Black Anodized Aluminum Sheets - Polyester Coated Aluminum Coils for Outer Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

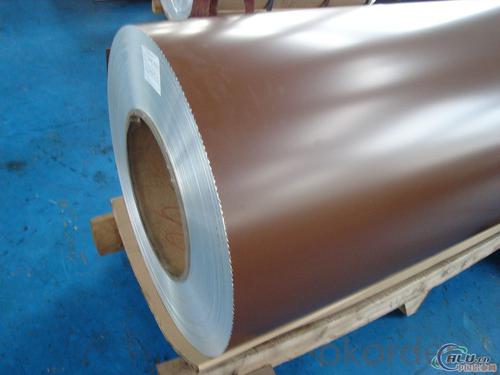

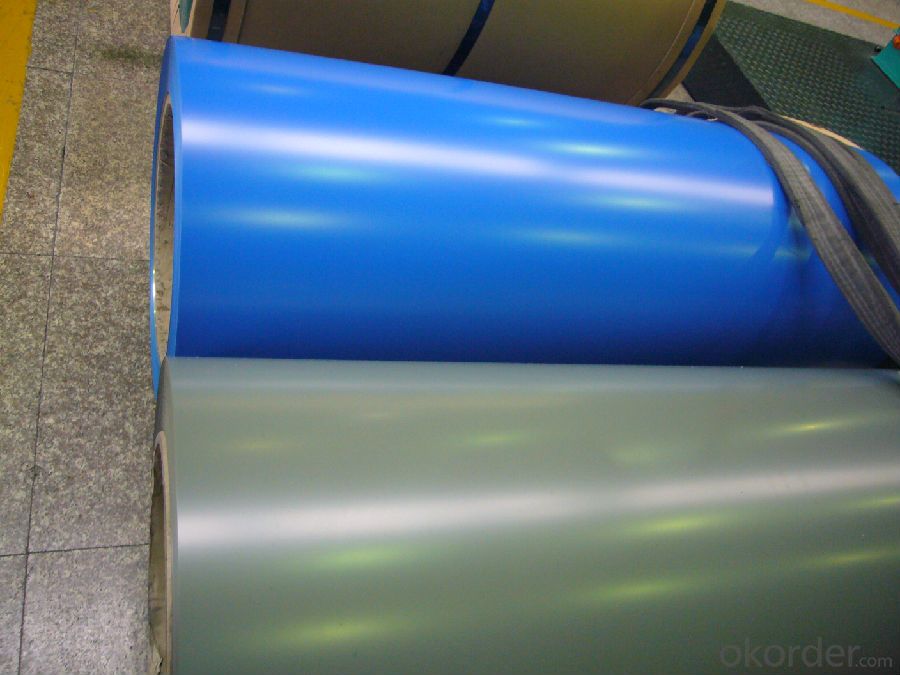

1.Structure of Polyester Coating Aluminium Coils for Outer Wall Curtain

Polyester Coating Aluminium Coils for Outer Wall Curtain are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Polyester Coating Aluminium Coils for Outer Wall Curtain

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Coating Thickness |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 20-25 MICRONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Do 101 aluminum sheets have any specific sound or vibration damping properties?

- Yes, 101 aluminum sheets have specific sound and vibration damping properties. Aluminum is known for its excellent damping characteristics, meaning it can effectively absorb or dampen vibrations and reduce noise levels. This is due to its high density and stiffness, which allow it to dissipate vibrational energy. Additionally, aluminum sheets can be further enhanced by applying sound-damping coatings or treatments, such as adhesive-backed damping sheets or constrained layer damping materials. These treatments can further improve the sound and vibration damping properties of 101 aluminum sheets, making them a popular choice in various industries where noise reduction and vibration control are important considerations, such as automotive, aerospace, and construction.

- Q: Is aluminum sheet recyclable?

- Indeed, aluminum sheet possesses a high recyclability factor. In fact, it ranks among the most sustainable and environmentally conscious materials available. This is due to its unique ability to be recycled endlessly without any compromise to its quality. The process of recycling aluminum sheet involves melting it down until it reaches a liquid state. Interestingly, this process requires far less energy than producing primary aluminum from raw materials. By engaging in the recycling of aluminum sheet, we not only preserve our precious natural resources but also play a crucial role in reducing greenhouse gas emissions and conserving energy. It has been estimated that recycling just one ton of aluminum sheet can save up to nine tons of CO2 emissions. Therefore, embracing the practice of aluminum sheet recycling is not only economically feasible but also a vital step in fostering a sustainable and eco-friendly environment.

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- Aluminum wire isn't used much anymore, partly due to it's tendancy to work harden and get brittle. Most electricians I work with prefer not to use it. I would opt for your thought of installing a junction box and changing to copper wire for the rest of the run. Code would allow this, and it would be good insurance against future trouble with the aluminum wire at the termination of that circuit. Don't forget the anti -ox.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It is also resistant to harsh weather conditions and pests, making it a popular choice for many homeowners and builders. However, it is important to ensure proper installation to maximize its benefits and longevity.</p>

- Q: What is the fatigue limit of aluminum sheets?

- The fatigue limit of aluminum sheets varies depending on various factors such as the alloy, thickness, and surface condition. However, aluminum alloys generally exhibit a relatively high fatigue limit compared to other materials, making them suitable for applications where cyclic loading is involved.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

- Q: What type of aluminum plate does the traffic sign use? 1100?

- Formulated according to unused specifications and design requirements. May refer to the road traffic sign and the marking establishment standard execution.

- Q: What are the common thicknesses of aluminum sheets used in transportation industry?

- Aluminum sheets are widely utilized in the transportation sector for various purposes due to their lightweight, durability, and ability to resist corrosion. In this industry, the thickness of aluminum sheets typically falls within the range of 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). When it comes to automotive body panels, which necessitate a balance between weight reduction and structural integrity, the preferred thickness of aluminum sheets is usually between 0.040 inches (1.02 mm) and 0.063 inches (1.6 mm). These particular thicknesses ensure sufficient strength while effectively reducing the overall weight of the vehicle compared to steel counterparts. In the aerospace field, where weight reduction is of utmost importance, thinner aluminum sheets are commonly employed. Typically, thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are used in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is important to note that the specific thicknesses of aluminum sheets in the transportation industry may vary depending on the particular application, regulatory requirements, and design factors. Thus, it is crucial to consult the relevant industry standards and specifications for accurate information regarding the recommended thicknesses for different transportation applications.

- Q: What are the advantages of using aluminum sheets over other materials?

- There are several advantages of using aluminum sheets over other materials. Firstly, aluminum is lightweight, making it easier to handle and transport. Additionally, aluminum is highly resistant to corrosion, which increases its durability and lifespan. Aluminum sheets also have excellent thermal and electrical conductivity, making them suitable for various applications. Moreover, aluminum is highly malleable, allowing it to be easily formed into different shapes and sizes. Lastly, aluminum is a sustainable and recyclable material, contributing to environmental benefits.

Send your message to us

Black Anodized Aluminum Sheets - Polyester Coated Aluminum Coils for Outer Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords