits or licenses for using nets, adhering to specific mesh size requirements, and following guidelines to prevent damage to the trees or environment. It is advisable to consult local agricultural authorities or olive farming associations to understand the specific regulations in your area.

- Q: How do olive nets prevent olives from getting sunburned?

- Olive nets prevent olives from getting sunburned by providing shade and reducing direct exposure to the intense sunlight, thus protecting the delicate fruit from heat stress and sun damage.

- Q: Can olive nets be used for olive tree disease management?

- No, olive nets are primarily used for harvesting olives and protecting them from birds, not for disease management in olive trees.

- Q: Are there any specific guidelines for using olive nets on olive trees with delicate branches?

- Yes, there are specific guidelines for using olive nets on olive trees with delicate branches. It is important to choose a net with small mesh size to prevent any damage to the delicate branches. Additionally, the net should be installed carefully to avoid any rubbing or snags on the branches. Regular inspection and maintenance of the net is also necessary to ensure it remains secure and does not cause harm to the olive tree.

- Q: Can olive nets be used on olive trees in different geographical locations?

- Yes, olive nets can be used on olive trees in different geographical locations. The use of olive nets is not restricted to specific regions, as they can be beneficial in protecting the olives from birds and other pests, regardless of the location.

- Q: Can olive nets be used in combination with fertilization practices?

- Yes, olive nets can be used in combination with fertilization practices. The nets can protect the olive trees from pests and birds while the fertilization practices ensure optimal growth and productivity.

- Q: Can olive nets be used in hilly or sloped areas?

- Yes, olive nets can be used in hilly or sloped areas. The nets are designed to be adjustable and can be secured to adapt to the terrain, allowing them to effectively cover olive trees and prevent olives from falling on uneven surfaces.

- Q: How do olive nets prevent bird droppings from contaminating olives?

- Olive nets prevent bird droppings from contaminating olives by creating a physical barrier between the birds and the fruit. The nets are spread over the olive trees, preventing birds from accessing the olives and reducing the likelihood of droppings falling onto the fruit.

- Q: How do olive nets help in reducing the risk of sunburn on olive fruits?

- Olive nets help in reducing the risk of sunburn on olive fruits by providing shade and protection from direct sunlight. The nets create a barrier between the fruits and the sun, preventing excessive heat and UV rays from damaging the delicate olive skin. This reduces the likelihood of sunburn, which can lead to fruit blemishes, decreased quality, and lower yield. Additionally, the nets also help regulate temperature and humidity levels around the fruits, creating a more favorable environment for their growth and development.

- Q: How effective are olive nets at preventing fruit damage?

- Olive nets are highly effective at preventing fruit damage. They act as a physical barrier, keeping birds and other pests away from the fruit, thus reducing the risk of damage caused by pecking and feeding. Additionally, olive nets also provide protection against wind and hail, further ensuring the fruit remains intact.

Send your message to us

Polyester film PET Roll for cable insulation wrapping

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 yd²

- Supply Capability:

- 500000 yd²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords