Aluminum Sheets for Trailers - Aluminum Coils for Color Coated with Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

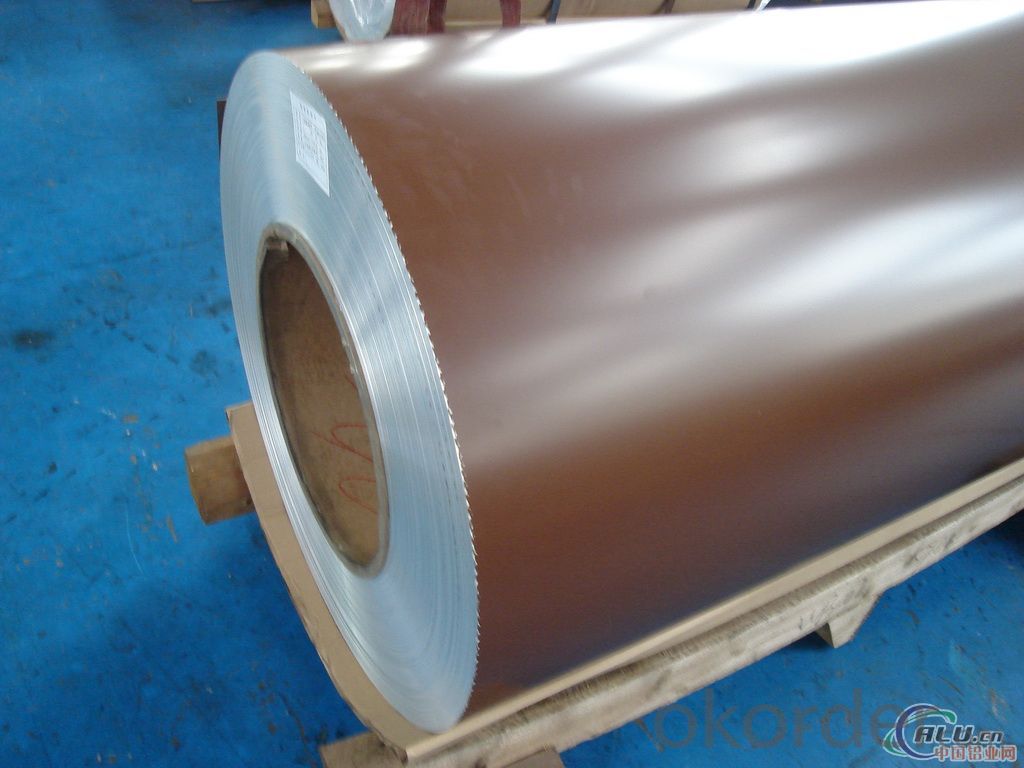

1.Structure of Aluminium Coils for Color Coated with Polyester

Aluminium Coils for Color Coated with Polyester are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Color Coated with Polyester

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Color Coated with Polyester

4. Product Specification of Aluminium Coils for Color Coated with Polyester

| Alloy | Temper | Thickness | Width | Coating Thickness |

| AA3003 | H14 | 0.2-3MM | 1000-1800MM | 20-25 MICRONS |

5.FAQ of Aluminium Coils for Color Coated with Polyester

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the surface treatment requirements for aluminum sheets in the food industry?

- In the food industry, aluminum sheets used for food packaging and handling must undergo specific surface treatments to meet hygiene and safety standards. The surface treatment requirements for aluminum sheets in the food industry typically involve processes like cleaning, degreasing, and anodizing. These treatments remove any dirt, oils, or contaminants, and create a protective layer on the aluminum surface to prevent corrosion and ensure the sheets are safe for food contact. Additionally, the surface treatments may also include specific coatings or laminations to enhance the barrier properties and maintain the quality and freshness of the food products.

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: The radius of an atom of aluminum is 143pm and there are 10^12 in a meter. The aluminum is a 3x3cm square. The density is 2.70 g/cm^3. I found the mass to be 0.03g. I found the volume to be 0.09cm^3

- Good quality standard aluminum foil such as Reynolds brand is 0.007 inches thick. If aluminum atoms are indeed 143 picometers in radius then the foil would be 2,486,713 atoms thick. Of course, the thickness is not controlled to a tolerance of one atom. (Cheaper brands are about 0.0060 to 0.0065 inches thick.) The ionic radius of aluminum is commonly accepted to be 72 pm, and as of 2008 a covalent radius of 121 pm. . .

- Q: What is the maximum width available for aluminum sheets?

- The maximum width available for aluminum sheets varies depending on the supplier and the specific requirements. However, standard widths for aluminum sheets typically range from 36 inches to 72 inches.

- Q: What paint is better to paint on the brushed aluminum sheet? Simple process and good adhesion!

- As long as it is spray paint, adhesion is not the same, if you want to firm, it is better to paint

- Q: Can aluminum sheet be used for aerospace applications?

- Yes, aluminum sheet can be used for aerospace applications. Aluminum is a widely used material in the aerospace industry due to its desirable properties such as lightweight, high strength, and corrosion resistance. It is commonly used in the construction of aircraft fuselages, wings, and structural components. Aluminum sheets are often used in the fabrication of aircraft panels, where their high strength-to-weight ratio allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum sheets can be easily formed, machined, and welded, making them versatile and suitable for various aerospace applications.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: Can aluminum sheets be used for water tanks?

- Yes, aluminum sheets can be used for water tanks. Aluminum is a corrosion-resistant material and is commonly used in the construction of water tanks due to its durability and ability to withstand harsh weather conditions.

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a non-toxic and non-reactive metal that does not leach harmful substances into food. It is widely used in the food industry for packaging, cooking utensils, and food storage containers. Additionally, aluminum exhibits excellent heat conductivity and can be easily cleaned, making it a popular choice for food-related applications.

Send your message to us

Aluminum Sheets for Trailers - Aluminum Coils for Color Coated with Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords