Quick Details

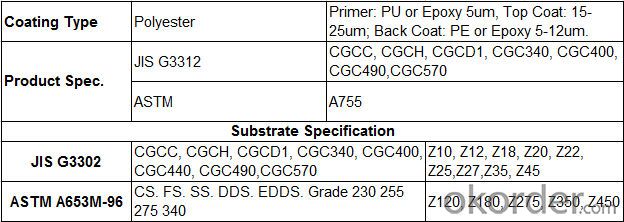

Standard: ASTM, DIN, GB, JIS, AS/NZS 2728

Thickness: 0.15-1.5mm

Brand Name: SIMMIC

type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Width: 750-1534mm

Length: Coil

Packaging & Delivery

Packaging Details: Oscillated wound: one coil per bundle, inner is the protecting humidity-protect humidity-proof wax paper. Medium is plastic film. Outer is sackcloth or compound paper packing. Coil to be laid on single type pallet (one pile per pallet) Delivery Detail: 25days but also depends on the quantity and specification. Specifications

1. Top 2 coat: primer 5uM, top coat 15-20uM.

2. Back 2 coat: primer 2-5uM, back coat 5-20uM.

3. Back 1 coat: back coat 5-10uM.Polyester Coated Pre-Painted

Hot-Dip Galvanized Steel Coil (PPGI)