Quick Details

Standard: ASTM, DIN, GB, JIS, AS/NZS 2728

Thickness: 0.15-1.5mm

Brand Name: SIMMIC

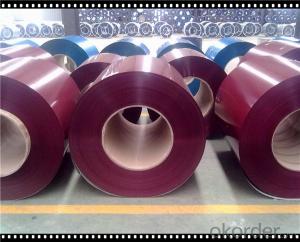

type: Steel Coil

Technique: Cold Rolled

Packaging & Delivery

| Packaging Details: | Oscillated wound: one coil per bundle, inner is the protecting humidity-protect humidity-proof wax paper. Medium is plastic film. Outer is sackcloth or compound paper packing. Coil to be laid on single type pallet (one pile per pallet) |

|---|---|

| Delivery Detail: | 25days but also depends on the quantity and specification. |

Specifications

Building indu Company Work Shop stry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors, rolling doors, booths, shutters, watch rooms, makeshift houses, street waiting room (booth), refrigerators, etc. |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors, screens, ceilings, toilets, interior elevator lobby, stairwayventilating duct, communication pipelines. |